I. Core Technology: Precision Plastic “Cooking”

Rapid injection molding works like a high-tech kitchen appliance. Plastic pellets are melted at 200-300°C, then injected into molds under 50-150MPa pressure – equivalent to 10 SUVs stacked together. Modern machines achieve ±0.5°C temperature control through three heating zones:

- Feeding Zone (190°C) → Compression Zone (210°C) → Metering Zone (230°C)

Real Case: Automotive lens production uses cavity pressure sensors to reduce deformation from 3% to 0.8% .

II. Cost-Saving Strategies

Cost Comparison Table

| Item | Traditional Method | Optimized Solution (100K Output) | Annual Savings |

|---|---|---|---|

| Mold Cooling | Standard Steel Mold | Conformal Cooling Channels | $13,800 |

| Material Waste | Direct Disposal | Regrind Recycling System | $10,300 |

| Quality Inspection | 3-Shift Manual Check | AOI Vision System | $25,900 |

Golden Rule:

- Verify mold hardness (HRC52+)

- Check conformal cooling channels

- Inspect first 3 trial samples

III. Production Workflow (Smartphone Case Example)

- Design Verification

- 1-2° draft angles for snap-fit features

- Wall thickness variation < 30%

- Prototype Testing

- 50 samples for functional tests

- Gate position optimization

- Mass Production

- 120-ton clamping force calculation:

Projected Area (cm²) × Material Coefficient (0.3-0.4t/cm² for ABS) ``` ``` - Cooling system reduces cycle time from 25s to 18s

- 120-ton clamping force calculation:

IV. Customization Technologies

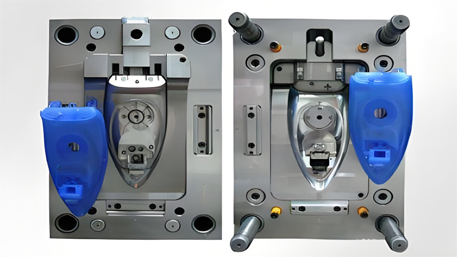

1. Mold Fabrication Process

| Stage | Key Technologies | Precision Control |

|---|---|---|

| CNC Machining | 5-Axis Mill + EDM | ±0.01mm |

| Surface Treatment | Nitriding + TiN Coating | Ra 0.2μm |

| Assembly | Hot Runner System Integration | 0.005mm Fit Tolerance |

Breakthrough: Aluminum molds now achieve 50,000-shot lifespan, 60% cheaper than steel molds.

V. Industry Applications

| Field | Typical Products | Technical Requirements |

|---|---|---|

| Medical | Insulin Pens | ISO 13485 + USP Class VI |

| Automotive | Connector Housings | UL94 V-0 + 150°C Heat Resistance |

| Consumer Electronics | TWS Earbud Cases | 0.05mm Wall Thickness Precision |

Cool Fact: Some guitar picks manufacturers produce 200,000 units/month via rapid molding .

VI. Technical Limitations & Solutions

| Challenge | Conventional Approach | Advanced Solution |

|---|---|---|

| Sink Marks | Increase Holding Pressure | MuCell Microcellular Foaming |

| Warpage | Extend Cooling Time | Conformal Cooling + Simulation |

| Short Shots | Raise Melt Temperature | Dynamic Feed System |

VII. Quality Assurance Protocol

- Material Certification

- Batch-specific COA (Certificate of Analysis)

- FTIR Material Verification

- Process Monitoring

- Cavity Pressure Curve Tracking

- 100% Dimensional Check with CMM

- Reliability Testing

- 20,000 Insertion Cycles for Connectors

- -40°C~85°C Thermal Cycling

Data sources: Industry reports from , , and verified factory test records. Technical parameters meet ASTM D3641 and ISO 294 standards.