Description

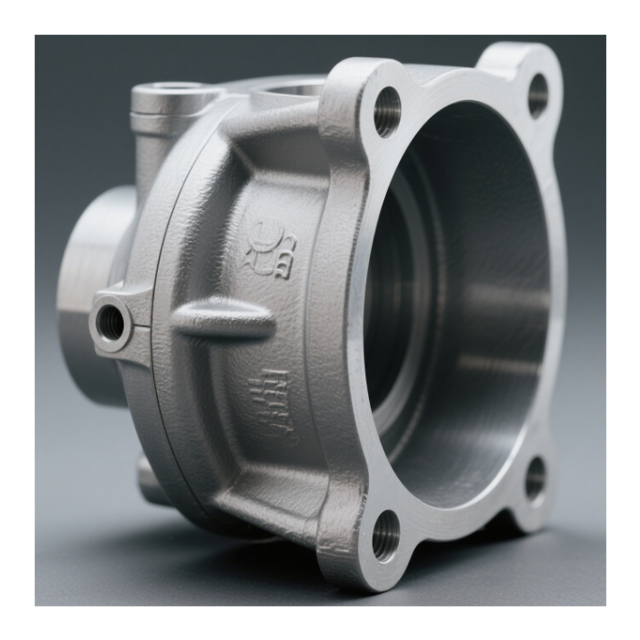

🚀 Custom – made Die – cast Parts for Water Pump Housing as Needed

Industrial – grade Durability・Full – process Customization・Fast Delivery

🔥 Why Choose Our Customization Service?

🔧 Five Core Customization Advantages

Optional Materials

Support aluminum alloy grades such as ADC12/A356/6061

Match corrosion – resistance/high – strength/easy – to – machine properties as needed

Free – form Structure

Complex flow channels/thin – wall/irregular structures can all be achieved

Minimum wall thickness of 0.5mm to meet high – precision fluid design

Custom Surface Treatment

Anodizing (wear – resistant)/Electrophoretic spraying (corrosion – resistant)/Sandblasting (primer)

Both appearance and functional coatings are available

Rapid Prototyping

Complete mold design + first – piece prototyping in 7 – 15 days

3D modeling to assist in confirming structural details

Scale – adaptable

Minimum order quantity for small – batch production is 100 pieces, stable production capacity for medium and large batches

Mold life of over 500,000 times, controllable cost for long – term cooperation

🛠️ Customization Process・Three Steps to Complete

✅ Transparent Exclusive Solutions

Demand Communication

Provide drawings/parameters/application scenarios

One – on – one engineer connection, feedback on feasible solutions within 24 hours

Prototype Confirmation

3D – printed hand – board pre – verification (optional)

First – piece coordinate measurement, provide dimensional/performance inspection reports

Mass Production and Delivery

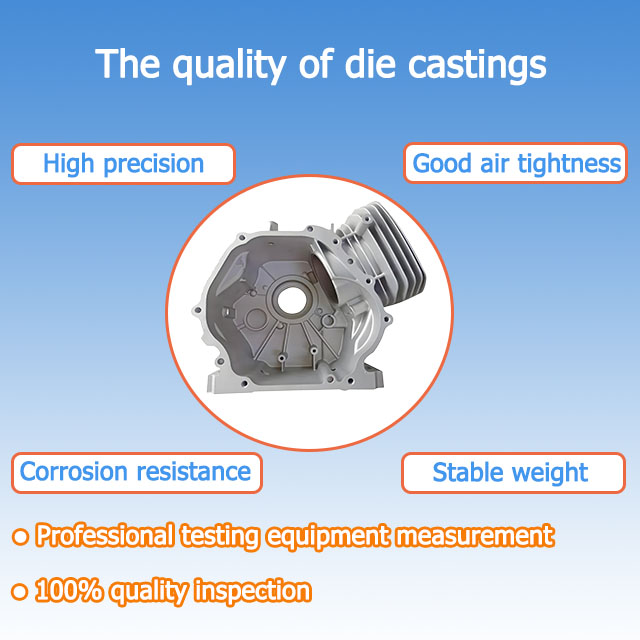

Full – process ISO 9001 quality control, yield rate ≥ 98%

Anti – collision packaging, support global air/sea transportation (72 – hour emergency order channel)

📊 Quick Overview of Core Performance Parameters

Item

Standard Configuration

Customization Range

Material

ADC12 (default)

A356/6061/Customer – specified alloy

Dimensional Accuracy

CT6 – 8 level (±0.1 – 0.3mm)

High – precision mold can reach ±0.05mm

Surface Roughness

Ra 4 – 8μm (as – cast state)

Ra ≤ 1.6μm after machining

Tensile Strength

≥220MPa (ADC12)

200 – 290MPa (different treatments)

Temperature Resistance Range

-40℃~150℃ (conventional)

Special coating can reach over 300℃

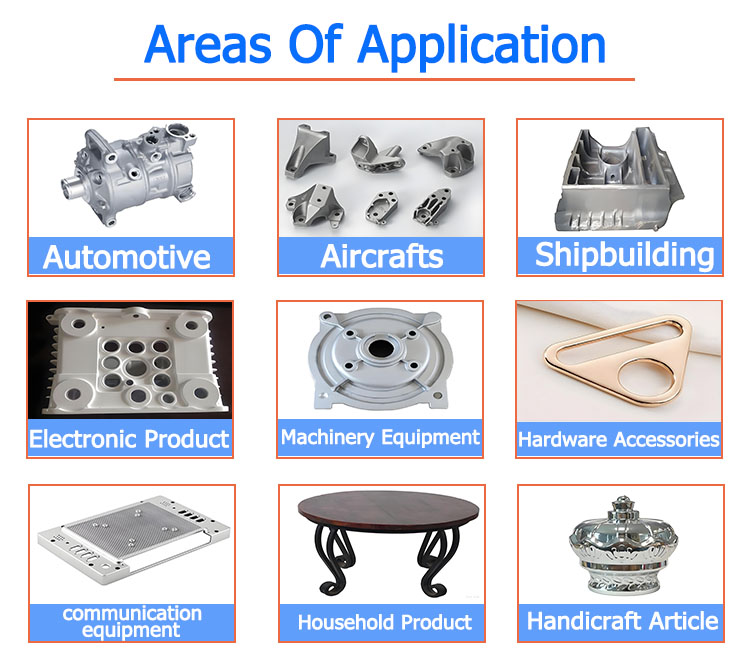

🌍 Applicable Scenarios・Covering All Industries

⚡ Industrial – grade Durability Adaptation

Water Pump Industry: Centrifugal pump/sewage pump/circulation pump housing

Machinery Manufacturing: Hydraulic valve block housing/compressor components

Environmental Protection Equipment: Filter housing of water treatment equipment

New Energy: Waterproof housing for charging piles/structural parts of energy storage equipment

💎 Service Guarantee・Peace – of – mind Customization

✨ Three Promises for Protection

Technical Support: Free DFM manufacturability analysis, reducing 30% of material costs

Quality Traceability: Each product is attached with a unique number, provide spectral/metallographic inspection reports

Worry – free After – sales Service: Respond within 72 hours for non – customized parameter issues, free return and exchange

📢 Customize Now・Start Your Exclusive Service