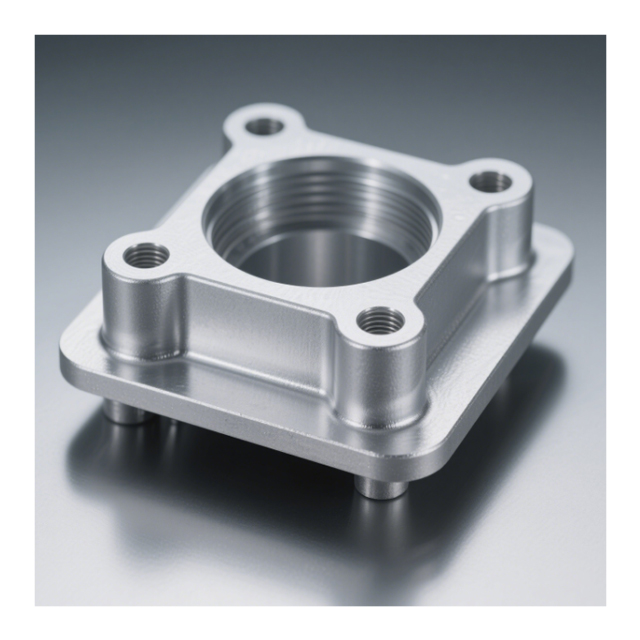

Customized aerospace aluminum alloy die – castings

Processing materials: Aviation – grade aluminum alloys are used (such as A380, A356, ZL104, etc.).

Characteristics: High corrosion resistance, adaptable to complex aviation environments such as high humidity and salt spray.

Processes: High – pressure die – casting (with pressure up to over 1000 bar) or vacuum die – casting processes are adopted.

Accuracy: The tolerance grade can reach CT6 – CT8 (GB/T 6414), and the surface roughness is Ra≤3.2μm.

Customization: Full – process customization services from drawing design, mold development to mass production are supported.

Standards: Comply with AMS 2771 (heat treatment of aluminum alloys), ASTM B179 (die – casting standards) and AS9100 aviation quality management system.

Description

1. Processable Materials (Aerospace-Grade Alloys)

|

Material Type

|

Typical Grades

|

Core Properties

|

|

Aluminum Alloy

|

7075-T6, 6061-T6

|

Tensile Strength ≥572MPa, Density 2.8g/cm³, Heat Resistance ≤200℃

|

|

Titanium Alloy

|

Ti-6Al-4V (TC4)

|

Tensile Strength ≥900MPa, Density 4.43g/cm³, Heat Resistance ≤500℃

|

|

Magnesium Alloy

|

AZ91D

|

Tensile Strength ≥240MPa, Density 1.8g/cm³, Optimal for Lightweight Design

|

|

High-Temperature Alloy

|

Inconel 718

|

Tensile Strength ≥1220MPa, Heat Resistance ≤700℃, Excellent Fatigue Resistance

|

2. Dimensional Processing Capabilities

- Size Range: Maximum 1000×800×500mm (L×W×H)

- Minimum Wall Thickness: 0.5mm (complex structures) / 1.0mm (regular parts)

- Dimensional Tolerance: GB/T 6414 CT4 Grade (±0.15mm/100mm)

- Surface Roughness: Ra≤1.6μm (mold surface) / Ra≤0.8μm (polished surface)

- Weight Range: 0.1kg–50kg (per part)

3. Surface Treatment Processes (Aerospace Standards)

|

Process

|

Performance Indicators

|

Application Scenarios

|

|

Anodizing

|

Oxide film thickness 10–25μm, Salt spray test ≥500h

|

Corrosion protection & insulation for aluminum parts

|

|

Electroless Nickel Plating

|

Coating hardness HV 500–600, Thickness 5–15μm

|

Wear resistance enhancement for titanium parts

|

|

Passivation Treatment

|

Blue spot test corrosion-free, Film thickness 2–5μm

|

Oxidation resistance for high-temperature alloys

|

|

Conductive Anodizing

|

Surface resistance ≤0.1Ω, Film thickness 0.3–0.5μm

|

Electromagnetic shielding components

|

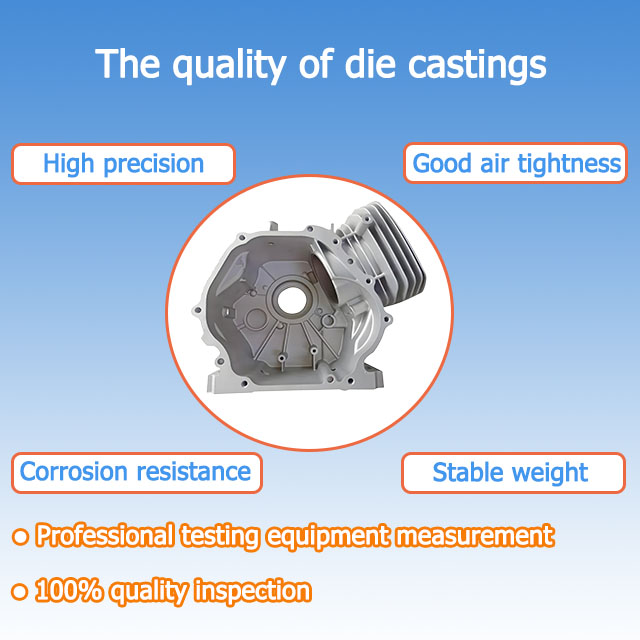

4. Core Characteristics (Data-Driven Advantages)

- High Precision: CMM inspection accuracy ±0.005mm, First-piece full inspection rate 100%

- Low Defect Rate: X-ray flaw detection defect rate ≤0.1%, Air tightness test 0.6MPa leak-free

- Long Service Life: Mold life ≥50,000 cycles (titanium parts), Fatigue test cycles ≥10⁶ times

- Lightweight Design: Specific strength (strength/density) 300%+ higher than traditional steel

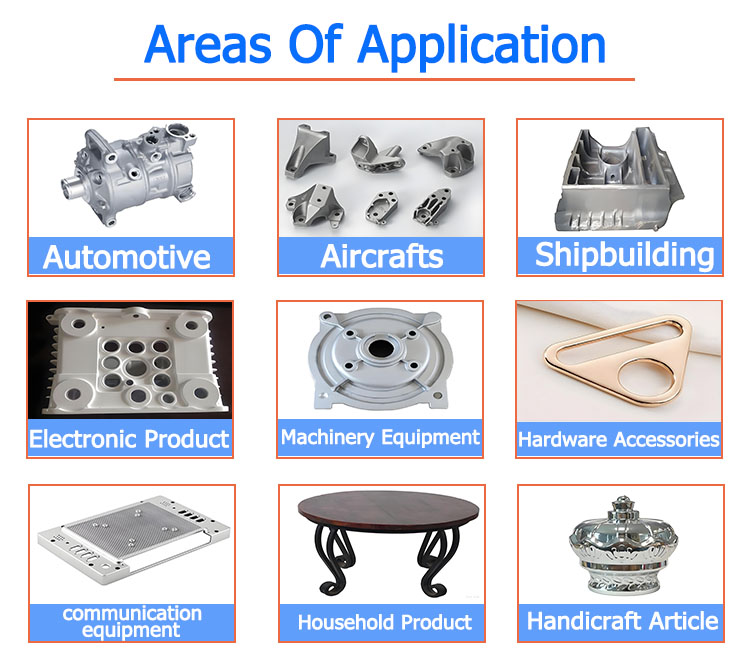

5. Application Areas (Aerospace Adaptation)

- Engine Systems: Compressor blades, fuel pump housings (high pressure resistance 20MPa, heat resistance 650℃)

- Structural Components: Wing ribs, fuselage frames (weight reduction 15%–30%, compliant with AS9100D)

- Landing Gear Systems: Joint connectors, brackets (tensile strength ≥800MPa, passed aerospace stress tests)

- Avionics Equipment: Enclosures & mounting frames (electromagnetic shielding effectiveness ≥60dB, surface conductivity ≥10⁶S/m)

Contact now for exclusive quotes including material solutions + inspection reports + aerospace certifications!