Precision milling services usually provide highly customized machining solutions. Customers can communicate with the service provider according to their specific needs, such as the size, shape, material, and accuracy requirements of the part, and thus receive customized machining services that meet their expectations.

Process

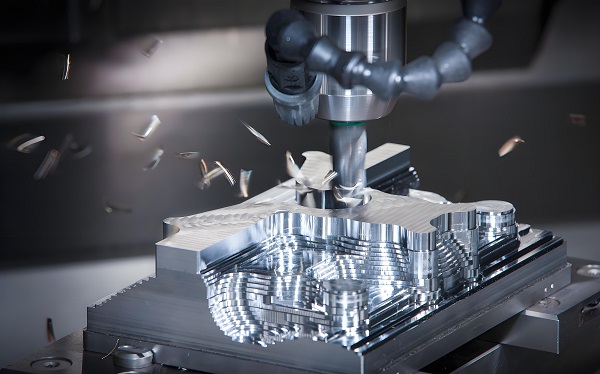

The machining process of precision milling generally includes the following steps:

Workpiece clamping: Before milling begins, the workpiece first needs to be firmly clamped on the machine table to ensure that the workpiece does not move or vibrate during the machining process, thus ensuring machining accuracy.

Tool Selection and Installation: Select the appropriate milling tool according to the machining requirements and install it on the tool holder of the machine tool. The selection of cutting tools directly affects the quality and efficiency of machining.

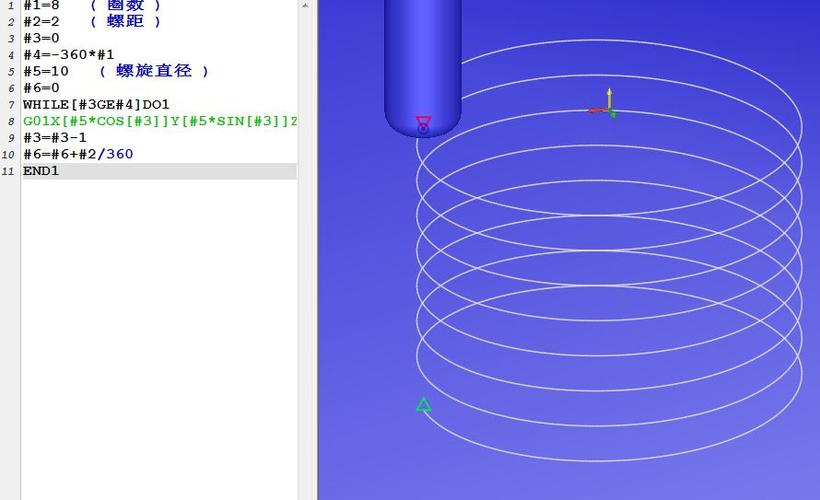

Cutting parameter setting: According to the material of the workpiece, machining accuracy and surface quality requirements, set the appropriate cutting speed, feed and depth of cut and other parameters. The selection of these parameters is essential to ensure the quality of machining and improve machining efficiency.

Milling process control: in the milling process, you need to closely monitor the operating status of the machine tool, tool wear and the quality of the workpiece. According to the actual situation, timely adjustment of cutting parameters or replacement of tools to ensure the smooth progress of the machining process.

Workpiece testing and quality control: after processing is completed, the need for quality testing of the workpiece, such as size measurement, surface roughness testing. According to the test results to determine whether the processing quality meets the requirements, and take appropriate measures for quality control.

Machining products

Precision milling services can process many types of products, including but not limited to mechanical parts, electronic parts, aerospace parts and so on. These products usually have high precision, complex shapes and high quality requirements.

Technical Advantages

Precision milling services offer significant technical advantages:

High Precision: With advanced CNC and precision servo system, it is possible to realize micron or even nano level machining precision.

High efficiency: through programming control, one-time clamping and multi-process machining can be realized, effectively shortening the machining cycle. At the same time, the use of high-speed cutting tools and optimized cutting parameters, making the machining efficiency greatly improved.

High flexibility: with a wide range of machining and powerful machining capacity, it can adapt to the machining needs of various complex shapes and materials.

Fields of application

Precision milling services have a wide range of applications in many fields:

Mold processing: for processing various models to meet the high precision and quality requirements of the mold manufacturing industry.

Mechanical parts processing: such as shafts, gears and other mechanical parts processing, to ensure the dimensional accuracy and surface quality of the parts.

Aerospace field: used for parts manufacturing, repair and improvement, to meet the demand for high-precision and high-strength parts in the aerospace field.

Electronic parts processing: used for processing micro components, such as chips, to meet the requirements of the electronics industry for miniaturization and integration.

Processable materials

Precision milling services can process a wide range of materials, including but not limited to:

Metal materials: such as stainless steel, aluminum alloy, copper, etc.

Non-metallic materials: such as plastics, composite materials, etc.

Product Precision

Precision Milling Services’ products have a very high degree of precision, often reaching micron or even nanometer machining accuracy. This depends on the choice of machine tools, cutting tools and machining parameters used.

Examples of cooperation with international companies

With regard to cases of cooperation with international companies, it is not possible to provide the names or details of specific cases of cooperation, since specific cases may vary from service provider to service provider, and trade secrets may be involved. However, it is certain that precision milling services have a wide range of competitiveness and cooperation opportunities in the international market due to its advantages of high precision, high efficiency and high flexibility.

To sum up, precision milling service has become an indispensable part of modern manufacturing industry with its customized service process, high-precision machining capability, wide range of application fields and cooperation opportunities with international enterprises.