25-Year Casting Expert · Precision Lost Wax Casting Parts Customization — Start from Your Drawing, 1 Piece MOQ

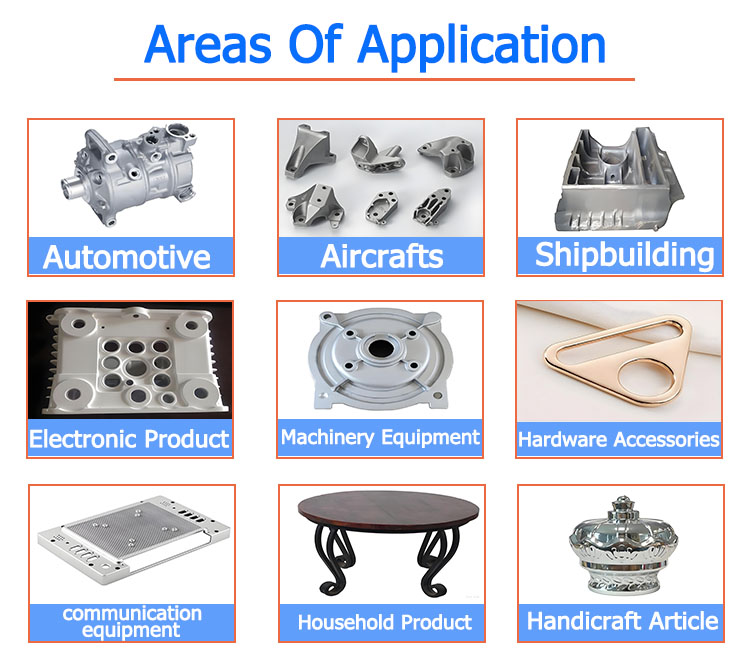

As a source factory with 25 years of metal casting experience, we specialize in lost wax casting and pressure casting to provide global customers with OEM/ODM customization services for metal parts (aluminum, iron, steel, magnesium alloy, zinc alloy, etc.). Equipped with advanced casting equipment (cold/hot chamber die casting machines, vacuum casting systems) and a 1,000㎡ standardized workshop, we control the entire process from drawing design to mold development, casting production, and surface treatment to meet high-precision requirements in automotive, aerospace, medical, and other industries.

✅ Material Flexibility: Stainless steel (304/316L), aluminum alloy (6061/7075), magnesium alloy, and other mainstream metals; special alloys can be customized.

✅ Complete Processes: Lost wax casting (investment casting) for complex structures in one step, pressure casting with ±0.005mm precision, and 20+ surface treatments (electroplating/anodizing/powder coating, etc.).

✅ Drawing Compatibility: Supports all formats (DWG/STEP/IGS/PDF, etc.). Professional engineers will complete feasibility assessment within 2 hours and provide free mold design optimization.

✅ Flexible MOQ: 1 piece minimum (no MOQ restrictions), samples delivered in 7 days, and monthly bulk production capacity up to 1,000,000 pieces.

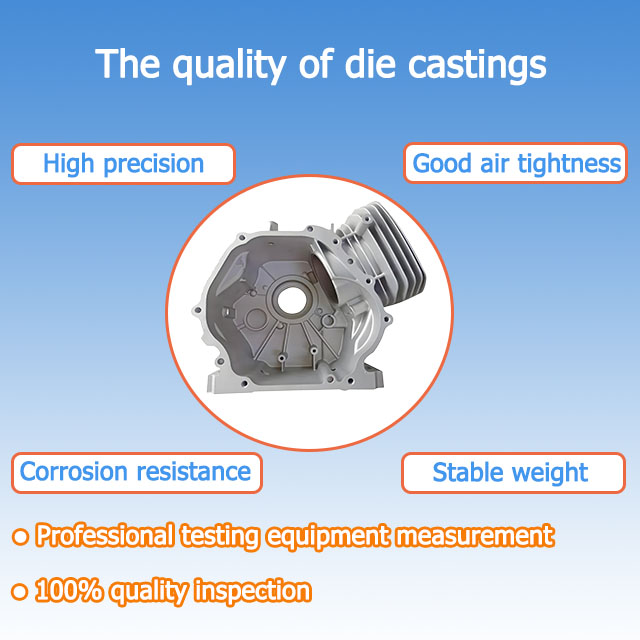

✅ Quality Assurance: ISO 9001-certified factory with 100% full inspection (CMM coordinate measuring/air tightness testing) to eliminate casting defects like porosity and cracks.

🔧 Advanced Equipment: Equipped with 300+ ton die casting machines and vacuum casting equipment, suitable for large parts (max. size 500mm) and micro-precision parts (min. hole diameter 0.5mm).

💡 Technical Support: A 15-person R&D team provides one-stop solutions from material selection to process optimization, reducing production costs by 30%.

🌍 Global Service: FOB Xiamen port, supported by DHL/UPS/sea freight, with a 100% on-time delivery rate. Served 300+ enterprises in Europe, America, and Southeast Asia.

🌱 Eco-Compliant: RoHS-certified products, raw materials from qualified suppliers, and casting processes meeting international environmental standards.

- Upload Drawings: Click “Leave a Message for Inquiry” to submit your design files (CAD/3D models/PDF, etc.) or mail samples to our factory.

- Detail Confirmation: 2-hour response time for 1-on-1 communication about materials, processes, surface treatments, etc., with detailed quotation provided.

- Rapid Production: Samples shipped within 7 days, bulk orders delivered within 30 days (negotiable lead times for orders over 500 pieces).

“The engineering team’s professionalism is outstanding. From drawing to sample took only 5 days, and the casting precision fully meets aerospace standards. We’ve established long-term cooperation!”

— R**o Platinum* (June 2024 Customer Review)

Whether for single-sample development or large-scale production, we offer transparent pricing ($0.55–$13.55 per piece, subject to specifications) and free mold design consultation! Click “Leave a Message for Inquiry” now, upload your drawings or share your requirements, and our dedicated team will connect with you within 1 hour to unlock your high-precision casting solution!

Factory Information

- Company Name: Xiamen Goldcattle Plastic & Metal Products Co., Ltd. (9-year Alibaba verified supplier)

- Service Scope: Custom metal casting parts, mold development, one-stop surface treatment services

- 24/7 Online Support: Click “Send Inquiry” for free technical consultation and process plans!

(Note: For factory equipment photos, inspection reports, or industry cases, message us to request materials!)