Answer:

CNC machining is not necessarily faster than 3D printing; it depends on the specific working conditions. For regular parts with simple structures and large quantities, CNC machining is faster through high – speed cutting and machining multiple parts in one clamping. However, for single – piece parts with complex hollow structures or personalized customization, 3D printing can quickly manufacture after the design is confirmed without complex tooling, as it forms by layer – by – layer deposition, thus being more efficient. In addition, the type of material and the performance of the equipment also affect the processing speed of the two.

Professional Extension

I. Impact of Part Structure and Processing Quantity on Speed

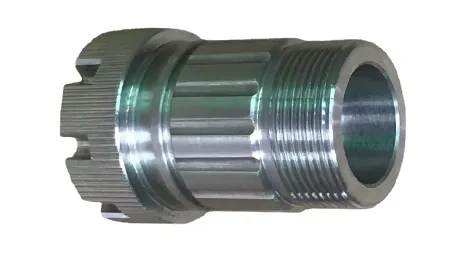

The complexity of the part structure and the quantity of processing are the core factors determining the speed difference between CNC machining and 3D printing. Based on the material removal principle, CNC machining is suitable for processing parts with regular shapes and simple structures. For example, in the mass production of metal bolts, multiple workpieces can be clamped at one time on a CNC lathe. Using high – speed cutting and mature processing techniques, a large number of products can be completed in a short time. But when facing parts with complex internal hollow structures or free – form surfaces, such as the turbine blades of an aero – engine, CNC machining requires multi – axis linkage, multiple roughing and finishing processes, and frequent tool changes and parameter adjustments, resulting in a significant increase in processing time.

3D printing forms parts by layer – by – layer deposition of materials and has a unique advantage in manufacturing parts with complex structures. For example, customized porous bone implants in the medical field, with their complex internal bionic structures, would be extremely difficult and time – consuming to machine with CNC. However, 3D printing can directly form the parts according to the digital model without special tooling. Nevertheless, when processing simple and regular parts, the layer – by – layer deposition characteristic of 3D printing makes its speed much slower than CNC machining, especially in mass production, where the scale advantage of CNC is more obvious.

II. Differences in Material Properties and Processing Technologies

Different materials show different processing speed performances in CNC machining and 3D printing. Regarding metal materials, CNC machining of metals has a mature process system. By selecting appropriate tools and cutting parameters, efficient material removal can be achieved. For example, for aluminum alloys, CNC milling can adopt higher cutting speeds and feed rates to quickly complete part processing. But for materials with high hardness and poor cutting performance such as titanium alloys and nickel – based alloys, the tool wears quickly during CNC machining, and the cutting parameters need to be reduced, leading to a significant decline in processing efficiency.

3D printing of metals usually uses technologies such as laser melting deposition and electron beam melting. Although it can manufacture complex metal parts, during the printing process, to ensure the metallurgical quality and part accuracy of the material, parameters such as laser power and scanning speed need to be strictly controlled, and each layer needs a certain time to cool after deposition, resulting in a relatively slow overall speed. In the processing of polymer materials, the FDM (Fused Deposition Modeling) technology of 3D printing heats and melts plastic filaments for layer – by – layer deposition. For simple parts, the printing speed is relatively fast. However, when CNC machining polymer materials, due to their low hardness and easy deformation, special clamping and cutting processes need to be adopted, and in some cases, the processing speed is restricted instead.

III. Influence of Equipment Performance and Pre – processing Preparation

The performance differences between CNC equipment and 3D printing equipment, as well as the pre – processing preparation work, also affect the processing speed. High – end CNC machining centers have high – speed spindles, fast feed systems, and multi – axis linkage functions, which can improve cutting efficiency when processing complex parts. However, the equipment cost is high, and complex programming, tooling design, and debugging are required before processing. For single – piece or small – batch production, the pre – processing preparation time may account for a large proportion.

3D printing equipment is relatively easy to operate. Just import the digital model into the slicing software to generate the printing path and then start processing, without the need for complex tooling design. However, the printing size and speed of 3D printing equipment are limited by the equipment itself. Large parts may need to be printed in sections and then assembled. Moreover, the printing accuracy and surface quality are often not as good as those of CNC machining. Some parts need a lot of post – processing work after printing, such as grinding, polishing, and heat treatment, which will affect the overall production cycle.

IV. Selection of Application Scenarios and Production Modes

In actual production, the choice between CNC machining and 3D printing is not only based on speed, but their speed advantages vary in different application scenarios. In large – scale production fields such as automotive manufacturing and aerospace, for parts with relatively simple structures and high – precision requirements, CNC machining is still the mainstream processing method due to its stable processing quality and large – scale production capacity. In fields such as product research and development, medical customization, and artistic creation, the rapid prototyping and personalized customization features of 3D printing make it more efficient in single – piece or small – batch production.