1、Answer

No, injection molding is not only for plastic. While plastics are the most common materials, the process also works for metals (via metal injection molding, MIM), ceramics (CIM), rubber, and even food materials (e.g., chocolate). Each material requires specialized molds, temperatures, and pressures tailored to its properties.

2、Expansion

Diverse Materials Used in Injection Molding

-

Plastics

- Most Common: Thermoplastics (e.g., ABS, PET, PVC) and thermosets (e.g., epoxy, phenolic resins) are widely used for consumer goods, automotive parts, and electronics.

- Advantages: Low melting points, ease of processing, and endless design flexibility (e.g., transparent lenses, flexible hinges).

-

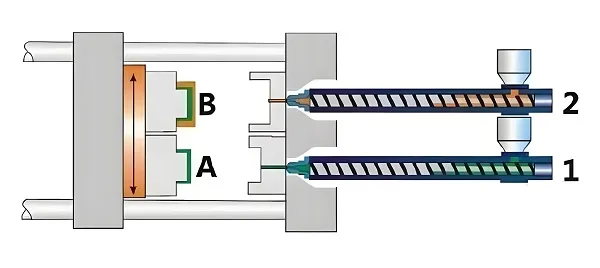

Metals (Metal Injection Molding, MIM)

- Process: Fine metal powders (e.g., stainless steel, titanium, copper) are mixed with a binder, injected into molds, then debound and sintered to form dense metal parts.

- Applications: High-strength, complex-shaped components in aerospace (turbine parts), medical devices (orthopedic implants), and electronics (heat sinks).

- Advantages: Achieves intricate geometries unattainable via traditional machining, with mechanical properties comparable to forged metals.

-

Ceramics (Ceramic Injection Molding, CIM)

- Process: Ceramic powders (e.g., alumina, zirconia) are combined with a polymer binder, injected, and fired at high temperatures to remove the binder and densify the ceramic.

- Applications: High-temperature components (e.g., engine parts), electronic insulators, and medical implants (biocompatible ceramics).

- Advantages: Precision in shapes like dental crowns or aerospace coatings, with resistance to corrosion and extreme heat.

-

Rubber

- Process: Vulcanized rubber (e.g., silicone, EPDM) is heated and injected into molds under high pressure to form seals, gaskets, or flexible parts.

- Applications: Automotive seals, medical tubing, and consumer products (e.g., smartphone cases).

- Key Difference: Requires specialized molds and longer curing times compared to plastic injection.

-

Food and Pharmaceuticals

- Food-Grade Materials: Edible “plastics” (e.g., gelatin, chocolate) or dough are injection-molded into shaped products (e.g., gummy candies, pasta).

- Pharmaceuticals: Injectable drugs or solid dosage forms (e.g., tablet molds) use precision molding for consistent dosing.

Why Non-Plastic Injection Molding Matters

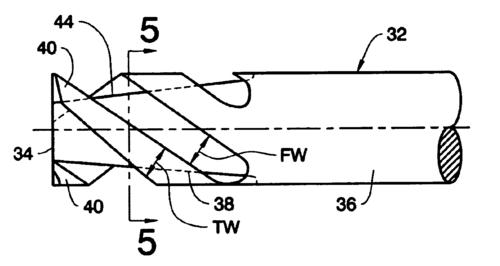

- Engineering Complexity: MIM and CIM enable parts with thin walls, internal channels, or fine features that traditional casting or machining cannot achieve. For example, a turbine blade with cooling channels can only be made via MIM.

- Material Efficiency: Injection molding minimizes waste by using only the material needed for the part, unlike subtractive manufacturing (e.g., CNC machining).

- Scalability: From small batches (e.g., custom ceramic braces) to mass production (e.g., millions of rubber O-rings), the process adapts to volume needs.

Challenges of Non-Plastic Injection Molding

- Higher Costs: Metal and ceramic molds are often made of tool steel or tungsten carbide, costing 2–5x more than plastic molds, and require precise temperature control (e.g., sintering ovens for MIM).

- Longer Cycle Times: Materials like thermoset plastics or rubber need longer cooling/curing times, slowing production compared to fast-cooling thermoplastics.

- Environmental Considerations: Binder removal in MIM/CIM generates chemical waste, though recycling initiatives are improving sustainability.

In summary, injection molding’s versatility extends far beyond plastics, making it a cornerstone in industries demanding high-precision, complex parts from metals, ceramics, or even edible materials.