Answer

Yes, brass is excellent for machining. Its combination of softness, high ductility, and self-lubricating properties (due to lead content in alloys like C36000) makes it ideal for precision machining. Brass produces short, easily managed chips, reduces tool wear, and achieves smooth surface finishes (Ra ≤ 1.6 μm) without excessive heat generation. For example, C36000 brass has a machinability rating of 100% (industry benchmark), allowing high-speed machining (up to 2000 SFM with carbide tools) and extending tool life by 3–5 times compared to other materials. It is widely used in automotive connectors, valves, and musical instruments, where both formability and corrosion resistance are critical. However, specific grades (e.g., C23000 for marine applications) must be selected based on environmental and mechanical requirements.

Extended answer

1.Material properties and alloy classification

Core ingredients are balanced with performance

Brass is a copper-zinc alloy, with zinc content typically between 5% and 45%. Adding lead (1.5–3.7% in free-cutting grades like C36000) enhances machinability by acting as a solid lubricant, reducing friction during cutting and preventing built-up edge (BUE) formation 112. Other alloying elements (e.g., aluminum, silicon) improve corrosion resistance (e.g., naval brass for marine environments) or strength (e.g., C35300 for threaded components) .

Tensile Strength: 338–469 MPa (C36000 annealed) .

Hardness: 63–126 HB (C36000), significantly lower than steel (~200 HB) but higher than aluminum (~30 HB).

Thermal Conductivity: 115 W/(m·K), enabling efficient heat dissipation during machining.

Mechanical Properties:

Key Alloy Grades

C36000 (Free-Cutting Brass):

The most widely used grade, with 2.5–3.7% lead. It offers superior machinability, high tensile strength (338–469 MPa), and excellent surface finishes (Ra ≤ 1.6 μm) 312. Ideal for screws, valves, and electronic connectors.

C23000 (Red Brass):

Contains 84–86% copper, providing enhanced corrosion resistance and formability. Used in plumbing fixtures and decorative hardware.

C22000 (Commercial Bronze):

Lower zinc content (~10%) gives it a bronze-like appearance and improved workability. Popular in architectural applications.

Lead-Free Alloys (e.g., C69300):

Replace lead with bismuth or silicon to meet RoHS compliance. While slightly harder (HB 100–130), they maintain 90% of C36000’s machinability.

2.Processing advantages and efficiency improvements

Superior Machinability

Chip Control: Lead particles in C36000 cause chips to break into small segments, preventing tangling and tool clogging.

Tool Life: Carbide tools machining C36000 exhibit 3–5 times longer lifespan compared to steel, with cutting speeds up to 2000 SFM.

Surface Quality: Unmatched in achieving mirror-like finishes (Ra ≤ 0.8 μm) without secondary polishing, critical for medical and optical components.

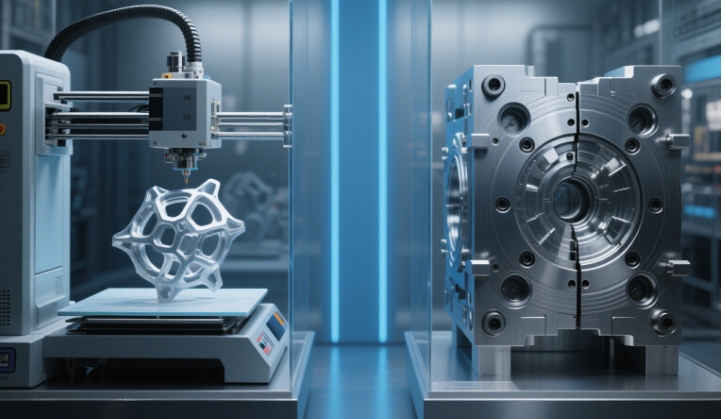

Process Compatibility

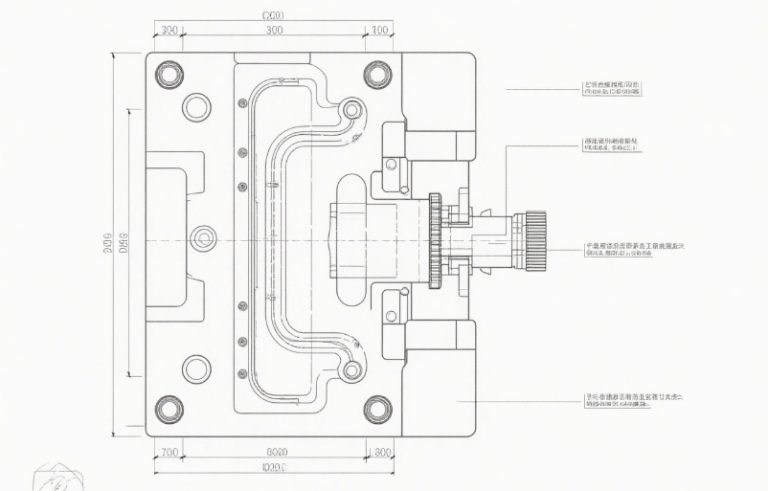

CNC Machining: High feed rates (0.1–0.4 mm/rev) and shallow depths of cut (2–5× feed) optimize efficiency.

Swiss Machining: C36000’s ductility allows intricate geometries (e.g., micro-fittings with ±0.005 mm tolerance).

Hot/Cold Forming: C26000 (70% Cu) can be cold-drawn into wires with 30% elongation, while C35300 withstands hot forging at 650–750°C.

Cost-Effectiveness

Scrap recovery rates exceed 95%, reducing material costs. For example, C36000’s machining cost factor is 0.6 (vs. 1.0 for steel), despite higher raw material prices.

3.Typical areas of application

Industrial & Automotive

Valves & Fittings: C36000’s corrosion resistance and tight tolerances (±0.01 mm) make it ideal for hydraulic components.

Engine Parts: C28000 (high zinc) gears and bearings withstand 200 MPa cyclic loads in automotive transmissions.

Electronics & Communications

Connectors: C36000’s conductivity (26% IACS) and low contact resistance ensure reliable signal transmission in 5G infrastructure.

Heat Sinks: C22000’s thermal conductivity (103 W/(m·K)) efficiently dissipates heat from power modules.

Aerospace & Medical

Aviation Components: C35300 threaded inserts and C23000 bushings meet FAA standards for corrosion resistance in aircraft interiors.

Surgical Instruments: Lead-free C69300 (biocompatible) is used for arthroscopic tools, with Ra ≤ 0.4 μm surface finish.

Consumer Goods & Art

Musical Instruments: C26000’s acoustic properties and malleability are essential for trumpets and saxophones.

Decorative Hardware: C22000’s golden hue and resistance to tarnish make it a choice for luxury fixtures.

4. Optimization of processing technology and parameters

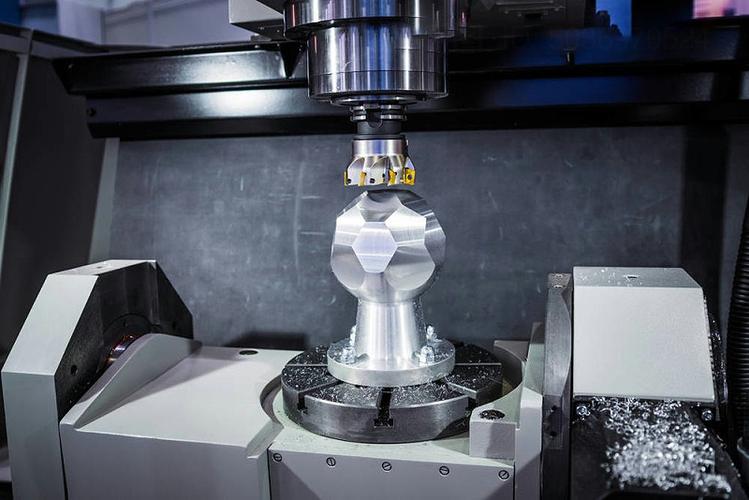

Tooling Recommendations

Cutting Tools: Carbide end mills (coated with TiN or DLC) and HSS drills with 118° point angles are optimal for C36000.

Coolants: Water-soluble emulsions (5–10% concentration) reduce friction and heat, while mineral oils improve surface finish in deep-hole drilling.

Machining Parameters

Turning: 300–900 SFM (carbide) with 0.05–0.15 mm/rev feed.

Milling: 200–600 SFM with 0.03–0.12 mm/tooth feed.

Speed & Feed:

Drilling: 150–400 SFM for C36000, using peck-drilling to evacuate chips.

Post-Processing

Deburring: Vibratory finishing with ceramic media achieves Ra ≤ 0.8 μm, while laser ablation removes micro-burrs in medical devices.

Surface Coating: Nickel plating (5–10 μm) enhances corrosion resistance (salt spray > 1000 hours) for marine components.

5. Comparative analysis with other materials

Aluminum

Advantages: Lighter (2.7 g/cm³ vs. 8.5 g/cm³) and cheaper.

Disadvantages: Lower hardness (30 HB vs. 63 HB) and corrosion resistance. Aluminum’s tendency to gall requires higher cutting speeds (600–1800 SFM) and frequent tool changes.

Steel

Advantages: Higher strength (up to 2000 MPa) and wear resistance.

Disadvantages: Poor machinability (tool life 1/3 of brass) and susceptibility to rust. Machining steel requires aggressive cooling and slower speeds (50–200 SFM) .

Bronze

Advantages: Superior wear resistance (HB 150–250) and low friction.

Disadvantages: Higher cost and lower machinability. Bronze’s brittleness limits its use in complex geometries.

6. Challenges and solutions

Lead Content & Environmental Compliance

Issue: Traditional leaded brass (e.g., C36000) faces restrictions under RoHS and California AB.

Solution: Lead-free alloys (e.g., C69300 with Bi/Si) maintain 90% machinability while meeting Pb ≤ 0.1% standards.

Work Hardening

Issue: Cold working (e.g., threading) can increase hardness by 40% in C36000.

Solution: Annealing at 260–320°C for 1 hour restores ductility without compromising strength.

Chip Evacuation in Deep Holes

Issue: Long chips in deep-hole drilling (e.g., >5× diameter) can damage tools.

Solution: Use high-pressure coolant (5–10 MPa) and helical flute drills with 30° helix angles.

7. Future development trends

Advanced Alloys

Graphene-Reinforced Brass: Recent patents (e.g., Beijing Jinpeng’s composite) report 30% higher tensile strength and 20% improved thermal conductivity.

High-Strength, Low-Lead Alloys: C35300 variants with ≤0.5% lead show HB 120–150 while maintaining 85% of C36000’s machinability.

Automation & Smart Machining

AI-Driven Optimization: Machine learning algorithms predict optimal cutting parameters for brass grades, reducing trial-and-error by 50%.

Robotic Deburring: Collaborative robots (cobots) equipped with force sensors achieve 99.9% burr removal accuracy in valve components.

Sustainability

Closed-Loop Recycling: Scrap brass recovery rates exceed 97% in modern foundries, with energy consumption reduced by 62% compared to primary production.

Eco-Friendly Coatings: Ni-P-TiO₂ nanocomposite plating (2–3 μm) provides 1000+ hours of salt spray resistance without heavy metals.

Brass remains a cornerstone material in precision manufacturing due to its unrivaled balance of machinability, corrosion resistance, and cost-effectiveness. While challenges like lead restrictions and work hardening exist, innovations in alloy design and machining technology (e.g., AI-driven automation, graphene composites) are pushing its boundaries. Whether for aerospace components or consumer goods, brass continues to prove its versatility in demanding applications.