Description

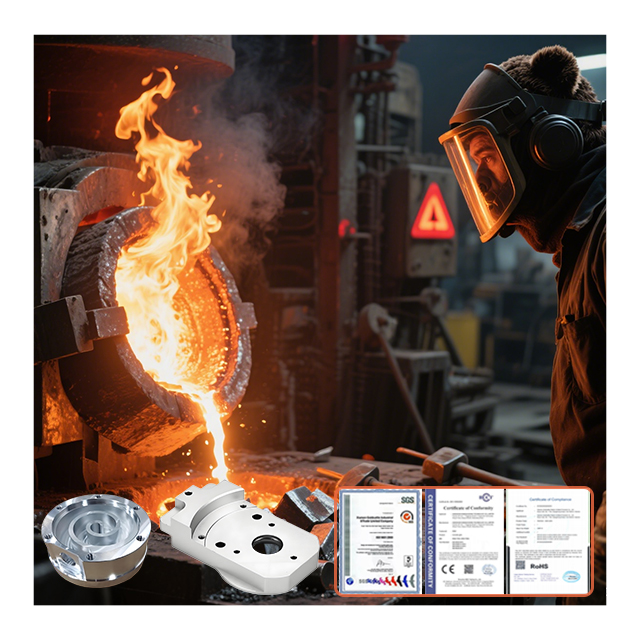

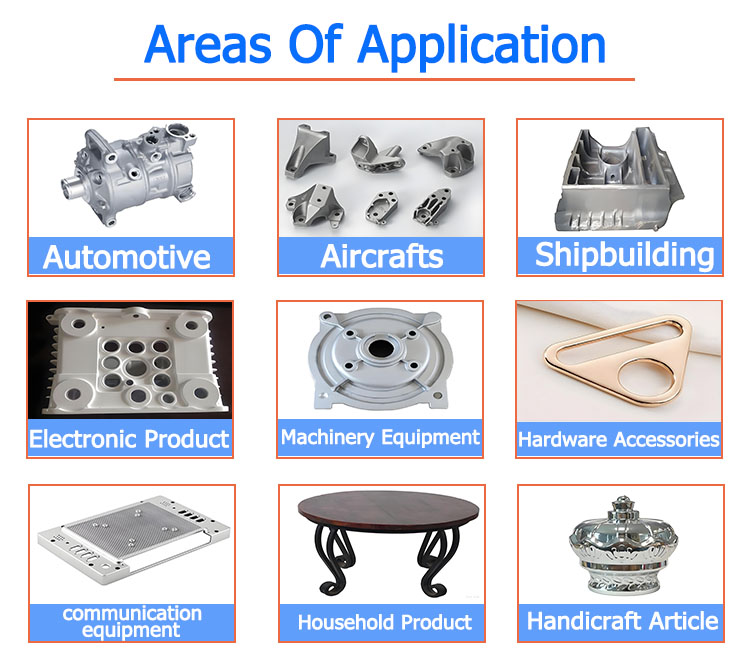

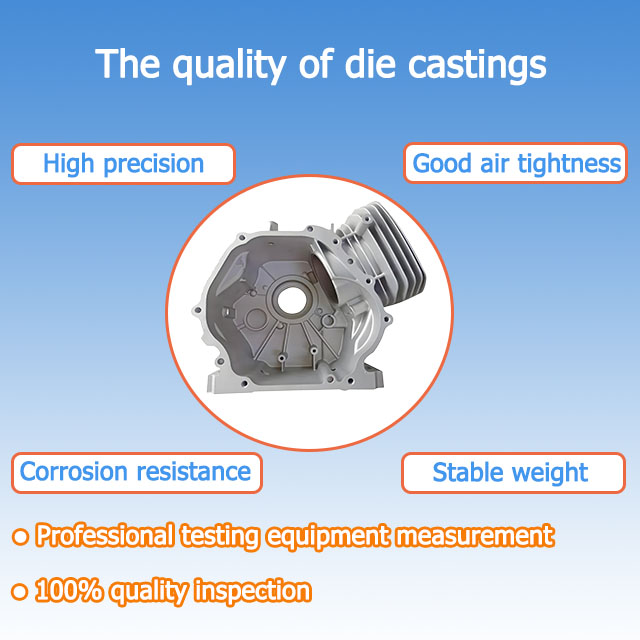

Our Custom Vacuum Investment Casting Parts utilize lost wax casting technology to achieve high-precision forming of metal materials such as iron, steel, and aluminum alloys, with tolerances controlled within 0.01-0.05mm. This meets the rigorous requirements of high-end fields like aerospace, automotive, and electronics. The products feature excellent airtightness, corrosion resistance, and stable mechanical properties. Surfaces can be customized through polishing, electroplating, anodizing, and other processes, suitable for diverse applications including lighting, medical devices, and industrial equipment.

- Vacuum Investment Casting Technology: Eliminates casting defects via the lost wax method, ensuring dimensional accuracy and surface finish, especially for mass production of complex structural parts.

- Full-process Quality Control: Equipped with professional equipment like CMM coordinate measuring machines, implementing 100% factory inspection to comply with ISO 9001 and RoHS certification standards.

- Material Flexibility: Supports processing of stainless steel, aluminum alloys, zinc alloys, magnesium alloys, and other materials to meet performance needs across industries.

As a professional manufacturer with 25 years of experience, we offer:

- Advanced Production Capacity: Equipped with cold chamber die-casting machines, vacuum die-casting machines, etc., with a monthly capacity of 1 million pieces and sample delivery within 7 days.

- Customized Services: Support ODM/OEM development with no MOQ required. We can design based on customer drawings (JPEG/PDF/DWG, etc.) or reverse-engineer from samples.

- Global Delivery Capability: Provide sea, air, and express logistics (DHL/UPS, etc.) with FOB Xiamen port, supporting payment methods like T/T and L/C.

Products are widely used in automotive parts, aerospace components, electronic communication equipment, home appliances, and other fields. Customer feedback: “Highly professional engineering team; parts precision exceeds expectations—our top choice for long-term cooperation.”—Backed by 5-star ratings from 200+ global clients.

For custom solutions or sample testing, please provide drawings, material requirements, and quantity needs. We will respond to your inquiry within 24 hours.