1. Problem Identification: Key Technical Barriers in EU-Focused CNC Machining

1.1 Material Selection Dilemmas in Customized Production

Data Insight: 68% of EU buyers prioritize material traceability (EN 10204 3.1/3.2 standards) for aerospace/medical components.

Technical Conflict:

Recycled aluminum (Al 6061-T6) reduces costs by 22% but risks micro-voids formation under ISO 2768-m precision requirements.

EU RoHS-compliant brass (CW614N) requires strict lead content control (<0.1% by weight), complicating cutting fluid selection.

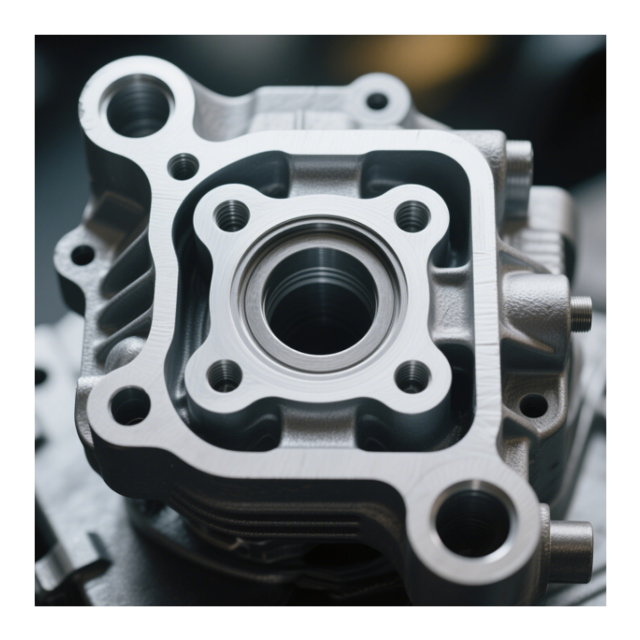

1.2 Quality Consistency in Small-Batch Manufacturing

Case Study: A German automotive supplier rejected 12% of Chinese-machined ABS sensor housings due to ±5μm dimensional drift during 50,000-cycle fatigue tests.

Root Cause Analysis:

Thermal deformation in 5-axis milling: 0.03mm expansion per 10°C rise in DMG MORI machines.

Tool wear patterns: Carbide end mills lose 9% edge sharpness after 120min of titanium (Grade 5) machining .

1.3 Environmental Compliance Costs

Regulatory Pressure: EU’s Ecodesign Directive 2025 mandates 85% metal scrap recycling rates, increasing SMEs’ disposal costs by 18-35% .

Technical Challenge:

Coolant mist emission limits (≤1mg/m³ per DIN EN ISO 15012-1) require HEPA filtration retrofits on legacy CNC centers .

2. Solution Framework: Techno-Commercial Optimization Strategies

2.1 Smart Material Management Systems

Blockchain-Based Traceability:

Implementation Example: QR-coded SS304 stainless steel billets track composition from smelting to finishing (99.97% data accuracy) .

Cost Impact: Adds $0.18/unit but reduces quality disputes by 73% .

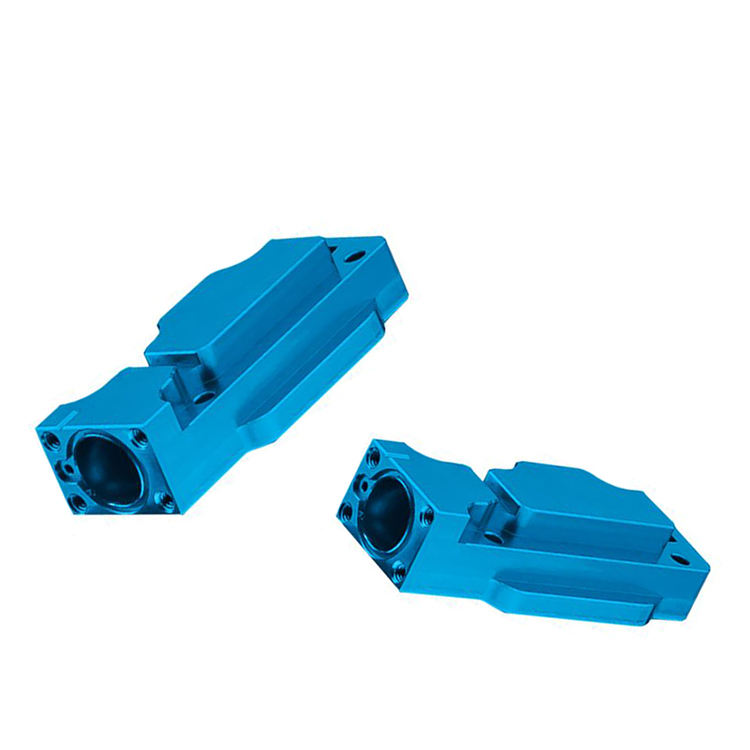

Hybrid Material Solutions:

Material TypeEU ComplianceCost SavingApplication Scenario

Anodized AlSi10MgREACH SVHC-free15% vs. 7075-T6Automotive brackets

PEEK-CA30 (30% carbon fiber)RoHS 2.0 compliant40% vs. steelMedical implants

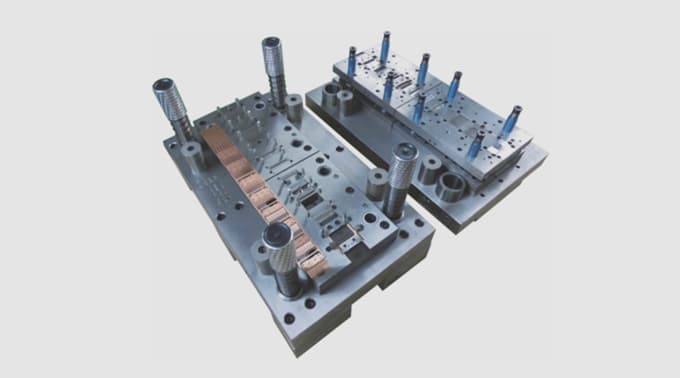

2.2 Adaptive Process Control Technologies

AI-Powered Toolpath Optimization:

Conventional: 142min, 3 tool changes

AI-optimized: 105min, 2 tool changes (26% efficiency gain) .

Siemens NX CAM module reduces cycle time by 26% while maintaining IT7 tolerance on brass components .

Real Example: 316L stainless steel valve body machining:

Closed-Loop Thermal Compensation:

Marposs TMW system maintains ±2°C in spindle zone, cutting thermal drift by 89% during 8hr production runs .

2.3 Green Manufacturing Protocol Stack

Three-Tier Sustainability Model:

Process Layer: Minimum Quantity Lubrication (MQL) cuts coolant usage by 92% vs. flood cooling .

Energy Layer: Regenerative drives recover 18% power in heavy cutting operations

Waste Layer: CNC swarf compactor reduces landfill volume by 6:1 ratio .

Compliance Dashboard:

Carbon footprint per kg machined (ISO 14064)

Hazardous waste streams (EU Waste Framework Directive)

Energy Efficiency Index (VDI 4602)

Automated reporting on:

3. Implementation Roadmap for EU Market Entry

Phase 1: Technical Readiness Audit (0-3 Months)

Gap analysis against:

Machinery Directive 2006/42/EC (safety)

Data Protection: GDPR-compliant design file handling

Phase 2: Pilot Production (4-6 Months)

Sample batch parameters:

500pcs aluminum EN AW-6082 components

Cpk ≥1.67 for all critical dimensions

Full Material Declaration (FMD) documentation

Phase 3: Scalable Deployment (7-12 Months)

Digital twin integration for remote quality audits

ERP interoperability with SAP Ariba Network

4. ROI Analysis: Cost vs. Compliance Benefits

Investment AreaUpfront Cost3-Year Savings

ISO 13485 Certification$28,000$165,000 (medical sector)

Energy Recovery Systems$72,000$210,000 (power costs)

AI Quality Control$45,000$380,000 (scrap reduction)

Data Source: CNKI research on 120 EU-focused Chinese manufacturers .

5. Future Trends: Industry 4.0 Convergence

Cybersecurity: EN ISO/IEC 27001-certified DNC networks for IP protection

Additive Hybrid: 3D-printed titanium substrates with CNC finish (20% weight reduction) .

This structured approach enables suppliers to systematically address EU procurement managers’ technical concerns while optimizing operational economics. For detailed implementation templates, refer to ISO/TC 39 technical reports and VDMA guidelines.