At the meeting, the customers came into contact with the company’s plastic and metal parts in detail, and the company’s leaders and relevant staff made meticulous answers to all kinds of questions raised by the customers, and the rich professional knowledge and educated working ability also left a deep impression on the customers.

On April 23, 2025, Xiamen Goldcattle Industrial & Trade Co., Ltd. held a pivotal product production meeting, welcoming clients from the automotive, electronics, and industrial equipment sectors. The event focused on in-depth discussions around custom plastic parts, metal components, and precision manufacturing solutions—core areas where Goldcattle has honed 26 years of expertise. Here’s a detailed recap of how the meeting fostered collaboration and highlighted Goldcattle’s strengths in CNC machining, injection molding, and custom part production.

Meeting Background: Aligning Client Needs with Manufacturing Expertise

The attending clients, who design and assemble high-precision machinery, came with specific needs for custom parts: from lightweight plastic washers (critical for electronics insulation) to durable metal stamping components (used in automotive assemblies). Their goal? To verify Goldcattle’s production capabilities, quality control processes, and ability to meet the tight tolerances required—down to ±0.01mm for CNC-machined parts.

As a manufacturer specializing in CNC parts, injection molds, sheet metal parts, and 3D printed components, Goldcattle organized the meeting to bridge the gap between client designs and real-world production. Every detail, from material selection to post-processing, was on the table to ensure alignment with project goals.

Key Discussions: Diving into Plastic & Metal Parts Details

During the meeting, clients toured Goldcattle’s production facility, examining samples such as:

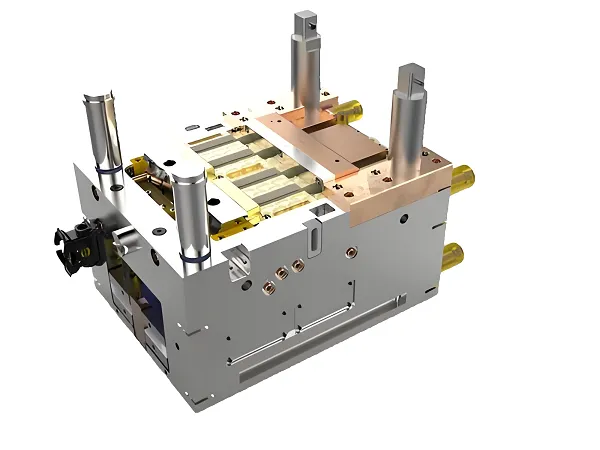

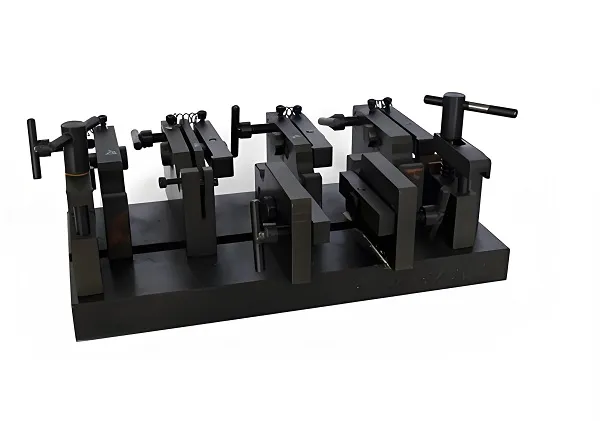

- Custom plastic parts, including thin plastic washers (valued for their insulation and corrosion resistance) and injection-molded components (showcasing complex geometries ideal for electronics).

- Metal components like aluminum stamping parts (lightweight yet strong, perfect for automotive use) and precision CNC-machined metal parts (highlighting high-precision threading and polished surface finishes).

Clients raised targeted questions, including:

- “How do you ensure consistent dimensions for plastic parts during mass production?”

- “Can your metal stamping process handle the high tensile strength needed for our industrial equipment?”

- “What lead times can we expect for custom CNC parts with unique shapes?”

Expert Responses: Showcasing Goldcattle’s Technical Prowess

Goldcattle’s leadership and engineering team—led by Charlie Cheer, head of client solutions—provided concrete, data-driven answers:

- On consistent plastic part dimensions: “For mass production, we use advanced injection molding machines with real-time pressure and temperature monitoring. Post-production, we inspect with CMM (Coordinate Measuring Machines) to keep tolerances within ±0.02mm.”

- On metal stamping strength: “Our CNC-controlled stamping presses (up to 300 tons) work with high-grade aluminum alloys (6061, 5052). We run tensile tests (ensuring ≥200MPa strength) to meet industrial standards.”

- On lead times: “Standard custom CNC parts take 7–10 days. For complex, multi-axis machined geometries, it’s 12–15 days—and we offer rush options if needed.”

Clients praised the team’s “deep technical knowledge” and “practical problem-solving,” noting that Goldcattle’s focus on “design-for-manufacturability” (DFM) helped identify and avoid potential production roadblocks early on.

Outcomes: From Discussion to Actionable Collaboration

By the meeting’s end, two clients agreed to move forward with preliminary plans:

- 5,000 custom aluminum stamping parts for automotive air intake systems.

- A prototype run of CNC-machined plastic threading inserts for electronics assembly.

One client representative noted: “Goldcattle’s 26 years of experience shines through—they didn’t just show us parts; they walked us through optimizing our designs for cost and efficiency. We’re ready to move forward with confidence.”

Ready to Discuss Your Custom Parts Project?

Whether you need CNC-machined components, injection-molded plastics, or sheet metal parts, Goldcattle delivers tailored solutions based on your drawings or samples.

Reach out to Charlie Cheer today:

- Tel: +86-18150097490

- Email: charlie@plasticmetalparts.com

Explore Related Expertise

Dive deeper into the technologies powering our custom parts:

- Custom CNC Plastic Threading Inserts – Precision tools for electronics machining

- CNC Powder Molding Technology Explained – Advanced methods for complex metal parts

- Thin Plastic Washers Overview – Key applications in machinery and electronics

© 2025 Xiamen Goldcattle Industrial & Trade Co., Ltd. – 26 years of excellence in custom parts manufacturing.