Step 1: Define the Terms (To Avoid Confusion)

What Is Permanent Mold Casting?

- Mold material: Steel, cast iron, or other heat-resistant metals (to withstand repeated heating/cooling cycles).

- Metal flow: Relies on gravity, low pressure, or vacuum to fill the mold (no high-pressure injection).

- Compatible metals: Works with non-ferrous metals (aluminum, magnesium, zinc) and some ferrous metals (e.g., cast iron for large parts).

- Typical uses: Mid-volume production (1,000–10,000 units) of parts like aluminum wheels, pump housings, or agricultural equipment components.

What Is Die Casting?

- Mold material: High-strength tool steel (e.g., H13) to handle high pressure and temperatures (up to 700°C for aluminum).

- Metal flow: Uses hydraulic or mechanical pressure to inject molten metal into the die (fast fill times: 0.01–0.5 seconds).

- Compatible metals: Primarily low-melting-point non-ferrous metals (zinc, aluminum, magnesium, copper alloys like A380 or Zamak 3).

- Typical uses: High-volume production (10,000+ units) of small-to-medium complex parts (e.g., automotive sensors, electronics housings, toy components).

Step 2: Why Die Casting Is a Type of Permanent Mold Casting

- Reusable molds: Both use durable, non-disposable molds (steel/iron) that are reused for multiple production cycles (unlike sand casting’s single-use molds).

- Non-ferrous metal focus: Both excel with low-to-moderate melting-point non-ferrous metals (aluminum, zinc, magnesium)—though permanent mold casting can handle some ferrous metals (e.g., cast iron) that die casting cannot.

- Batch production efficiency: Both are designed for repeated part production, with lower per-unit costs as volume increases (unlike 3D printing, which is better for one-offs).

Step 3: Key Differences (Die Casting vs. Other Permanent Mold Casting)

|

Comparison Factor

|

Die Casting

|

Other Permanent Mold Casting (e.g., Gravity)

|

|

Pressure Source

|

High pressure (1,000–15,000 psi) injects metal

|

Gravity (metal flows into mold via gravity) or low pressure (<50 psi)

|

|

Mold Complexity

|

Very complex: Includes gates, runners, vents, and often slides/retractable cores for undercuts

|

Simple to moderate: Fewer cavities; no need for high-pressure components

|

|

Part Complexity

|

Can produce highly complex parts (e.g., micro-channels, thin walls ≥0.5mm)

|

Limited to simpler shapes (no intricate undercuts or ultra-thin features)

|

|

Tolerance & Surface Finish

|

Tight tolerances (±0.05–0.1mm); smooth surface finish (Ra 1.6–6.3 μm)

|

Looser tolerances (±0.1–0.3mm); rougher surface (Ra 6.3–25 μm)

|

|

Production Speed

|

Fast (1–2 minutes per cycle); ideal for high volume

|

Slower (5–20 minutes per cycle); better for mid volume

|

|

Tooling Cost

|

Very high ((10,000–)100,000+ per die)

|

Moderate ((2,000–)20,000 per mold)

|

|

Compatible Metals

|

Only low-melting non-ferrous (zinc, aluminum, magnesium, copper alloys)

|

Non-ferrous + some ferrous (e.g., cast iron, low-carbon steel)

|

Step 4: When to Choose Die Casting vs. Other Permanent Mold Casting

Choose Die Casting If:

- You need high-volume production (10,000+ units): The high tooling cost is amortized over many parts, lowering per-unit costs.

- Your part has complex geometry: Undercuts, thin walls (0.5–3mm), or intricate details (e.g., electronics housings with internal ribs).

- Tight tolerances or smooth surfaces are critical: Die casting avoids secondary machining for most features (saves time/cost).

- You’re using low-melting non-ferrous metals: Zinc, aluminum, or magnesium alloys (the most common die casting materials).

Choose Other Permanent Mold Casting If:

- You need mid-volume production (1,000–10,000 units): Lower tooling costs make it more affordable than die casting for smaller batches.

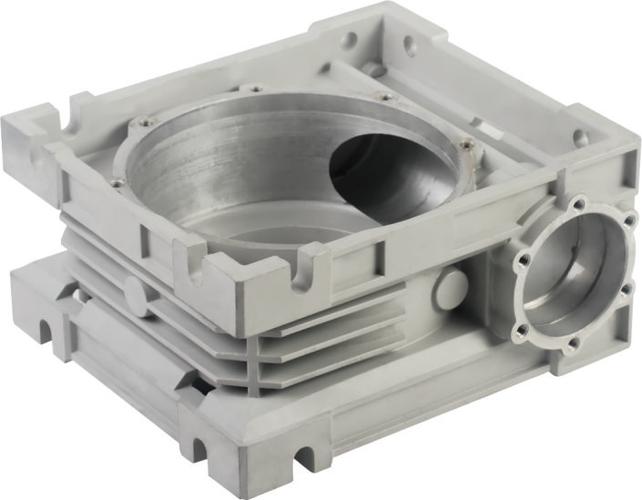

- Your part has a simple shape: No undercuts, thick walls (≥3mm), or intricate details (e.g., a large aluminum pump housing).

- You’re using ferrous metals (e.g., cast iron for a heavy machinery bracket) or higher-melting non-ferrous metals (e.g., some copper alloys).

- You want to minimize upfront investment: Moderate tooling costs ((5,000–)15,000) are easier to justify for smaller runs.

Step 5: Common Myths to Avoid

- Myth: “Permanent mold casting is the same as die casting.”

- Myth: “Die casting can handle all metals that permanent mold casting can.”

- Myth: “Permanent mold casting is always cheaper than die casting.”

Final Takeaway

- High volume + complex parts + low-melting non-ferrous metals: Die casting wins.

- Mid volume + simple parts + ferrous/higher-melting metals: Other permanent mold casting (e.g., gravity) is better.