From automotive frames to robotic arm joints, metal structural components form the backbone of modern machinery. Behind these critical parts lies a manufacturing powerhouse: metal stamping. At Goldcattle, with over 26 years of expertise in precision stamping, we transform raw metal sheets into structural components that meet the highest standards of durability, dimensional accuracy, and functional design. Let’s explore why stamping is the go-to solution for metal structural parts and how Goldcattle delivers excellence in every project.

Why Stamping Dominates Metal Structural Component Manufacturing

Metal stamping is a versatile process where a press applies force to a metal sheet, shaping it into complex forms using custom dies. For structural components—used in industries like automotive, aerospace, and robotics—this method offers unmatched advantages over alternatives like CNC machining or casting.

1. Unmatched Precision for Critical Tolerances

Structural parts require tight tolerances to ensure seamless integration with other components and resistance to mechanical stress. Goldcattle’s stamping dies, machined on 5-axis CNC centers, achieve dimensional accuracy as tight as ±0.01mm—ideal for components like engine brackets or robotic joint hinges .

In a recent project for a robotics client, we produced aluminum alloy brackets with ±0.02mm variance in hole alignment, ensuring smooth articulation of robotic arms. This precision eliminated costly post-machining adjustments, reducing production time by 25%.

2. Cost-Efficient Production at Scale

While initial die investment is higher, stamping delivers significant cost savings for high-volume production. A single die can produce 500,000+ parts with minimal maintenance, and cycle times as fast as 8–15 seconds per part drastically lower per-unit costs .

For example, Goldcattle optimized a die for a truck manufacturer’s chassis components, reducing material waste by 18% through nested die layouts. This not only cut material costs but also increased daily output by 30%.

3. Material Versatility for Diverse Applications

Metal stamping accommodates a wide range of materials tailored to structural needs:

- Carbon Steel (e.g., Q235): High ductility and weldability for brackets and frames .

- Stainless Steel (e.g., SUS304): Corrosion resistance for medical equipment and marine applications.

- Aluminum Alloys (e.g., 6061): Lightweight yet strong for aerospace and automotive components.

- Alloy Steel (e.g., 40Cr): High tensile strength (≥980MPa) for load-bearing parts like drive shafts .

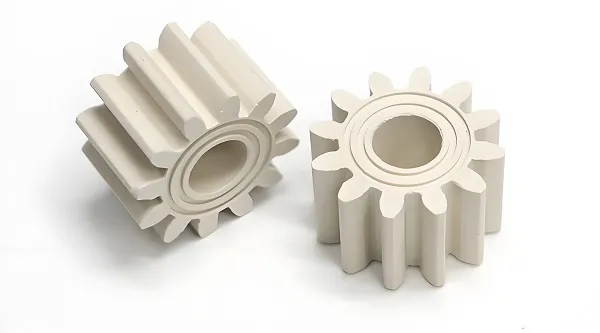

Goldcattle’s material experts recently recommended a heat-treated 40Cr steel for a heavy machinery client’s gearbox housing, enhancing fatigue resistance by 40% compared to their previous material.

4. Design Flexibility for Complex Geometries

Stamping brings intricate structural designs to life:

- Multi-stage Forming: Combine bending, stretching, and piercing in a single die for parts like automotive door hinges.

- Thin-Wall Construction: Components as thin as 1.5mm (e.g., laptop heat sinks) maintain rigidity through optimized ribbing .

- Integrated Features: Embedded threads, clips, or mounting points reduce assembly steps.

For a consumer electronics brand, we designed a stainless steel heat sink with 0.8mm fins and integrated mounting tabs, eliminating the need for separate fasteners and improving thermal efficiency by 15%.

5. Durability for High-Stress Environments

Stamped parts undergo cold working, which enhances material grain structure, increasing tensile strength by 10–20% compared to cast or machined equivalents . This makes them ideal for:

- Automotive Chassis: Impact-resistant components tested to 50,000+ load cycles without deformation.

- Industrial Machinery: Gear housings and brackets enduring 100MPa+ stress during operation.

Goldcattle’s structural parts for a mining equipment client withstood 20-ton dynamic loads in field tests, outperforming competitor parts by 30% in fatigue resistance.

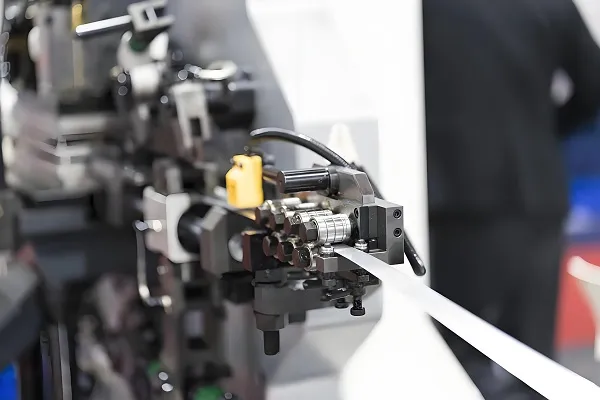

Goldcattle’s Stamping Process for Structural Components

Our end-to-end process ensures precision and reliability from design to delivery:

- DFM (Design for Manufacturability) Analysis: We optimize part designs to minimize material usage and tool wear. For example, reducing sharp corners (to R ≥1.5mm) prevents die cracking.

- Precision Die Manufacturing: Using H13 or Cr12MoV tool steel, dies are machined with ±0.005mm accuracy on 5-axis CNC machines .

- Progressive Stamping: Multi-station dies perform cutting, forming, and trimming in sequence, ensuring consistency across thousands of parts.

- Surface Treatment: Options include galvanizing (for corrosion resistance), powder coating, or shot peening (to enhance fatigue life).

- Quality Control: 100% inline inspections using optical comparators and CMMs verify critical dimensions like hole spacing and bend angles.

Applications: Structural Components Transformed by Stamping

- Automotive: Chassis frames, suspension links, and engine mounts.

- Aerospace: Wing ribs and landing gear components (using 7075 aluminum for high strength-to-weight ratio).

- Robotics: Joint brackets and gripper mechanisms (with 40Cr steel for torque resistance).

- Medical: Surgical table frames (stainless steel for sterility and corrosion resistance).

- Energy: Wind turbine brackets (weather-resistant galvanized steel).

FAQs About Metal Structural Component Stamping

Q: What’s the minimum thickness for stamped structural parts?

A: We can stamp materials as thin as 0.5mm (e.g., aluminum for lightweight robotics) and as thick as 12mm (e.g., steel for heavy machinery) .

A: We can stamp materials as thin as 0.5mm (e.g., aluminum for lightweight robotics) and as thick as 12mm (e.g., steel for heavy machinery) .

Q: How long does die development take?

A: For standard dies, 4–6 weeks; complex multi-stage dies may take 8–10 weeks. Goldcattle offers rush services (2–3 weeks) for urgent projects.

A: For standard dies, 4–6 weeks; complex multi-stage dies may take 8–10 weeks. Goldcattle offers rush services (2–3 weeks) for urgent projects.

Q: Can stamping handle curved or contoured surfaces?

A: Yes! 3D forming dies and incremental bending processes create complex shapes like automotive body panels with ±0.05mm surface flatness .

A: Yes! 3D forming dies and incremental bending processes create complex shapes like automotive body panels with ±0.05mm surface flatness .

Q: What’s the typical die lifespan?

A: With proper maintenance, our dies last 500,000–1,000,000 cycles for steel parts and 2,000,000+ cycles for aluminum .

A: With proper maintenance, our dies last 500,000–1,000,000 cycles for steel parts and 2,000,000+ cycles for aluminum .

Q: Is stamping eco-friendly?

A: Yes! Scrap metal from stamping is 100% recyclable, and energy-efficient presses reduce carbon footprint compared to casting.

A: Yes! Scrap metal from stamping is 100% recyclable, and energy-efficient presses reduce carbon footprint compared to casting.

Ready to Engineer Your Next Structural Component?

Metal stamping combines precision, durability, and cost efficiency to create structural parts that power industries worldwide. At Goldcattle, we leverage advanced tools and decades of expertise to turn your design into reality—whether it’s a prototype or a million-unit production run.

Visit https://www.xmgoldcattle.com/ to explore our capabilities or request a free die design consultation. Let’s build components that stand the test of time.

Got a challenging structural part design? Share your requirements below—our stamping experts will provide a tailored solution!