25 Years of Injection Molding Expertise · EV Charger Housing Customization — One-Stop Service from Design to Mass Production

As a high-tech enterprise with 25 years of precision injection molding experience, we provide end-to-end customization services for electric vehicle (EV) charger housings. Equipped with German KraussMaffei injection molding machines and Swiss ARBURG multi-component systems, we adhere to ISO 9001 quality management from material R&D and mold design to production, ensuring compliance with UL, CE, and other international standards.

✅ Material Solutions:

- ABS (high toughness, impact strength ≥18kJ/m²)

- PC+ABS Alloy (120℃ heat resistance, UL94 V-0 flame retardancy)

- PP (chemical corrosion resistance, 15% weight reduction via low density)

Free material UL Yellow Card and flame-retardant test reports available.

✅ Design Freedom:

- Precise positioning for fast-charging interfaces (CCS/CHAdeMO/GB/T)

- Optimized cooling hole design (aerodynamic simulation reduces thermal resistance by 10%)

- Waterproof structures (IP67 standard, IP69K customization available)

✅ Surface Treatments:

- Matte texture (Ra1.6–Ra3.2) for improved grip

- Metallic electroplating (thickness ≥0.5μm, salt spray test >72 hours)

- Laser engraving (permanent marking, friction resistance grade 4)

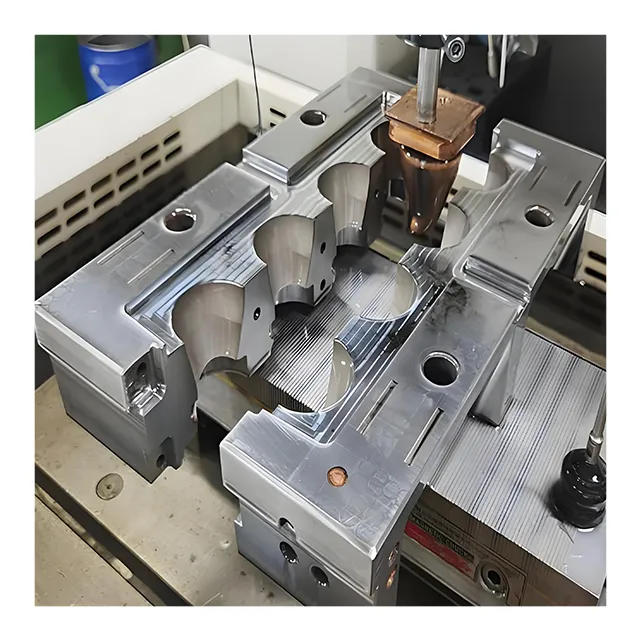

🔧 Equipment Advantages:

- German KraussMaffei CX Series (clamping force 100–500 tons)

- Swiss ARBURG multi-component systems (support 3-color co-injection)

- Coordinate measuring machines (CMM, inspection accuracy ±0.005mm)

💡 Technical Support:

- Moldflow analysis (optimizes gate location to reduce sink marks)

- 15-person R&D team (structural strength FEA analysis provided)

- Free DfM (Design for Manufacturability) consulting

🌍 Global Services:

- Sample delivery via DHL/UPS (3–5 days)

- Bulk orders FOB Shanghai/Ningbo, EXW/DDP terms supported

- 12-month quality guarantee with lifetime maintenance

-

Submit Requirements:

- Upload 3D models (STP/IGS) or describe size/material needs

- Specify application scenarios (home/commercial/vehicle-mounted)

-

Solution Evaluation:

- Material selection suggestions within 48 hours

- Mold plans and quotations issued within 72 hours

-

Sample Confirmation:

- Sample production completed in 7–10 days

- Includes sample inspection reports (dimensions/appearance/performance)

-

Bulk Production:

- First batch delivery within 20–35 days after mold approval

- Support small-batch trial production (500–1,000 pieces)

(Note: For EV charger housing drop test videos, flame-retardant certification reports, or factory tours, message us to request materials!)