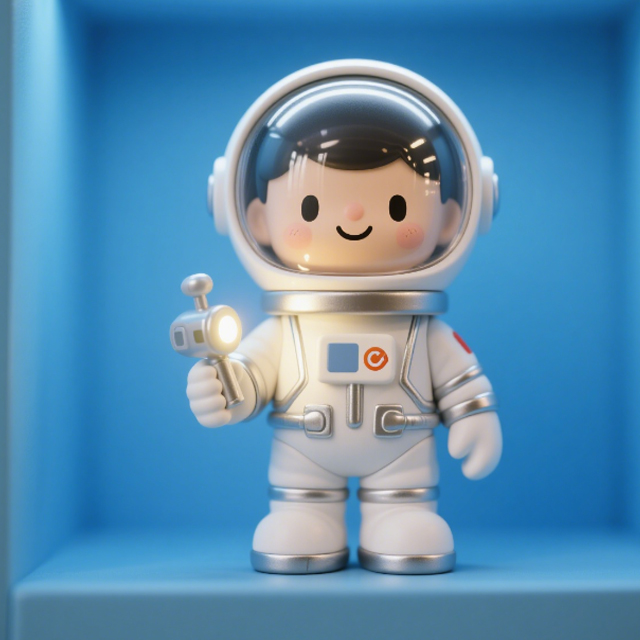

Custom PVC Injection Molded Figurines

| Parameter | Capability |

|---|---|

| Material | Eco-PVC (Phthalate-Free • FDA Compliant) |

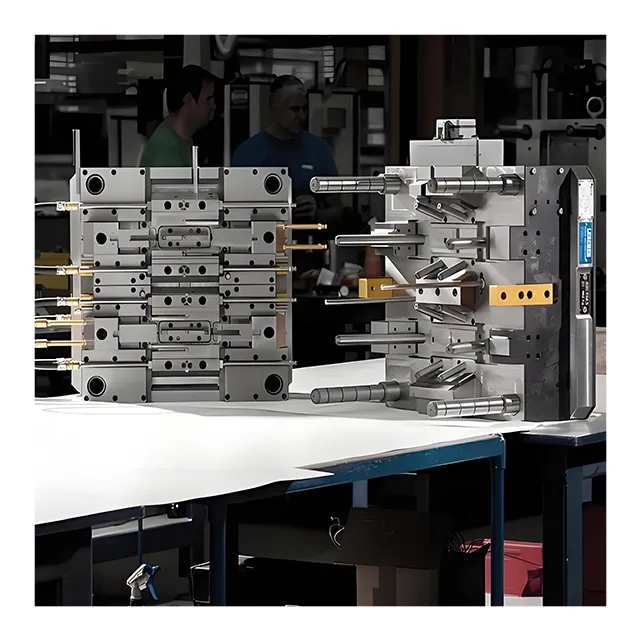

| Mold Type | Aluminum (Prototype) • Steel (Production) |

| Color Application | Masterbatch • Pantone Matching • Spray Painting |

| Max. Height | 300mm (Single-Piece) • 1200mm (Multi-Part) |

| Detail Resolution | 0.15mm Fine Features |

| Surface Finish | Glossy • Matte • Velvet Touch • Gradient |

| Production Capacity | 500,000+ Units/Month |

| Lead Time | 10 Days (Sampling) • 25 Days (Mass Production) |

| Certifications | EN71 • ASTM F963 • REACH • CPSIA |

| MOQ | 100 Pieces (Custom Designs Welcome) |

Description

Specializing in high-detail PVC injection figurines, we transform character designs into vibrant collectibles and promotional products through precision tooling and advanced coloring technologies. Our vertically integrated manufacturing combines Haitian Electric Injection Machines (80-1000T) with in-house mold fabrication, ensuring consistent quality from prototype to million-unit production runs for toy brands, movie merchandisers, and marketing agencies.

Material Innovation:

• Child-Safe Formulations: Proprietary Eco-PVC blend passes CPSIA lead testing and EU Toy Directive EN71-3 migration limits

• Special Effects: Glow-in-dark (8+ hour persistence), thermochromic (color-change at 31°C), and pearlescent finishes

• Durability Enhancements: Impact-modified recipes withstand 1.5m drop tests (ASTM D5276)

Precision Manufacturing Process:

-

Digital Sculpting: 3D scan conversion with 0.05mm resolution preservation

-

Tooling: Multi-slide steel molds with conformal cooling (cycle time reduction 30%)

-

Injection: Scientific molding with cavity pressure monitoring

-

Post-Processing: Robotic trimming • Ultrasonic welding • Automated painting

Customization Capabilities:

-

Articulation Engineering: Ball-joints • Snap-fit connectors • Spinable bases

-

Accessory Integration: Overmolded clothing • Magnetic attachments • Sound modules

-

Packaging Solutions: Blister cards • Window boxes • Collector tins with foam inserts

Industry Applications:

✓ Entertainment: Limited-edition anime collectibles with certificate of authenticity

✓ Promotional: Brand mascots with QR code integration

✓ Education: Anatomical models with removable organs

✓ Gaming: Tabletop miniatures at 28mm/32mm scale

Quality Assurance Protocol:

-

Material batch testing (GC-MS for phthalates)

-

Pre-production first article inspection (FAIR)

-

Production monitoring (SPC control charts)

-

Random drop testing (ISTA 1A standard)

Technical Advantages:

• Undercut resolution without parting lines (collapsible core tech)

• Seamless multi-material bonding (PVC/TPE/ABS)

• Micro-detail replication (fingerprints, fabric textures)

• UV-resistant pigments (5+ years fade guarantee)

Value-Added Services:

-

Free 3D rendering of your design concept

-

Mold flow analysis to prevent sink marks

-

Small-batch sampling (10+ units)

-

Global compliance documentation support

Describe your figurine concept, target audience, and quantity needs below – our toy production specialists will provide solutions within 12 hours!