Description

25 – year – old 5 – axis CNC Processing Expert – Customized Precision Parts of Stainless Steel/Aluminum —— Micron – level Precision, Orders Accepted from 1 Piece

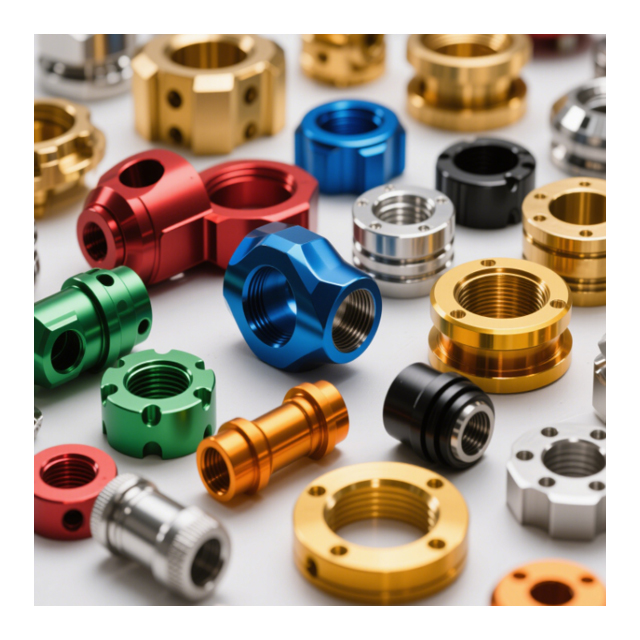

As a source factory with 25 years of experience in CNC processing, we are equipped with MAZAK 5 – axis CNC machine tools, 260 CNC lathes, and a fully – automated inspection center. We are dedicated to providing high – precision customized services for stainless – steel, aluminum – alloy, titanium – alloy, and engineering – plastic parts to customers worldwide. From complex surface machining to micro – part turning, we meet the needs of high – end fields such as aerospace and medical equipment with a tolerance of ±0.005mm and a surface roughness of Ra 0.1 – 3.2μm.

Full – process Customized Service – Redefining Precision Manufacturing

✅ Material Selection: Support over 50 materials including 304/316L stainless steel, 6061 – T6 aluminum alloy, titanium alloy TA1/GR5, PEEK engineering plastic, etc., and provide free material selection advice;

✅ Complete Processes: 5 – axis simultaneous machining (5 – Axis Machining) enables one – step forming of complex structures. Complemented by more than 20 processes such as milling, turning, drilling, wire – cutting (EDM), etc. We support processing according to drawings, sample replication, and reverse modeling;

✅ Surface Treatment: More than 10 processes are available (anodizing/electroplating/powder coating, etc.) to meet diverse needs such as anti – corrosion, wear – resistance, and aesthetics;

✅ Quick Response: Orders are accepted from 1 piece (no MOQ limit). Samples can be delivered in as fast as 1 day, and the monthly production capacity for batch orders reaches 1 million pieces;

✅ Quality Assurance: An ISO 9001 – certified factory, 100% full inspection (using CMM coordinate measuring machines and projectors) to reject dimensional deviations and surface defects.

Why Choose Us?

🔧 Leading Equipment: Imported Japanese MAZAK 5 – axis machine tools with a processing accuracy of ±0.005mm, and the processing efficiency of complex surfaces is increased by 50%;

💡 Professional Technology: A team of senior engineers provides full – process technical support such as drawing optimization and process planning, reducing development costs by 30%;

🌍 Global Service: FOB Xiamen Port, support DHL/UPS/ocean freight, 100% on – time delivery rate. We have served over 500 enterprises in Europe, America, and Southeast Asia;

📞 Worry – free Service: 24 – hour online response.

Customize Now – Get Your Exclusive Solution in 3 Steps

Upload Drawings: Click “Message for Consultation” to submit drawings in formats such as DWG/STEP/IGS, or mail samples to the factory;

Detail Confirmation: Engineers will complete the feasibility assessment within 2 hours and communicate with you one – on – one about materials, processes, and surface – treatment details;

Rapid Production: Samples will be shipped within 7 days, and batch orders will be delivered within 30 days (orders over 500 pieces enjoy an expedited channel).

Customer Reviews – Trustworthy

“The 5 – axis machining accuracy is astonishing. The samples fully meet the design expectations. The response speed and professionalism of the customer service far exceed those of peers!”

——R***o Platinum (Customer review in June 2024)

Contact Us for a Free Quote

Whether you need single – piece prototyping or large – scale mass production, click “Message for Consultation” to enjoy:

Free Process Evaluation: A professional team will optimize your drawings and provide the best processing solution;

Dedicated Customer Service: One – on – one follow – up throughout the process, providing real – time feedback on production progress.

Factory Information

Company Name: Xiamen Goldcattle Plastic & Hardware Products Co., Ltd.

Service Scope: One – stop service for 5 – axis CNC processing, mold development, and surface treatment

24 – hour Online Customer Service: Click “Send Inquiry” to unlock high – precision customized solutions!

(Note: If you need to view 5 – axis processing case videos, inspection reports, or actual equipment shots, please feel free to leave a message to request them!)