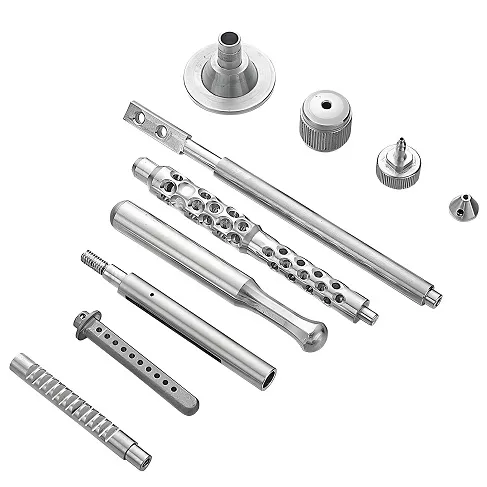

High-precision CNC shaft parts processing

Place of Origin : XiaMen, China

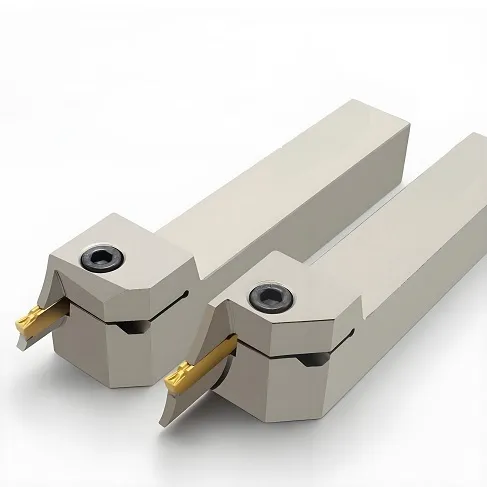

Type : Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Micro Machining or Not : Micro Machining

Model Number : finish machining

Brand Name : JSD

Application : Machinery Tools

Usage : Wear-resistance Parts

Size : Cusotmized

Feature : Wear-resistant Anti Stress Corrosion

Delivery : 10-20 Days

Description

【Product Description】:

We specialize in providing customized services for precision machining CNC shaft parts to meet a variety of high-precision and high-performance industrial needs. Our products are suitable for automation equipment, automotive industry, aerospace, precision instruments and many other fields. Through advanced technology and strict quality control, we ensure that each shaft part meets the precise requirements of our customers.

【Product Features】:

1. High precision: adopting the latest CNC machining centers to ensure that the machining precision of the parts reaches ±0.005mm.

2. Variety of materials: Stainless steel, aluminum alloy, carbon steel, alloy steel and other materials can be selected according to requirements.

3. Surface treatment: Provide various surface treatments such as anodized, electroplated, painted, polished, etc. to meet the requirements of use in different environments.

4. Fully customized: one-to-one customized service according to the drawings or samples provided by customers to ensure that the size and performance of the parts fully meet the requirements.

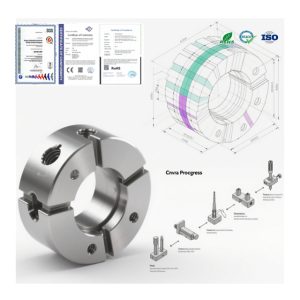

5. Quality Assurance: Strictly follow the ISO 9001 quality management system to control the quality of products throughout the process.

6. Fast delivery: Efficient production process and logistics system to ensure that the production and delivery of products can be completed within the agreed time.

【Product Advantages】:

1. Professional team: engineers and technicians with many years of experience can provide professional technical support and solutions.

2. Advanced equipment: using imported CNC processing equipment to ensure processing quality and efficiency.

3. Cost-effective: Reasonable pricing strategy to provide customers with cost-effective products.

4. After-sales service: Provide perfect after-sales service, including product consulting, technical support, troubleshooting and so on.

【Customization Process】:

1. Demand communication: customers provide specific technical requirements or drawings.

2. Program development: We develop processing programs and quotations according to customer needs.

3. Sample Confirmation: We produce samples for customer confirmation to ensure that all requirements are met.

4. Mass production: After the samples are confirmed to be correct, we enter the mass production stage.

5. Quality Inspection: Strict quality inspection is carried out after production is completed.

6. Shipment delivery: Through reliable logistics channels, the products will be safely delivered to customers.

【Application Fields】:

● Automation equipment

● Automobile parts

● Aerospace parts

● Precision instruments

● Robotics

● Medical equipment

【Buying Guide】:

● Please provide detailed product specifications and requirements so that we can provide you with an accurate quotation.

● We accept both small and large orders and welcome inquiries and cooperation from all types of customers.

● Customized lead time and price will vary depending on the complexity of the part and material selection.