Custom Carbide Chuck Reamers for CNC Machining Centers

Place of Origin : Fujian, China

Type : Broaching

Micro Machining or Not : Not Micro Machining

Model Number : CMP-A9

Brand Name : JSD

Product name : CNC Machine tool reamers

Material : Customers’ Requirement

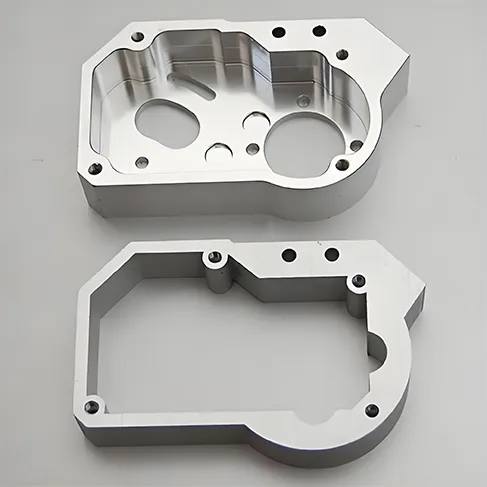

Process : Cnc Machining + Surface Treatment

Surface treatment : Painting\Powder Coating\Plating\Polishing

Service : Customized OEM

Equipment : 3/4/5 Axis CNC Machining Center

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Certification : ISO9001

Tolerance : 0.01- +/-0.005mm

OEM/ODM : OEM ODM Non-standard Processing

Description

1. Products

Welcome to our custom carbide chuck reamer page! Designed for high-precision and high-efficiency metalworking needs, this reamer is made of top-grade carbide, combined with an advanced manufacturing process that ensures the ultimate in precision and surface finish with every cut. Whether it’s in aerospace, automotive, mold and die machining or precision mechanics, it’s a great addition to your production line.

2. Product Specifications

Diameter range: Φ3mm to Φ100mm, can be customized according to specific needs.

Length: Standard length from 100mm to 300mm, special length can be customized.

Number of blades: single, double or multiple blades are available to meet different machining requirements.

Accuracy: IT5 to IT7, ensuring high precision machining.

Coating: TiN (Titanium Nitride), TiAlN (Titanium Aluminum Nitride) and other coatings are available to improve wear resistance and service life.

3. Product materials

We use high-quality cemented carbide (also known as tungsten steel) as the main material, which has high hardness, high strength, high wear resistance and high thermal stability, and is able to maintain excellent cutting performance and tool life under high-speed cutting and heavy load conditions. At the same time, according to different machining materials and machining conditions, we provide a variety of materials of cemented carbide to choose, in order to meet the diversified needs of customers.

4. Product Process

Precision grinding: Advanced 5-axis CNC grinding machine is used for precision grinding to ensure the geometric and dimensional accuracy of the tools.

Coating technology: Applying advanced physical vapor deposition (PVD) or chemical vapor deposition (CVD) technology to form a uniform and dense coating on the surface of the tool, which enhances the wear and corrosion resistance of the tool.

Quality Inspection: Each reamer undergoes strict quality inspection before leaving the factory, including hardness test, edge sharpness check and cutting performance test, to ensure that each tool can be optimized for use.

5. Product use

High-precision hole machining: suitable for precision hole machining of various materials, such as stainless steel, cast iron, non-ferrous metals, etc.

Mold Manufacturing: In the process of mold manufacturing, it is used to process mold cavities, holes, etc. to ensure the precision and life of the mold.

Aerospace: In the aerospace field, it is used to process high-precision engine components and structural parts.

Automotive parts: In the automotive manufacturing industry, it is used to process precision holes in key components such as engine blocks and gearboxes.

6. Product customization

We provide comprehensive customization services, including but not limited to:

Size customization: according to your specific needs, customize the diameter, length, number of cutting edges and other parameters of the tool.

Material selection: recommend the most suitable carbide material according to your machining materials and conditions.

Coating customization: according to your machining needs, choose the most suitable coating type and thickness.

Special design: If there is a need for reamers with special shape or structure, we can provide design consultation and customized production.

Product FAQ

Q1: How do I determine the size of reamer I need?

A: Please provide the exact diameter, length and number of edges required according to your machining drawings or workpiece dimensions. Our engineers will further confirm and adjust for you.

Q2: What are the advantages of carbide reamers over other materials?

A: Carbide reamers have high hardness, high wear resistance and high thermal stability, which can maintain long service life and stable cutting performance under high speed cutting and heavy load conditions.

Q3: What is the lead time for customized reamers?

A: The delivery lead time depends on the specific customization requirements and production arrangement, usually the production is completed and shipped within 7-15 working days after receiving the order. We will maintain close communication with you to ensure on-time delivery.

Contact us now to start your customized carbide chuck reamer journey, and let us drive your productivity and machining quality to new heights together!