Online customized CNC machining parts service is a kind of efficient and precise machining method, through the Internet platform, customers can conveniently customize the required mechanical parts.CNC (Computer Numerical Control) machining technology has become an important part of the modern manufacturing industry due to its high precision, high efficiency, and a wide range of material applicability.

1. CNC machining technology

CNC machining technology is a kind of automated machining technology by controlling machine tools through computer programs. Its working principle includes the following key points:

Computer control: control the movement of the machine tool and the machining process by writing the CNC program (G code).

Motion system: The servo system receives the commands from the CNC program and controls the motion of the machine’s axes (X, Y and Z axes) to achieve precise machining.

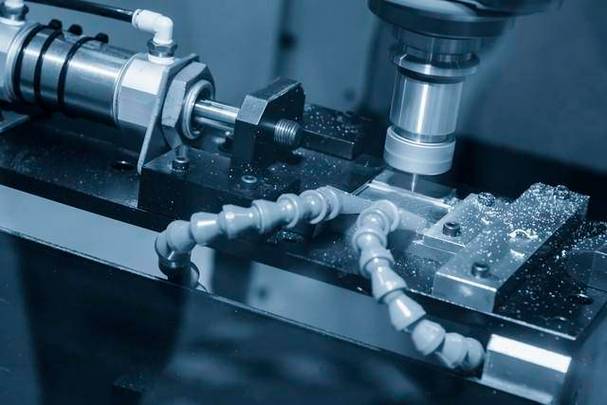

Tooling system: Select the appropriate tool according to the machining requirements and material characteristics, CNC machine tools are usually equipped with automatic tool changing system to improve machining efficiency.

Sensor system: including position sensors, pressure sensors and temperature sensors, etc., for real-time feedback on the status of the machine tool and machining quality, to ensure the safety and accuracy of the machining process.

2. CNC machining materials

CNC machining is applicable to a wide range of materials, including metal, plastic, wood, stone and composite materials.

Metal materials:

Aluminum: light weight, high strength, good thermal conductivity, suitable for aerospace, automotive and other fields.

Steel: high strength, good corrosion resistance and thermal conductivity, widely used in machinery manufacturing.

Copper: good electrical conductivity, commonly used in electrical connectors.

Stainless steel: strong corrosion resistance, suitable for food processing and medical equipment.

Plastic materials:

Polypropylene (PP): lightweight, corrosion-resistant, low cost, commonly used in cups, pots, buckets and other containers.

Polyvinyl Chloride (PVC): good weather resistance, used in construction and piping.

Polytetrafluoroethylene (PTFE): high temperature and corrosion resistant, used for seals and insulation materials.

3. CNC machining capability

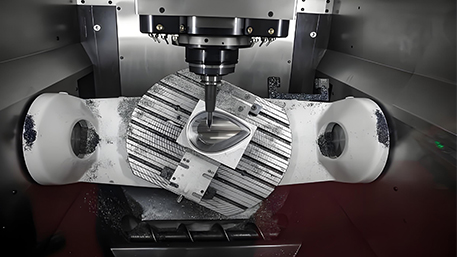

CNC machining capabilities depend on the specifications of the machine tool and the complexity of the machining technology. Common types of CNC machines include 2-axis, 3-axis, 4-axis, and 5-axis machines, each capable of handling parts of varying complexity. For example, 5-axis CNC machines are capable of approaching the workpiece from all directions and are suitable for machining precise and complex parts.

4. CNC machining logic

The CNC machining logic consists of the following steps:

Preparation of CAD models: Create 2D or 3D models using modeling software such as AutoCAD and SolidWorks.

Convert to G-code: Use CAM software to convert the CAD model into G-code recognized by the CNC machine tool.

Setting Machine Parameters: Set the machining parameters of the machine according to the G-code, including tool paths, cutting sequences, etc.

Automated machining: the machine tool carries out automated machining according to the predetermined G-code, including cutting, milling, drilling and other operations.

Quality monitoring: real-time monitoring of the machining process through the sensor system to ensure the quality of machining.

5. Application of CNC machining technology

CNC machining technology is widely used in a variety of industrial fields, including automobile manufacturing, aerospace, electronics manufacturing, and medical devices. Its high precision and automated machining capabilities make it the technology of choice for customized parts and medium volume production.

6. CNC part machining time

CNC part machining time depends on a variety of factors, including part quantity, complexity, material properties, and the equipment and staffing of the machine shop. Generally speaking, small quantities may take a few days, while batch and large quantities may take longer, but automated machining techniques can significantly improve productivity.

7. Advantages of CNC machining

High precision: CNC machining can achieve micron-level accuracy, ensuring the accuracy and consistency of part dimensions.

High efficiency: automated machining reduces manual operations and improves productivity.

Wide material applicability: Suitable for machining a wide range of materials, including metal, plastic and wood.

Strong customization ability: capable of personalized machining according to customer needs to meet diversified demands.

8. Online customized CNC machining service flow

Demand communication: the customer and the processing plant to communicate with the demand, clear size, material, quantity and other requirements of the parts.

Design Confirmation: Processing factory provides design solution according to customer’s demand, and customer confirms it.

Quotation and contract: the processing plant to provide quotations, the two sides signed a contract.

Processing and production: the processing plant according to the contract requirements for CNC machining production.

Quality Inspection: The completed parts are inspected to ensure that they meet the customer’s requirements.

Shipment and after-sales service: Ship the parts to the customer and provide after-sales service support.

9. Why choose Xiamen Goldcattle for customized CNC parts?

Xiamen Goldcattle, as a professional CNC parts processing factory, has the following advantages:

High-quality materials: We use high-quality raw materials to ensure the quality and performance of the parts.

Advanced equipments: We have many advanced CNC machining equipments, which can meet the demand of different complexity of parts machining.

Professional technology: With an experienced technical team, we are able to provide professional technical support and solutions.

Quality Service: Provide full customer service, including demand communication, design confirmation, processing and production, quality inspection and after-sales service.

10. Customers’ comments on Xiamen Goldcattle CNC parts

Customers have highly evaluated Xiamen Goldcattle’s CNC parts machining service for its high machining precision, fast delivery, good service attitude and ability to meet customers’ diversified needs.

Online Customized CNC Machining Parts FAQ

Q1: What is the minimum size for CNC machining?

A1: The minimum size for CNC machining depends on the precision of the machine tool and the specification of the cutting tool. Generally speaking, machining with micron-level precision can be realized.

Q2: How long does the machining cycle take?

A2: The machining cycle time depends on the quantity, complexity and material properties of the part. Generally speaking, small quantity machining may take a few days, while batch and large quantity machining may take longer.

Q3: Can you provide samples for testing?

A3: Yes, we can provide sample testing service to ensure that the quality and performance of the parts meet customer requirements.

Q4: How do you ensure the quality of machining?

A4: We monitor the machining process in real time through strict quality checking process and advanced sensor system to ensure the machining quality meets customers’ requirements.

Online customized CNC machined parts service has become an important part of modern manufacturing industry due to its high precision, high efficiency and wide material applicability. By choosing Xiamen Goldcattle, you will enjoy high quality machining services and superior customer experience.