OEM Custom Injection Molding Plastic Parts

|

Attribute Category

|

Detailed Information

|

|

Product Type

|

OEM Custom Injection Molding Plastic Parts (Supporting thermoplastic/thermoset plastic & rubber molding)

|

|

Core Materials

|

Includes engineering plastics such as ABS, PC, PA (Nylon), POM, PP, PE, PMMA, LCP, etc., with support for special modified materials (e.g., conductive, flame-retardant, extreme temperature-resistant)

|

|

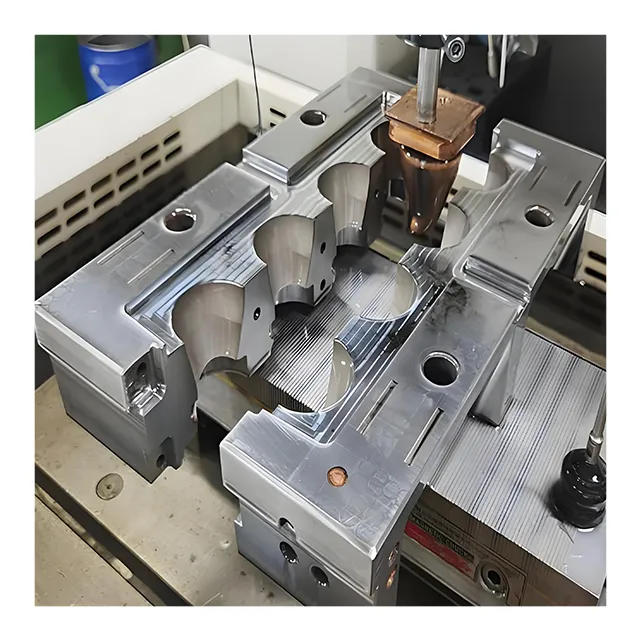

Molding Processes

|

High-precision injection molding (including multi-color injection, insert molding, micro-molding, gas-assisted molding, and other complex processes)

|

|

Technical Parameters

|

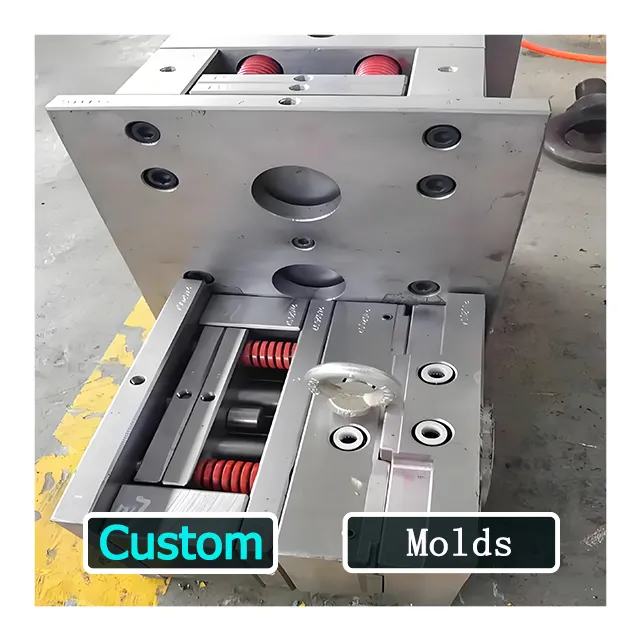

– Dimensional Accuracy: ±0.01mm (precision parts) / ±0.05mm (standard parts)- Surface Finishing: Full-process support for electroplating, painting, silk screening, laser engraving, etc.- Mold Life: Steel molds ≥500,000 cycles, aluminum molds ≥100,000 cycles (customized by material/structure)

|

|

Technical Advantages

|

– Independently developed DFM (Design for Manufacturability) system eliminates 98% of molding risks in the design stage- Equipped with 100-3000 ton servo injection molding machine fleet, supporting 0.1g micro-parts to 5kg large components- 100,000-class cleanroom (medical-grade production line), full-process MES system traceability

|

|

Customization Capability

|

Full-process OEM services from 3D modeling → mold design → sample validation → mass production optimization, supporting:• Drawing/sample/concept design conversion• Low-volume prototyping (50-500 pieces)• Multi-material composite molding (e.g., soft-over-hard rubber molding)

|

|

Application Fields

|

Consumer electronics (phone cases/charger housings), automotive (dashboard components/new energy battery parts), medical (medical consumables/diagnostic equipment parts), industrial equipment (gears/connectors), smart home, etc.

|

|

Quality Systems

|

IATF 16949 (automotive), ISO 13485 (medical) certified, supporting PPAP, PFMEA document delivery

|

|

Service Process

|

Requirement communication (24h response) → Solution design (including DFM report) → Mold manufacturing (45-90 days lead time) → First-article inspection (3D scanning) → Mass production → Global logistics (DHL/UPS/ocean freight)

|

Description

1. Engineering the Customization Boundary: End-to-End Capability from Concept to Part

As a 25-year veteran in OEM injection molding, we transcend traditional manufacturing limits with a three-in-one technical system integrating material R&D, structural optimization, and intelligent production. Whether it’s micron-level precision components for consumer electronics or high-strength structural parts for the automotive industry, we define customization standards through technical parameters, making every part a carrier of engineering solutions.

2. Full-Process Technical Empowerment: Redefining the OEM Injection Molding Value Chain

① Design Phase: DFM Frontloading to Eliminate Hidden Costs

- Proprietary AI-driven DFM analysis system generates a Manufacturability Analysis Report within 1 hour, accurately identifying over 20 design flaws such as uneven wall thickness, insufficient draft angles, and weld line risks

- Provides design optimization solutions: For example, upgrading to LCP material for thin-wall parts (wall thickness ≤0.8mm) while optimizing gate location to increase filling efficiency by 30%

- Enables complex structures: Two-color injection (e.g., integrated transparent + matte housing), insert molding (metal/PCB pre-embedded molding)

② Material Phase: Breaking Standard Limits, Customizing Performance Boundaries

- In-house material laboratory capable of special treatments for base resins, including glass fiber reinforcement (30%-60% filling), flame retardancy (UL94 V-0), and conductivity modification (surface resistivity ≤10³Ω)

- Develops tracking-resistant materials (CTI ≥600V) for new energy vehicle high-voltage components meeting UL746C requirements; customizes PP materials for medical consumables compliant with ISO 10993 biocompatibility testing

③ Manufacturing Phase: Smart Factory Achieves Precision-Efficiency Synergy

- 120+ servo injection molding machines (clamping force 100-3000 tons) equipped with Kistler pressure sensors for real-time cavity pressure monitoring, ensuring part weight variation <0.1% per mold

- Medical-grade clean production line: 100,000-class cleanroom + automatic dust removal system, supporting production of implantable medical device components (e.g., insulin pen housings)

- Intelligent mold management system: RFID chips embedded in each mold for automatic equipment parameter matching, reducing mold changeover time to 15 minutes

3. Multi-Dimensional Customization Scenarios: Adapting to Complex Industry Needs

|

Industry Scenario

|

Typical Custom Cases

|

|

Consumer Electronics

|

• Camera module bracket for smartphones (0.3mm wall thickness PC+ABS, accuracy ±0.02mm, UV coating required)• TWS earbud overmolding (silicone hardness customizable from 20-80 Shore A)

|

|

New Energy Automotive

|

• Battery pack seals (electrolyte-resistant EPDM, -40℃~120℃ cycle life ≥500 times)• Charging pile connectors (PA66+30%GF, CTI ≥600V, compliant with VW 80101)

|

|

Medical Devices

|

• Disposable syringe pistons (medical-grade PP, slip force ≤5N, ISO 11607 sterilization validated)• Endoscope components (PEI material, CT scan artifact-free design)

|

4. Why Choose Us? Three Core Advantages Building Customization Barriers

- Controlled-Risk Rapid Prototyping:

- 3D printing + aluminum prototype mold solution delivers first samples in 72 hours (40% shorter than conventional steel mold prototyping)

- First-article inspection using ZEISS CMM, providing CPK reports with 20+ critical dimensions

- Flexible Production Models:

- Low-volume production: 50-piece minimum order, supporting NPI (New Product Introduction) multi-version iteration

- Mass production: Up to 128-cavity molds, daily output exceeding 500,000 pieces (based on 50g parts)

- Global Compliance Support:

- Automotive: Provides PPAP-level documentation (including PSW, MSDS, full-dimension inspection reports)

- Medical: Supports CE MDR, FDA 510 (k) certification through production system document audit support

5. Start Your Customization Journey Now: 1-on-1 Dedicated Engineer Support

Whether you’re at the concept design stage, sample optimization, or cost-efficiency improvement for mature products, our engineering team offers:✅ Free DFM Manufacturability Analysis (including material recommendations & structural optimization)✅ Transparent Quotation System (mold cost breakdown + per-piece price composition)✅ Customized Project Management (dedicated PM with weekly production visualization reports)

Click the [Customize Now] button below to submit your 3D drawings or sample photos – we’ll respond with preliminary solutions within 4 hours. For urgent inquiries, fill out the right-side contact form (including project name, material requirements, and intended use) – technical experts will prioritize your request.

Choosing us means more than part manufacturing – it’s a partnership to solve engineering challenges, ensuring every customization need finds its optimal solution.