Custom Acrylic Large Lamp Covers Plastic Outer Shells

| Attribute | Details |

|---|---|

| Product Name | Acrylic Lamp Covers & Plastic Lamp Shells Customization Service |

| Core Materials | Acrylic (PMMA), ABS, PC, PS, PETG (High-transparency/flame-retardant/UV-resistant materials supported) |

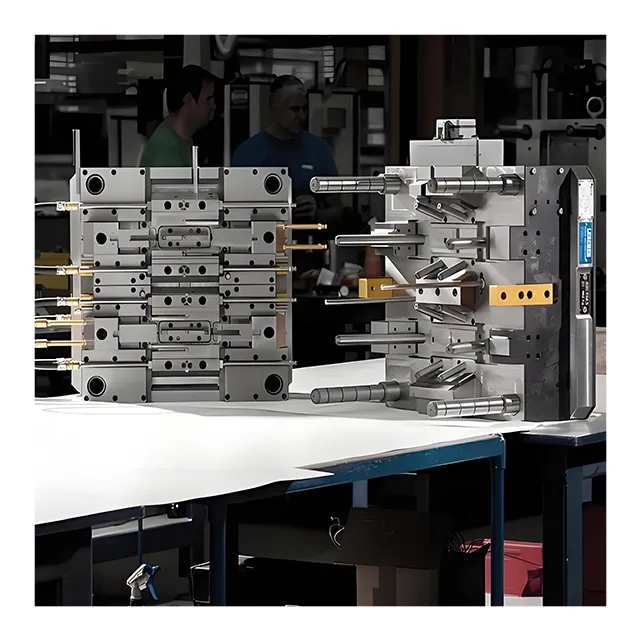

| Core Processes | Injection Molding, CNC Engraving, Heat Bending, Laser Cutting/Engraving, UV Printing, Electroplating/Coating |

| Customization Options | Size (Diameter 50–1000mm), Shape (Round/Square/Irregular), Transparency (30%–95%), Surface Texture (Matte/Matte/Laser), LOGO Customization |

| Surface Treatments | Polishing, Silk-Screen Printing, Electroplating (Champagne Gold/Antique Bronze), Oxidation Coloring, Anti-Fingerprint Coating, IMD |

| Certifications | ISO 9001, RoHS, CE (Lighting Certification) |

| Minimum Order Quantity (MOQ) | Samples: 1 piece, Bulk orders: 500+ (Small-batch trial production negotiable) |

| Packaging | Pearl Cotton + Carton (Fragile item reinforced packaging), Custom color box/label design supported |

| Lead Time | Samples: 7–10 days, Bulk orders: 20–35 days (Expeditable to 15 days) |

| Services | OEM/ODM Customization, Drawing-Based Processing (Supports STP/IGS/DWG), Sample Replication, 3D Printing Prototyping |

| Application Areas | Household Chandeliers, Commercial Lighting, Hotel Project Lights, DIY Handmade Lamps, Industrial Equipment Indicator Lights |

| Origin | XiaMen, China |

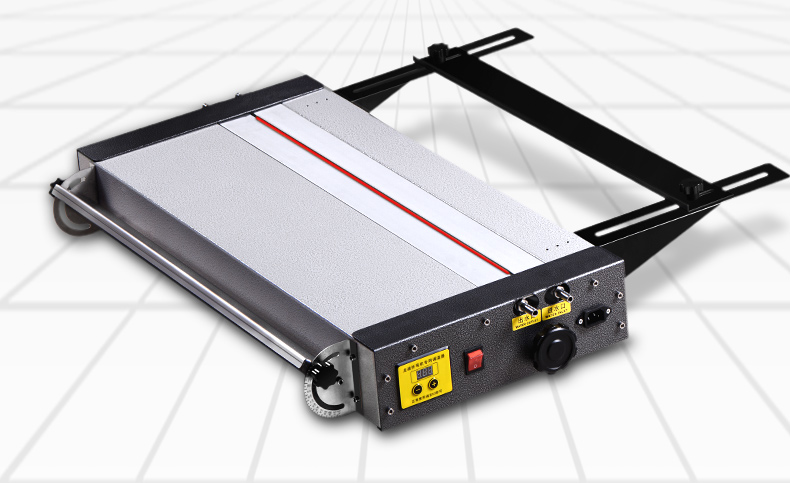

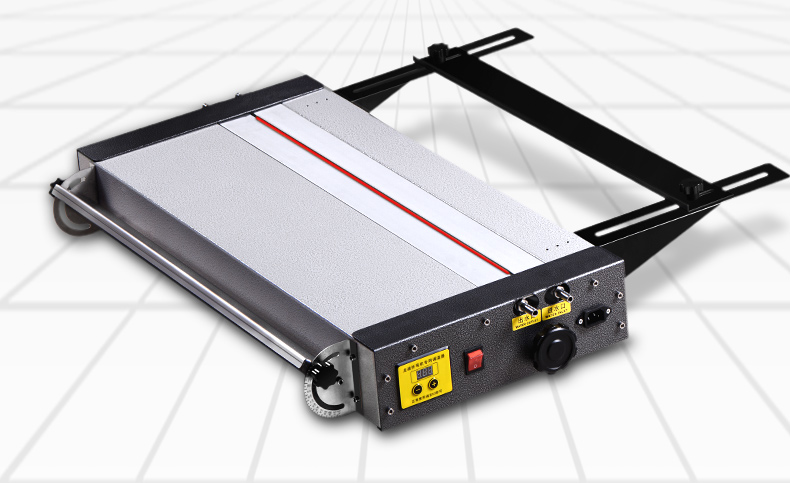

| Equipment Advantages | Full-automatic heat bending production line (precision ±0.5mm), 5-axis laser engraving machine (minimum hole diameter 0.2mm) |

Description

Our Acrylic Lamp Covers – They’re Not Your Average Covers

Why Acrylic? Because Glass is So Last Century

Dude, acrylic (PMMA) is where it’s at! This stuff is like glass but better – lighter, stronger, and way more versatile.

Our custom lamp covers are perfect for:

- Large Lighting Fixtures: Bro, we make covers that are huge – perfect for commercial spaces

- Custom Designs: Need a specific shape? We got you covered (pun intended)

- LED Compatibility: These covers work seamlessly with LED lights – no yellowing here!

- Durable Construction: 17 times stronger than glass – these things can take a beating!

Fun fact: Our acrylic has a 92% light transmittance – that’s almost as clear as glass but way safer!

Materials – We Use the Good Stuff

PMMA Acrylic – The Star of the Show

Bro, PMMA (Polymethyl Methacrylate) is the real deal. This isn’t your cheap plastic – this is high-grade acrylic that looks and performs like glass.

Key Properties:

- Light Transmittance: 90-92% – almost as clear as optical glass!

- Impact Resistance: 17 times stronger than glass – safety first, am I right?

- Weight: 50% lighter than glass – easy to install, no heavy lifting!

- UV Resistance: With anti-UV coating – no yellowing for 5-8 years!

- Heat Resistance: Up to 80°C – handles LED heat like a champ

Pro tip: Avoid cheap acrylic – it yellows in months. Our high-grade PMMA stays crystal clear for years!

Material Comparison – Acrylic vs Others

| Property | Acrylic (PMMA) | PC | Glass |

|---|---|---|---|

| Light Transmittance | 90-92% | 85-90% | 90-92% |

| Impact Resistance | 17x glass | 250x glass | 1x (fragile) |

| Weight | 50% lighter | 60% lighter | Heavy |

| UV Resistance | Excellent | Good | Excellent |

Verdict: Acrylic is the sweet spot – great clarity, lightweight, and affordable!

Our Manufacturing Process – We Don’t Cut Corners

Material Selection

Only high-grade PMMA sheets

CNC Cutting

Precision cutting to exact dimensions

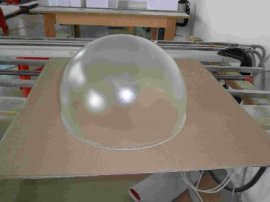

Thermoforming

Heating and shaping into 3D forms

Polishing

Edge polishing for crystal clarity

Quality Control

Strict inspection before shipping

Thermoforming – The Magic Behind 3D Shapes

Bro, thermoforming is where the magic happens! We heat the acrylic sheet to 160-180°C until it’s flexible, then mold it into whatever shape you need.

This process allows us to create complex 3D shapes that would be impossible with glass or other materials.

Fun fact: Our thermoforming machines can handle sheets up to 2000mm x 3000mm – perfect for those huge lamp covers!

Standards & Certifications – We Play By The Rules

Industry Standards We Follow

- IEC/TR 62778: Photobiological safety of lamps and lamp systems

- GB 50034-2024: Building lighting design standards (China)

- ASTM D256: Izod impact resistance testing

- GB/T 1043: Impact strength testing (China standard)

- GB/T 9341: Flexural strength testing

- UL 94: Flammability testing for plastic materials

Pro tip: Always check if your lamp covers meet safety standards – especially for commercial use!

Our Certifications

These aren’t just fancy stickers – they’re proof that our products meet international safety and quality standards.

Every batch of lamp covers undergoes rigorous testing to ensure compliance with all relevant standards.

Test Data – The Proof Is In The Numbers

DISCLAIMER: All test data below is for reference only. Actual results may vary based on specific product specifications.

Mechanical Properties

| Property | Test Result | Standard |

|---|---|---|

| Impact Strength | ≥17 KJ/m² | GB/T 1043 |

| Flexural Strength | ≥98 MPa | GB/T 9341 |

| Tensile Strength | ≥75 MPa | GB/T 1040 |

| Elongation at Break | ≥33% | GB/T 1040 |

Optical & Thermal Properties

| Property | Test Result | Unit |

|---|---|---|

| Light Transmittance | 91.5 | % |

| Heat Deflection Temp | 85 | °C |

| Self-Ignition Temp | 449 | °C |

| Smoke Density Rating | 3.8 | % |

Performance You Can Trust

- UV resistance: No yellowing for 5+ years

- Thermal stability: -40°C to 80°C operating range

- Weather resistance: Suitable for outdoor use

- Chemical resistance: Resists common cleaning agents

- Flame rating: UL 94 V-2 classification

Key Features – Why Our Covers Are Better

Super Durable

17 times stronger than glass – these covers can take a beating without breaking

Crystal Clear

92% light transmittance – your lights will shine brighter than ever before

UV Protected

Anti-UV coating prevents yellowing – stays clear for 5-8 years

Custom Shapes

We can make any shape you need – no design is too complex

Lightweight

50% lighter than glass – easy to install, no heavy lifting required

Heat Resistant

Handles up to 80°C – perfect for LED lighting systems

Applications – We Do It All

Commercial Buildings

Offices, malls, hotels – large scale lighting solutions

Residential

Modern homes, apartments, luxury villas

Healthcare

Hospitals, clinics, medical facilities

Education

Schools, universities, training centers

Industrial

Factories, warehouses, production facilities

Entertainment

Theaters, stadiums, amusement parks

Why Choose Us? – Let Us Count The Ways

26 Years of Experience

Bro, we’ve been making acrylic products since 1999! That’s not just experience – that’s expertise.

We’ve perfected our craft over the years, and we know exactly what works and what doesn’t.

Customization Experts

Need a specific shape, size, or color? We can make it happen. No design is too complex for us.

Our team works with you to create exactly what you need – no compromises.

Quality Guaranteed

Every product undergoes strict quality control. We don’t ship anything we wouldn’t use ourselves.

If you’re not happy, we’re not happy – it’s that simple.

Ready to upgrade your lighting?

Let’s Create Something Amazing

We’re here to help you with all your acrylic lamp cover needs

Phone

++86-18150097490

charlie@plasticmetalparts.com

Location

Xiamen, China