Description

25-Year Precision Casting Expert · Stainless Steel Silica Sol Casting Customization — Micron-Level Precision, 1 Piece MOQ

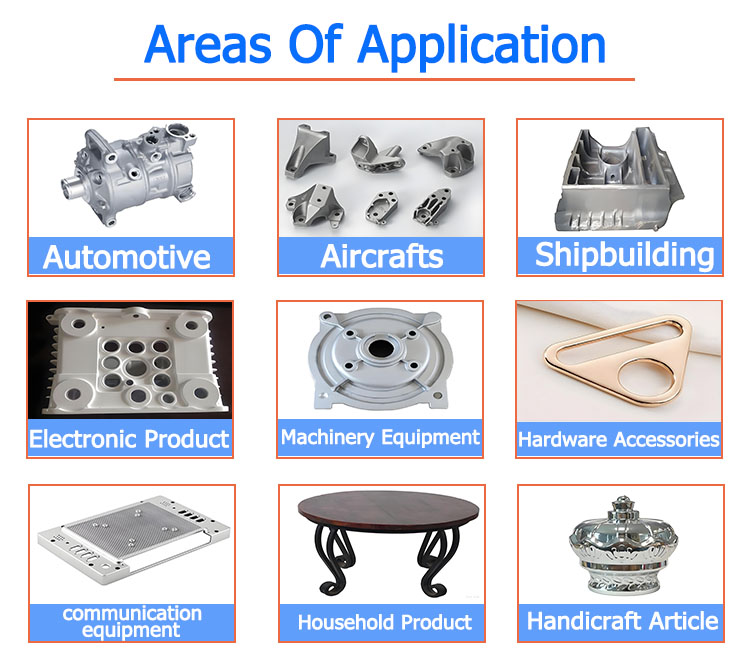

As a source factory specializing in silica sol casting (investment casting) for 25 years, we provide high-precision casting services for metal parts made of stainless steel, aluminum alloy, zinc alloy, and more. Equipped with advanced silica sol casting production lines and 300-ton die casting equipment, we control the entire process from mold development and casting production to surface treatment, offering flashless and low-machining precision casting solutions for industries like automotive, aerospace, and medical.

✅ Material Advantages: Specialize in stainless steel (304/316L) casting for high strength and corrosion resistance. Support customization of special materials like titanium alloy and magnesium alloy.

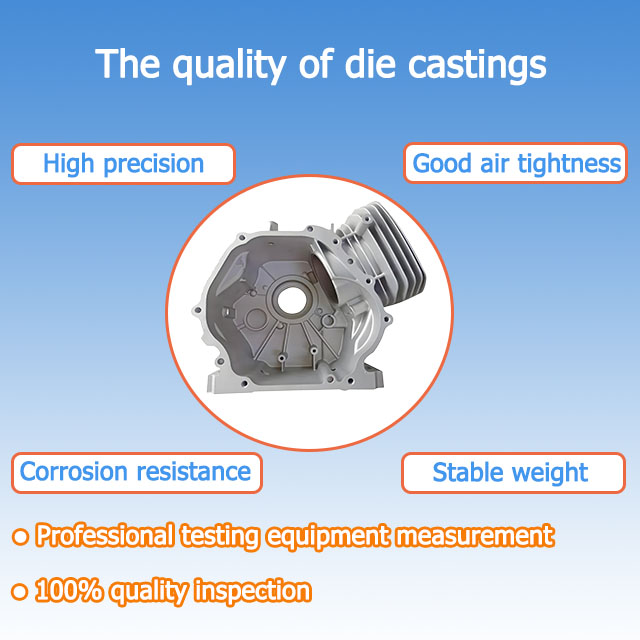

✅ Process Precision: Silica sol technology achieves ±0.005mm tolerance and surface roughness Ra≤1.6μm, enabling complex internal cavities and thin-walled structures in one step.

✅ Surface Treatments: 20+ options including polishing, electroplating, and anodizing to meet both aesthetic and functional requirements.

✅ Flexible Customization: 1 piece MOQ (no minimum order limit), drawing-based processing (supports DWG/STEP/IGS), and free mold design optimization.

✅ Quality Assurance: ISO 9001-certified factory with 100% full inspection (CMM measuring, fluorescent flaw detection, airtightness testing) to eliminate defects like porosity and shrinkage.

- Requirement Communication: 2-hour response to confirm materials, processes, and surface treatments.

- Rapid Prototyping: Samples delivered in 7 days with 3D printing pre-confirmation to reduce development risks.

- Bulk Production: Monthly capacity of 1,000,000 pieces; negotiable lead times for orders over 500 pieces.

- Global Logistics: FOB Xiamen port, supported by DHL/UPS/sea freight with 100% on-time delivery.

- After-Sales Support: 6-month quality guarantee with 24-hour response to issue resolution.

🔧 Advanced Equipment: German silica sol shell-making production lines improve casting dimensional accuracy by 30%.

💡 Technical Expertise: 15-person R&D team solves complex casting challenges (e.g., turbine blades, medical precision parts).

🌍 Global Service: 99% positive review rate, exporting to 20+ countries including the U.S., Canada, and the Netherlands.

🌱 Eco-Compliant: RoHS-certified processes with 95% recycling rate for casting waste.

Whether for single samples or mass production, click “Leave a Message for Inquiry” to upload drawings or share requirements and enjoy:

- Free Process Assessment: Engineering team provides feasibility solutions within 2 hours.

- Transparent Pricing: $0.55–$13.55 per piece (specification-dependent), no hidden fees.

- Fast Response: Dedicated customer service for 1-on-1 support with quote details within 1 hour.

Factory Information

- Company Name: Xiamen Goldcattle Plastic & Metal Products Co., Ltd. (9-year Alibaba verified supplier)

- Service Scope: One-stop customization for silica sol casting, investment casting, and pressure casting

- 24/7 Online Support: Click “Send Inquiry” to unlock high-precision casting solutions!

(Note: For silica sol casting process videos, inspection reports, or industry cases, message us to request materials!)