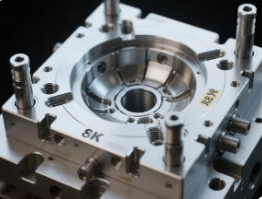

Precise manufacturing is carried out according to the drawings or samples. Our products feature high precision and quality, and comply with relevant international testing standards.

Customize As Required

Process According to Drawings / Samples

CNC / Mould / 3D Printing / Die – casting / Sheet metal / Stamping / Injection molding

![]()

As a national high – tech enterprise, we specialize in CNC precision machining, plastic injection molding, mold design, sheet metal stamping, and 3D printing. We offer one – stop OEM/ODM services for custom metal/plastic parts. From drawings to finished products, we deliver with a high precision of ±0.005mm. We have served over 1000 projects in more than 20 countries around the world.

We support delivery of samples within 7 – 10 days and large – scale orders within 15 – 25 days. For 26 years, we’ve been committed to just one thing: quickly turning your designs into high – quality mass – producible parts.

Customize according to needs and precisely match your automotive requirements.

Individually customize mechanical parts to adapt to various working conditions.

Build according to your needs to meet your personalized riding requirements.

Exclusively crafted hardware components, precisely tailored to fit the usage scenarios.

Tailor - made parts that precisely match the requirements of the equipment.

Customize watch core parts according to requirements, demonstrating the quality of craftsmanship.

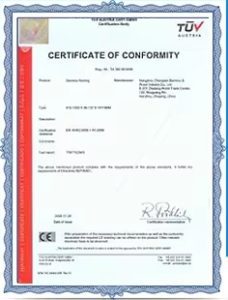

Our factory is a manufacturing and processing plant with 26 years of experience, capable of processing parts and components for various industries. We also have an internationally – recognized website on Alibaba, which has been certified by an authoritative organization. After on – site inspections by a professional third – party company, it has been recognized as a Gold Supplier store.

15 years of experience—let me show you how we make parts stronger and lighter Why Lightweight Sheet Metal Matters in 2026 Let me tell you