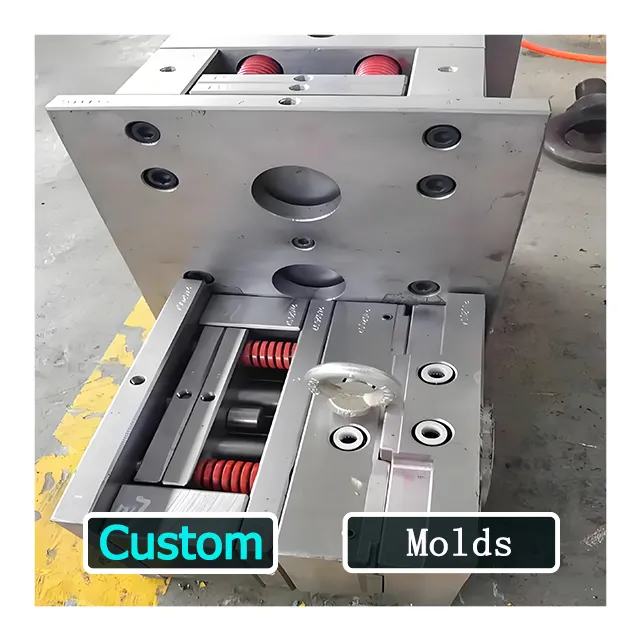

Custom Processing Furniture ABS Shell Cover Plastic Injection Mould

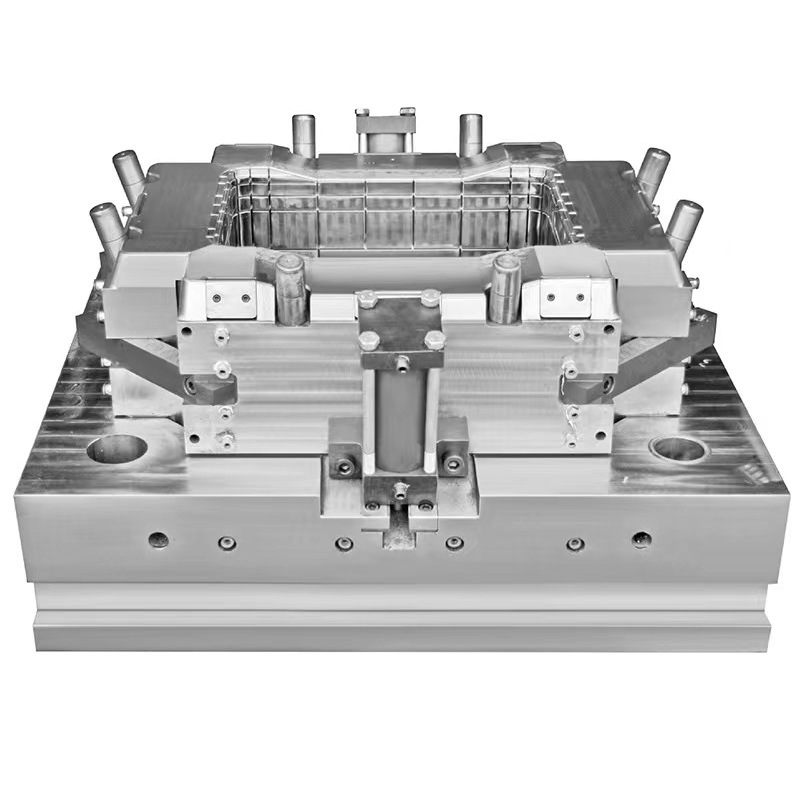

Product Name: Custom – processed Furniture ABS Shell Plastic Injection Mold

Mold Material: Commonly used P20/H13 mold steel

Product Material: ABS plastic

Mold Size: Approximately 500×400×300 mm (Can be customized according to product size)

Number of Cavities: 1 – 8 cavities (Supports single – cavity and multi – cavity designs)

Processing Precision: Dimensional tolerance range of ±0.03 – 0.05 mm

Single Injection Cycle: Approximately 10 – 30 seconds (Depending on product structure and process)

Service Life: 100,000 – 500,000 injection cycles

ABS Injection Temperature: 210℃ – 260℃

Finished Product Wall Thickness: 1.2 – 3.5 mm (According to design requirements)

Mold Weight: Approximately 50 – 300 kg (Determined according to mold structure and size)

Surface Treatment: Electroplating or polishing, surface roughness Ra 0.8 – 1.6 μm

Description

Custom ABS Furniture Shell Injection Molds

Bro, let me tell you – these ABS molds are GAME CHANGERS for furniture manufacturing! We’re talking precision, durability, and cost savings that’ll make your accountant do a happy dance.

Our ABS Furniture Shells

Premium ABS Material

Dude, this material is LEGIT! ABS (Acrylonitrile Butadiene Styrene) is like the Swiss Army knife of plastics – tough, flexible, and looks amazing.

Here’s the breakdown: Acrylonitrile gives chemical resistance, Butadiene adds impact strength (these things can take a beating!), and Styrene provides that glossy finish we all love.

Material Properties:

- ✓ Tensile Strength: 45-50 MPa (that’s STRONG)

- ✓ Impact Resistance: 22 kJ/m² (drop test? No problem!)

- ✓ Heat Resistance: Up to 87°C (can handle summer heat)

- ✓ Surface Finish: Class A (looks like a million bucks)

Advanced Injection Molding Process

Let me walk you through how we make these bad boys. It’s not magic, but it’s pretty close!

Process Steps:

- Drying: ABS pellets get baked at 80°C for 4 hours (no moisture allowed!)

- Melting: Heated to 220-260°C in the barrel (liquid gold, basically)

- Injection: Shot into mold at 80-120 MPa pressure (like a plastic cannon!)

- Cooling: Mold stays at 40-80°C for 20-60 seconds (patience is key)

- Ejection: Perfect part pops out, ready for action!

Pro tip: The temperature control is CRUCIAL. Too hot and you get burnt plastic, too cold and you get defects. We’ve nailed this balance!

Technical Specs & Testing Data

Mold Specifications

Test Results (For reference only)

| Test Item | Standard | Result | Unit |

|---|---|---|---|

| Tensile Strength | ISO 527-2 | 48.5 | MPa |

| Flexural Modulus | ISO 178 | 2700 | MPa |

| Izod Impact Strength | ISO 180 | 22.3 | kJ/m² |

| Heat Deflection Temp | ISO 75-2 | 87 | °C |

| Vicat Softening Temp | ISO 306 | 105 | °C |

| Melt Flow Rate | ISO 1133 | 12 | g/10min |

Compliance & Standards

We Meet Global Standards

Look, we don’t mess around when it comes to quality. Our molds and products meet all the big boy standards – no shortcuts here!

ISO Standards

- ISO 19062-2:2019 – ABS materials

- ISO 20457 – Tolerance standards

- ISO 294-4 – Molding shrinkage

- ISO 9001:2015 – Quality management

ASTM Standards

- ASTM D4673 – ABS classification

- ASTM D638 – Tensile properties

- ASTM D256 – Impact resistance

- ASTM D648 – Heat deflection

Additional Certifications:

REACH Compliant

UL 94 HB Rated

FDA Food Contact

7-Step Customization Process

Design Analysis

We analyze your design and give HONEST feedback – no sugarcoating!

DFM Report

Detailed mold design for manufacturability – we catch issues BEFORE they happen

Mold Design

3D modeling with simulation – we test it digitally first, saving you time and money

Mold Making

CNC machining with precision tools – these molds are built to LAST

Trial Run

Sample production with full inspection – we get it right before mass production

Mass Production

Full-scale manufacturing with quality control – consistent parts every time

Delivery & Support

On-time delivery with ongoing support – we’re here for you AFTER the sale

Typical Lead Time: 4-8 Weeks

Need it faster? We offer expedited services for those “oh no, we need this yesterday” situations!

What Our Clients Say

“These ABS molds are INSANE! We’ve been using them for 2 years now and they’re still going strong. The precision is mind-blowing – no more fitting issues!”

“The cost savings were huge! We reduced our production costs by 22% compared to our previous supplier. And the quality? Even better than before!”

“Their technical support is top-notch. When we had a minor issue, they responded within 30 minutes and had it fixed by the next day. Total lifesavers!”

Ready to Upgrade Your Furniture Manufacturing?

Our custom ABS injection molds will transform your production process – better quality, lower costs, faster delivery.

+86-18150097490

charlie@plasticmetalparts.com 🌐

www.xmgoldcattle.com