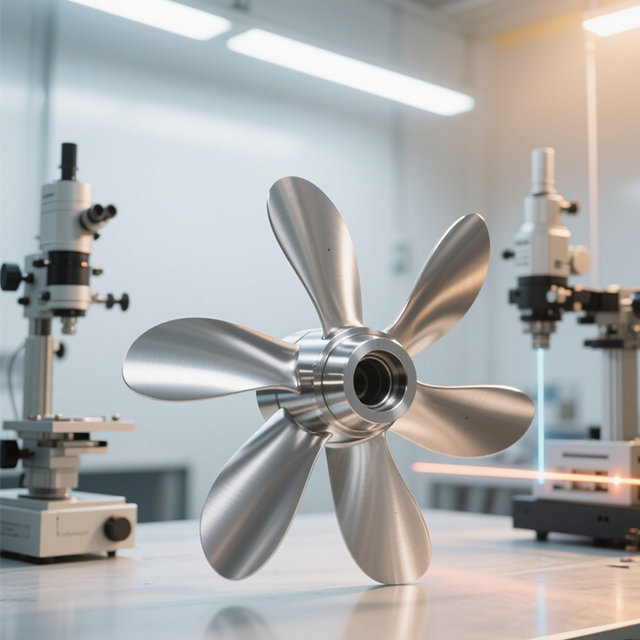

High – precision custom metal parts for aluminum products processing

|

Attribute

|

Details

|

|

Machining Types

|

CNC lathe, wire cutting, drilling, machining center, knurling, turning, parts processing, laser cutting, grinding, tapping, copper parts processing, waterjet cutting, milling, aluminum alloy processing, thermal cutting, electrical discharge machining, boring, planing, stainless steel parts processing, aluminum parts processing, turning, welding, CNC hardware milling, extrusion, sawing, punching, thread tapping

|

|

Machining Precision

|

±0.01mm

|

|

Processing Materials

|

Plastic, PVC, stainless steel, aluminum alloy, acrylic, copper, iron, PC, PU, ABS, PPS, brass, HDPE, POM, iron plate, carbon steel, bronze, stainless steel plate, red copper, aluminum, PEEK, aluminum profile, stainless steel, special steel, aluminum alloy, PP, PA (nylon), 40CrMo/304

|

|

Maximum Length

|

999

|

|

Tolerance

|

Customizable tolerance supported

|

|

Surface Roughness

|

Ra1 – Ra3.2

|

|

Sampling Cycle

|

7 days

|

|

Processing Cycle

|

15 days

|

|

Brand

|

Mingxiangxing (example, can be replaced)

|

|

Specification

|

CNC custom processing

|

Description

Product Details Marketing Article

In the booming modern manufacturing industry, the demand for high-precision custom metal parts is growing rapidly. We specialize in aluminum products processing, committed to providing you with outstanding high-precision custom metal parts to meet your diverse production needs.

I. High-Precision Machining, Excellent Quality

We adopt advanced CNC machining technology, operating through precise computer control of numerically controlled machine tools. This enables us to produce various aluminum products with extremely complex shapes and high-precision requirements. Whether it is fine hole machining or complex surface carving, we can achieve an ultra-high machining precision of ±0.01mm, ensuring that the dimensional accuracy and surface quality of the products meet or even exceed industry standards. Compared with traditional machining methods, CNC machining greatly reduces human errors, guaranteeing the high quality and stability of each custom part.

II. Aluminum Alloy Materials, Superior Performance

Aluminum alloy, as the main material for our processing, has many excellent characteristics. With a low density, only one-third of that of steel, the parts produced are lightweight, which gives significant advantages in fields with strict weight requirements such as aerospace and automotive manufacturing. It helps reduce the overall weight of products, improving transportation and usage efficiency. Meanwhile, aluminum alloy has good mechanical properties, with sufficient strength and stiffness to support the operation requirements of various products. The naturally formed oxide film on its surface endows the parts with excellent corrosion resistance, effectively extending the product’s service life and reducing maintenance costs. In addition, aluminum alloy has excellent thermal conductivity, well meeting the heat dissipation requirements of electronic devices and other products.

For example, 7075 aluminum alloy belongs to super duralumin and is widely used in high-end fields such as aerospace and precision equipment. It contains elements like zinc and magnesium. After heat treatment, it has extremely high strength, far superior to low-carbon steel. Its smaller grain size results in deeper drilling performance, higher tool wear resistance, and excellent thread rolling effects. 6061 aluminum alloy, on the other hand, has good formability, weldability, and machinability, as well as medium strength. It can still maintain good operability after annealing, making it suitable for general industrial manufacturing scenarios with high requirements for corrosion and oxidation resistance. 1060 pure aluminum plate, with an aluminum content as high as 99.6%, has good elongation and tensile strength, and its price advantage is obvious, satisfying conventional processing with no special requirements for aluminum plate performance.

III. Wide Applications, Meeting Diverse Needs

Our high-precision custom aluminum metal parts play a crucial role in multiple industries. In the aerospace field, they are used to manufacture aircraft frames, engine components, etc. Their high strength and lightweight characteristics ensure flight safety and fuel efficiency. In the automotive industry, they can be used to produce engine blocks, wheels, etc., enhancing the overall performance of vehicles. In the field of electronic devices, they are suitable for the casings and internal components of mobile phones, computers, etc., ensuring both the structural strength of the products and meeting the heat dissipation requirements. In the field of mechanical manufacturing, various high-precision mechanical parts can ensure the stable operation and high-precision operation of mechanical equipment.

IV. Customized Services, Intimate and Worry-Free

We deeply understand that each customer’s needs are unique. Therefore, from the product design stage, our professional team will communicate closely with you, deeply understand your specific needs and application scenarios, and provide you with professional advice and customized solutions. Whether it is single-sample production or large-scale batch production, we can efficiently complete the tasks with our advanced equipment and rich experience. We have more than 32 Japanese FANUC precision lathes and high-precision 4-axis and 5-axis machining groups, which can complete all machining processes of parts in a single clamping, meeting all requirements from rough machining to finishing, and achieving efficient and high-precision automated processing. At the same time, we can also cooperate with customers to conduct surface treatments such as oxidation and electroplating on CNC-machined parts, ensuring product quality and enhancing product added value.

From material selection to factory delivery, we have established a strict quality monitoring system. Equipped with a full set of testing equipment such as contour measuring instruments, coordinate measuring machines, two-dimensional measuring instruments, hardness testers, infrared automatic detection machines, and roughness testers, each batch of products undergoes three precision inspections to ensure that they can be delivered only after passing the inspection, giving you peace of mind. Moreover, we respond quickly, providing free samples within 2 days and delivering goods as fast as 5 days, fully meeting your urgent production needs.

Choosing our high-precision custom metal parts in aluminum products processing means choosing high quality, high efficiency, and high cost-effectiveness. We look forward to working with you to contribute to your projects and create more value.