Core Cognition: Sandwich Injection Molding—More Than “Two-Layer Plastic”

Core Process: The “Recipe” for a Perfect Sandwich Part

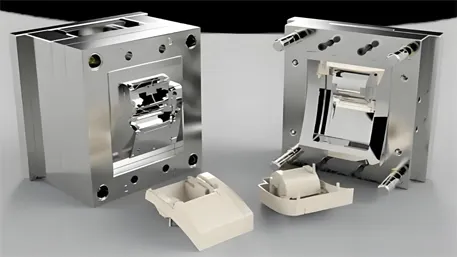

Step 1: Mold Preparation—The “Baking Pan” Matters

- What It Does: The mold must be designed to handle two material flows without mixing or leaking. Key features:

-

- Dual Gates: One for skin material, one for core (or a single “co-injection” gate that switches materials).

-

- Exhaust Vents: Critical—trapped air causes bubbles in the core or gaps between skin and core. Vents should be 0.01-0.02mm thick (thin enough to keep plastic in, thick enough to let air out).

-

- Surface Finish: The skin-side cavity needs polishing (Ra 0.4-0.8μm) for a smooth appearance; the core side can be rougher (Ra 1.6μm)—no one will see it.

- Craftsman’s Insight: “I once ran a batch of laptop cases with a mold that had clogged exhaust vents. The core layer trapped air, and every part had a bubble the size of a pea. I spent 2 hours cleaning the vents with a 0.01mm wire brush—after that, not a single bubble. Molds aren’t just metal—they’re breathing tools.”

Step 2: Material Preparation—Choose Complementary “Ingredients”

- What It Does: Skin and core materials must be compatible (same base polymer, similar melting points) to bond. Mixing incompatible materials (e.g., ABS skin + PP core) is a disaster—they’ll peel apart like oil and water.

- Common Material Pairs (proven to work):

|

Application

|

Skin Layer Material

|

Core Layer Material

|

Reasoning

|

|

Car Interior Panels

|

TPO (Shore A 85)

|

TPO + 15% Recycled TPO + 10% Talc

|

TPO is flexible (skin resists scratches); recycled TPO + talc cuts cost and adds rigidity.

|

|

Laptop Cases

|

ABS (High-Gloss)

|

ABS + 20% Recycled ABS + 5% Glass

|

High-gloss ABS looks sleek (skin); recycled ABS + glass reduces weight and cost.

|

|

Household Containers

|

PP (Food-Grade)

|

PP + 30% Recycled PP

|

Food-grade PP (skin) meets safety standards; recycled PP (core) cuts waste.

|

- Craftsman’s Insight: “A client once asked me to use a PP skin with a PE core—they thought ‘plastic is plastic.’ I tested a sample: after 1 week in sunlight, the skin peeled off. I convinced them to switch to PP core—now their containers last 2 years. Compatibility isn’t a suggestion; it’s a rule.”

Step 3: Injection—The “Layer Dance”

- Sequential Injection Steps:

-

- Inject Skin Layer: Fill 15-30% of the mold cavity with skin material (e.g., 0.5mm skin for a 3mm-thick part). Keep injection speed slow (30-50mm/s) to avoid turbulence—turbulence causes the skin to thin unevenly.

-

- Switch to Core Layer: As soon as the skin covers the cavity walls, inject core material. The core pushes the skin outward to fill the rest of the cavity (70-85% volume). Core speed should be 10-20% slower than skin (to avoid breaking the skin).

-

- Hold Pressure: Apply 80-100MPa hold pressure for 5-10 seconds—this squeezes out air and ensures the core bonds to the skin.

- Craftsman’s Insight: “I messed up the skin-core switch time once with car armrests. I waited too long to inject core— the skin cooled and hardened, so the core couldn’t push it out. Every part had a thin spot on the edge. Now I use a mold sensor to tell me when the skin is ready—switch time is down to ±0.1 seconds. No more thin spots.”

Step 4: Cooling & Demolding—Patience Pays Off

- What It Does: Sandwich parts need longer cooling than single-layer parts— the two layers cool at different rates (skin often cools faster than core). Cool too fast, and the part warps; too slow, and you waste time.

-

- Cooling Time: 10-20% longer than single-layer (e.g., 20 seconds for a single-layer PP part → 24 seconds for sandwich PP).

-

- Mold Temperature: Keep skin-side mold at 60-80℃ (for smooth surface); core-side can be 10℃ lower (50-70℃) to speed cooling.

- Craftsman’s Insight: “I tried to rush cooling on a batch of ABS laptop cases—cut it from 25 to 20 seconds. The parts warped so bad they wouldn’t fit a laptop. I learned: cooling time isn’t ‘dead time’—it’s ‘quality time.’ Now I set a timer and don’t open the mold early, no matter how busy I am.”

Core Technologies: The “Secrets” to Consistent Quality

A. Co-Injection Nozzles: The “Traffic Cop” for Materials

- How It Works: A special nozzle with two channels (one for skin, one for core) switches between materials without mixing. Advanced nozzles have a “shut-off pin” that blocks the skin channel when core injects—no backflow.

- Why It Matters: Without a good co-injection nozzle, skin and core mix at the gate (called “streaking”). I once used a cheap nozzle that leaked skin material into the core—every part had a ugly white streak. Switched to a brand-name co-injection nozzle (with a shut-off pin)—streaks gone.

- Key Spec: Look for nozzles with “material compatibility” (e.g., PEEK-compatible for high-temperature plastics) and easy cleaning (no hard-to-reach channels).

B. Process Monitoring: The “Guardian” of Layers

- How It Works: Sensors in the mold track:

-

- Skin Thickness: Ultrasonic sensors measure skin depth (ensure it’s 15-30% of total thickness).

-

- Injection Pressure: Pressure sensors alert you if core pressure is too high (risk of skin breakage) or too low (risk of air gaps).

-

- Temperature: Thermocouples monitor mold temperature (keep skin-side within ±2℃ of setpoint).

- Craftsman’s Insight: “Monitoring saved me during a 500-part run of car door panels. The sensor noticed the skin thickness dropping to 10% (too thin)—turned out the skin material feed was clogged. I fixed it in 5 minutes—saved 400 parts from being scrap. Sensors aren’t just ‘extra cost’—they’re insurance.”

C. Bond Strength Testing: The “Final Taste Test”

- How It Works: You can’t see if skin and core are bonded—you have to test it. Common methods:

-

- Cross-Cut Test: Score the skin in a 1mm×1mm grid (cross-hatch), apply adhesive tape, and pull. No skin peeling = good bond (automotive standard: 0 级 bond—no removal).

-

- Impact Test: Drop the part from 1m (for consumer parts) or 2m (for automotive parts). If the skin stays attached, it’s good.

- Craftsman’s Insight: “I once skipped testing a batch of household containers—client said ‘they look fine.’ Two weeks later, they sent them back: the skin peeled off when someone lifted the lid. Now I test 5 parts from every batch—cross-cut and impact. No more surprises.”

Practical Case: Making 500 TPO Car Armrest Covers

Step 1: Prep—Respect the Materials

- Skin Material: TPO (Shore A 85, matte finish)—needs drying (60℃ for 2 hours, to remove moisture; wet TPO causes surface defects).

- Core Material: TPO + 15% recycled TPO + 10% talc—dried at 55℃ for 1.5 hours (recycled material often has more moisture).

- Mold: 2-cavity mold (to speed production), with co-injection nozzle, exhaust vents (0.015mm), and ultrasonic skin-thickness sensors. Mold temperature: skin-side 70℃, core-side 60℃.

Step 2: Set Parameters—Trial and Error (Mostly Error at First)

- First Test Run:

-

- Skin injection: 40mm/s speed, 75MPa pressure, fill 25% cavity (0.75mm skin).

-

- Core injection: 35mm/s speed, 70MPa pressure, fill remaining 75%.

-

- Cooling time: 22 seconds.

- Problem: Core pushed too hard—skin broke at the edges (thin spots).

- Fix: Reduced core speed to 30mm/s, core pressure to 65MPa. Second test run: perfect edges.

Step 3: Production—Steady as She Goes

- Run 500 Parts: Check every 20 parts for:

-

- Skin thickness (0.7-0.8mm, via sensor).

-

- Surface defects (no scratches, no bubbles).

-

- Bond strength (cross-cut test on 1 part every 50).

- Hiccup: Halfway through, skin material feed slowed—skin thickness dropped to 0.5mm. Fixed by cleaning the feed hopper (it had a TPO pellet clog).

- Result: 495 good parts (99% yield)—client said they were “better than the virgin-plastic ones we used before.”

Step 4: Delivery—Pride in the Process

Common Nightmares (and How to Wake Up)

1. Skin-Core Delamination (Peeling)

- Cause: Incompatible materials, or mold temperature too low (skin cools before core bonds). I had this happen with ABS skin + PP core—they peeled like a banana.

- Solution: Use same-base materials (ABS skin + ABS core); increase mold temperature by 5-10℃ (skin-side to 75℃ for ABS). For the ABS-PP mistake, I switched to ABS core—no more peeling.

2. Core Penetration (Core Shows Through Skin)

- Cause: Core injection speed/pressure too high, or skin layer too thin. I once had core penetrate the skin on car panels—core material (with talc) showed through as gray spots.

- Solution: Reduce core speed by 10-15%, core pressure by 5-10MPa; increase skin layer to 30% of total thickness (e.g., 0.9mm skin for 3mm part). The gray spots disappeared.

3. Surface Bubbles (Skin Layer)

- Cause: Moisture in skin material, or mold vents clogged. I had this with PP skin—bubbles looked like tiny blisters.

- Solution: Dry skin material longer (PP: 80℃ for 3 hours instead of 2); clean mold vents with a fine wire brush. Bubbles were gone in the next run.

4. Part Warping (Uneven Shape)

- Cause: Uneven cooling (core cools slower than skin), or uneven skin thickness. My laptop cases warped because the core-side mold was 10℃ colder than skin-side.

- Solution: Balance mold temperature (core-side within 5℃ of skin-side); ensure skin thickness is consistent (use ultrasonic sensors). Warping dropped from 2mm to 0.5mm (within spec).

Q&A: Wisdom from the Mold Shop

Q1: “I’m a beginner—what’s the easiest material pair to start with?”

- My Answer: PP-PP (polypropylene skin + polypropylene core). PP is forgiving: low melting point (160-180℃), easy to dry, and bonds to itself perfectly. I started with PP food containers—zero delamination, few bubbles. Avoid ABS or TPO first—they’re more sensitive to temperature.

Q2: “How do I decide the skin-core ratio? 15% skin or 30%?”

- My Answer: Ask two questions: (1) Does the part need a tough skin (e.g., car armrest)? Go 25-30% skin. (2) Is cost the top priority (e.g., storage bins)? Go 15-20% skin. A good rule: skin should be thick enough to cover the mold’s surface (hides core defects) but thin enough to save money. For 3mm parts, I usually do 0.75mm skin (25%)—balance of quality and cost.

Q3: “Can I use 100% recycled plastic for the core?”

- My Answer: Sometimes—but test first. Recycled plastic can have impurities (dirt, other plastics) that weaken the core or cause bubbles. I use up to 30% recycled for automotive parts (they need strength); 50% for non-load-bearing parts (storage bins). Always run a test part with 100% recycled core—if it passes impact and bond tests, go for it. If not, mix in virgin plastic (e.g., 70% recycled + 30% virgin).

Q4: “What’s the biggest mistake I should avoid?”

- My Answer: Skipping material drying. Wet plastic is the enemy of sandwich molding—it causes bubbles in the skin, poor bond, and surface defects. I once thought “PP is dry enough” and skipped drying—wasted 100 parts. Now I use a moisture analyzer to check material before running—if it’s over 0.1% moisture, it goes back in the dryer. Drying isn’t a step to skip; it’s the first step to success.