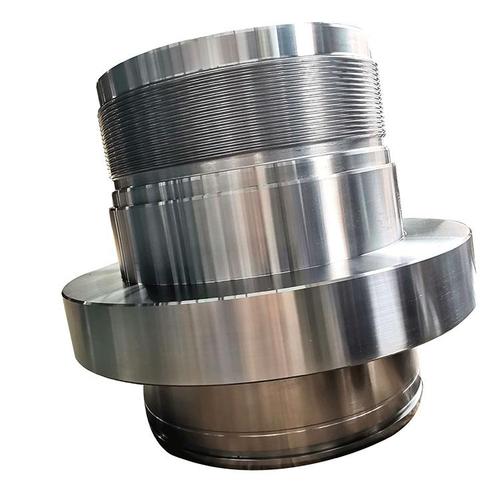

Precision small parts turning is a high-precision, high-efficiency metal machining method that achieves extremely high dimensional accuracy and surface finish by rotating the workpiece and utilizing a tool to make micro cuts. This method is widely used in the manufacture of a variety of precision mechanical parts, such as shafts, holes, threads, and high-precision optical components such as mirrors. Precision small parts turning can meet the strict requirements of high-tech fields on the quality, performance and reliability of parts, is an indispensable part of modern industrial manufacturing.

1.Precision small parts turning production process

Process design: according to the parts drawings and technical requirements, develop a detailed turning process program, including cutting parameters, process routes, tool selection.

Material preparation: select the metal materials that meet the process requirements, to ensure that the material quality is stable and in line with the use of parts environment.

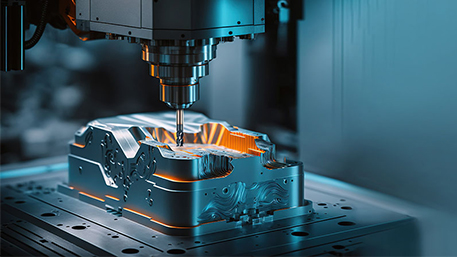

Machine tool and tool selection: according to the size, shape and processing requirements of the parts, select high-precision lathes and suitable tools to ensure cutting performance and durability.

Workpiece clamping: Clamp the workpiece on the machine tool to ensure that the axis of the workpiece coincides with the axis of the lathe spindle to avoid vibration and deformation during machining.

Tool Adjustment: Adjust the cutting parameters of the tool, such as depth of cut, feed rate, tool angle, etc., to ensure that the cutting process is stable and efficient.

Turning Processing: Start the machine tool for roughing, semi-finishing and finishing, gradually removing excess material to achieve the predefined size and surface finish.

Inspection and trimming: Use high-precision measuring tools to inspect the size, shape and surface finish of the machined parts, and trim them if there are defects.

Cleaning and painting: the qualified parts are cleaned and painted to improve the corrosion resistance and appearance quality of the parts.

2.Customized turning of precision small parts

Customer demand analysis: communicate with customers to understand the specific use of parts, working environment, dimensional accuracy and surface finish requirements.

Design program development: according to customer needs, develop a detailed turning process program, including material selection, tool type, cutting parameters, etc..

Sample production and testing: produce sample parts, and conduct performance testing and inspection to ensure that they meet the requirements of customers.

Mass production: after the sample test is qualified, mass production is carried out to ensure that each part meets the design requirements.

After-sales service: provide technical support and after-sales service to solve the problems encountered by customers in the process of use.

3.Precision small parts turning materials

Material:

ZCuSn10Pb5

ZCuZn38Mn2Pb2

ZCuSn10Pb1

PEEK (polyether ether ketone)

Properties:

ZCuSn10Pb5: strong corrosion resistance, especially for dilute sulfuric acid, hydrochloric acid and fatty acids have good corrosion resistance, suitable for the manufacture of corrosion-resistant, acid-resistant fittings.

ZCuZn38Mn2Pb2: excellent mechanical properties, good wear resistance, good cutting performance, suitable for the manufacture of structural materials and wear-resistant parts.

ZCuSn10Pb1: high hardness, excellent wear resistance, not easy to produce the phenomenon of biting, with good cutting performance, suitable for high loads and high sliding speed under the work of wear parts.

PEEK: high-performance thermoplastic, with strength and hardness close to metal, while having good toughness and wear resistance, suitable for aerospace, medical equipment, automotive electronics and other fields.

4. Turning characteristics of precision small parts made of different materials

Products:

ZCuSn10Pb5 precision small parts

ZCuZn38Mn2Pb2 precision small parts

ZCuSn10Pb1 precision small parts

PEEK thin-walled precision small parts

Data:

ZCuSn10Pb5: hardness HB≥100, tensile strength≥390MPa, elongation≥10%.

ZCuZn38Mn2Pb2: hardness HB≥80, tensile strength≥420MPa, elongation≥12%.

ZCuSn10Pb1: hardness HB≥130, tensile strength≥450MPa, elongation≥8%.

PEEK: density 1.32g/cm³, tensile strength 93MPa, bending strength 142MPa, long-term use temperature up to 250 ℃.

Customized Precision Small Parts Turning FAQ

Q1:How much accuracy can be achieved in precision small parts turning?

A1: The accuracy of precision small parts turning can reach micron level or even higher. The specific accuracy depends on the precision of the machine tool, the quality of the tool and the optimization of the cutting parameters.

Q2: What materials are suitable for precision small parts turning?

A2: Materials suitable for precision small parts turning include various copper alloys, aluminum alloys, stainless steel and high-performance plastics such as PEEK. The specific selection depends on the use of the environment and performance requirements of the parts.

Q3: How long is the mass production cycle for precision small parts turning?

A3: The mass production cycle depends on the number of parts, complexity and process requirements. Generally speaking, it takes several weeks to several months from design to completion of mass production.

Q4: What is the cost of precision small parts turning?

A4: The cost of precision small parts turning depends on a number of factors, including material cost, investment in machine tools and cutting tools, process complexity, and production quantities. Generally speaking, high precision and high performance materials and processes will increase the cost.

Through the above introduction, I believe you have a better understanding of precision small parts turning. If you have any questions or needs, please feel free to contact us.