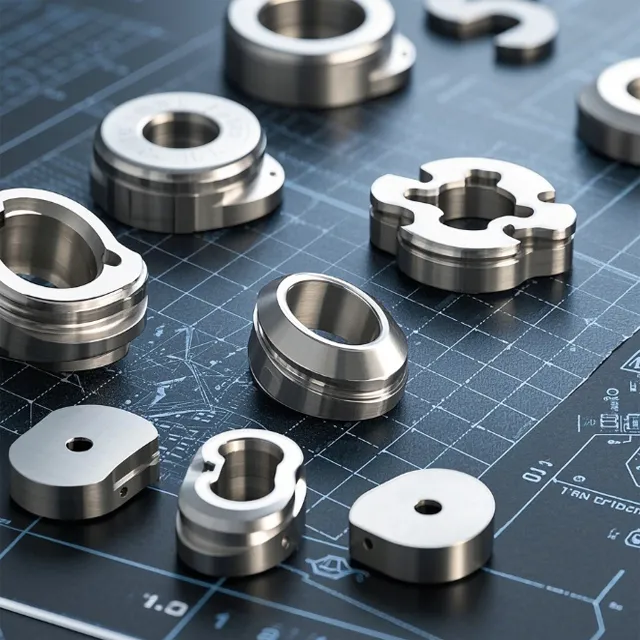

Custom CNC Part Machine Fabrication Aluminum Alloy Machining Service

Processing materials: Aluminum alloy (6061 – T6/7075 – T6/7000 series), Brass (H59/H62), Titanium alloy (Gr5/Ti6Al4V), etc.

Processing accuracy: 1. Conventional accuracy: ±0.01mm; 2. High – precision requirement: ±0.005mm (supported by CMM calibration)

Processing types: Turning, Milling, Drilling, Micro Machining, Complex surface machining (3D contour)

Surface treatment: Anodizing (for aluminum alloy, natural color/black/color available), Sandblasting (Ra 0.8 – 1.6μm), Mirror polishing (Ra ≤0.4μm), Electroplating (zinc/nickel/chrome), Powder coating (RAL color card available)

Application fields:

Automotive: Engine mounts, Sensor housings, Structural parts of new energy batteries

Aerospace: Aircraft frames, Hydraulic valve bodies

Consumer electronics: Drone housings, Radiators, Structural parts of smart wearables

Industrial equipment: Robot joints, Gearbox components

Description

Product Service Introduction

Core Advantages

Ultra – high – precision Machining:

The conventional accuracy reaches ±0.01mm, and for high – precision requirements, it can be increased to ±0.005mm. The coordinate measuring machine is used for full – process calibration to ensure the strict tolerance requirements of key components such as automotive sensor housings and drone frames.

Supports micro – machining (aperture ≥ 0.5mm) and thin – walled part machining (wall thickness ≥ 0.3mm), solving the technical difficulties of precision electronic components and aerospace parts.

Full Material Coverage and Process Innovation:

Mainly promotes the machining of aluminum alloy (6061 – T6/7075 – T6), and also takes into account the composite machining of multiple materials such as stainless steel, brass, and titanium alloy, adapting to the needs of lightweight and high – strength.

Innovative deep – hole machining technology (depth ≤ 50mm), combined with diamond – coated tools, improves the machining efficiency of hard materials by 30%.

Flexibility and Cost Optimization:

Minimum order quantity is 1 piece + free rework samples. Supports rapid prototyping within 3 – 7 days, reducing customers’ trial – and – error costs.

Provides free DFM (Design for Manufacturability) analysis, optimizes the part structure, and reduces material waste and machining time.

Service Scope

Processing Types: Covers turning, milling, drilling, and complex surface machining (3D contour), meeting diverse needs such as automotive drive shafts and industrial robot joints.

Surface Treatment:

Anodizing (12 RAL color cards available for selection), mirror polishing (Ra≤0.4μm), enhancing the appearance texture of consumer electronic products.

Sandblasting, electroplating (zinc/nickel/chrome) processes, enhancing the corrosion resistance and wear resistance of automotive parts.

Customized Value – added Services: LOGO laser engraving, non – standard size design, and phased delivery of bulk orders.

Technical Capabilities and Quality Control System

Intelligent Machining Equipment:

5 – axis CNC machine tool + 24,000 RPM high – speed spindle, achieving a surface accuracy of 0.02mm.

Equipped with an automatic tool – changing system (30 + tool magazine), reducing the tool – changing downtime by 50%.

Inspection Guarantee:

Coordinate measuring machine (accuracy ±0.002mm) + surface roughness tester for double – quality inspection, meeting the IATF 16949 automotive industry standard.

Full – process traceability system, with each part accompanied by an inspection report and material certification.

Industry Application Cases

New Energy Vehicles: Lightweight battery trays (weight reduction of 20%), motor housings (thermal conductivity increased by 35%).

Consumer Electronics: Structural parts of smart watches (tolerance ±0.01mm), heat dissipation modules of AR/VR devices.

Industrial Automation: High – precision harmonic reducer components (service life extended by 2 times), hydraulic valve bodies (pressure – resistant up to 100MPa).

Marketing Guidance Words

“Make precision manufacturing your competitive advantage!”

✅ Limited – time Offer: Upload the drawing and enjoy a 10% discount on the first order. Free upgrade to expedited logistics for bulk orders!

✅ Quality Promise: Respond to quality issues within 48 hours. Pay 0.1% of the contract amount per day for overdue delivery!

✅ Technical Empowerment: The engineer team provides one – on – one optimization solutions to help you reduce the comprehensive cost by 15%!

Take Action Now:

📞 24 – hour Hotline: +86 – 18150097490

📧 Technical Consultation: charlie@plasticmetalparts.com

🌐 Online Quotation: https://www.xmgoldcattle.com/

“From prototype to mass production, what we offer is not just parts – but the core support for the success of your products!”