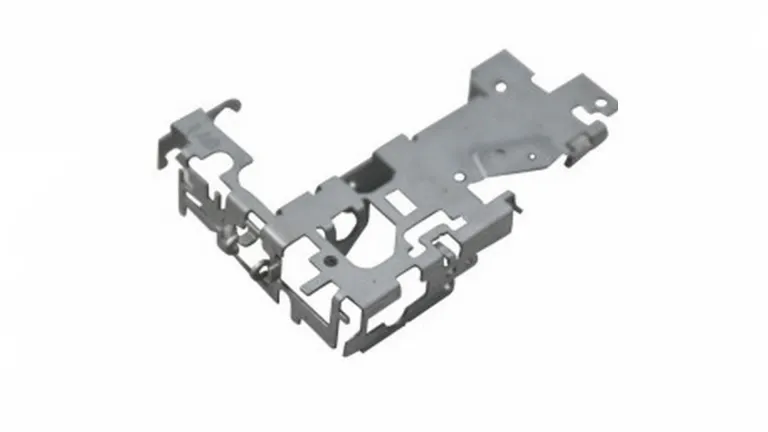

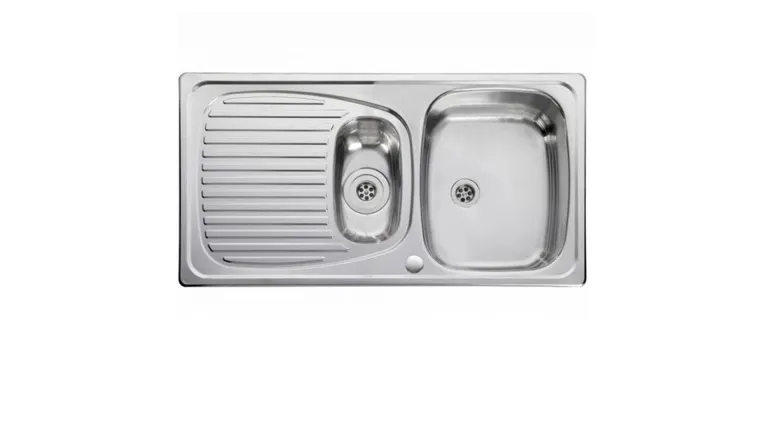

Industrial-grade custom sink stamping parts, durable and beautiful

Place of Origin : XiaMen, China

Brand Name : JSD

Model : MS-09

Process : Stamping, deep drawing, cutting, bending, welding

Material : Steel, stainless steel, aluminum, copper, etc.

Acceptance : OEM

Surface treatment : Galvanized, nickel-plated, tin-plated, chrome-plated, powder-coated, etc.

Application : Automotive, Machinery, Furniture, Electrical, etc.

Thickness : Customized service

Surface treatment : anodized, powder coated, painted, sandblasted, polished, etc.

Color : White, black, red, blue, silver, gold, multi-color, customer’s request, etc.

Quality control : 100% inspection

Description

Product Description

Our industrial-grade custom sink stampings are made of high-quality materials, combined with advanced design concepts and exquisite stamping technology to add durability and beauty to your products. These stampings are suitable for various industrial and commercial occasions to meet your customized needs for high-quality sink accessories.

Product Features

1. Material: Use durable and corrosion-resistant materials such as stainless steel, aluminum, etc. to ensure the long-term use of the product.

2. Design: Provide personalized design solutions according to your needs, including size, shape, hole position, etc.

3. Durability: After rigorous testing, ensure that the product maintains stability and durability in various usage environments.

4. Aesthetics: Adopt exquisite appearance design to enhance the overall image of the product.

5. Customization service: Provide customized service to meet your special needs.

Application scenarios

●Industrial occasions: sink systems suitable for industrial occasions such as factories, warehouses, workshops, etc.

●Commercial occasions: sink systems suitable for commercial occasions such as restaurants, hotels, shopping malls, etc.

●Home occasions: sink systems suitable for home kitchens, bathrooms, etc.

Customization Process

1. Demand Communication: Discuss project requirements with customers in detail, including materials, size, functions, etc.

2. Design Review: Design or optimize products according to customer requirements.

3. Sample Production: Make samples for customer verification and testing.

4. Mass Production: After the samples are confirmed to be correct, enter the mass production stage.

5. Quality Inspection: Carry out strict quality inspection during and after production.

6. Packaging and Delivery: Use safe packaging to ensure the safety of products during transportation.

Quality Assurance

We promise that all our products meet international quality standards and have passed ISO 9001 certification.

Contact Us

If you have any customization needs or questions, please feel free to contact us. Our professional team will provide you with the best solutions and quality services.