Showing 305–320 of 350 results

-

Place of Origin : Fujian, China

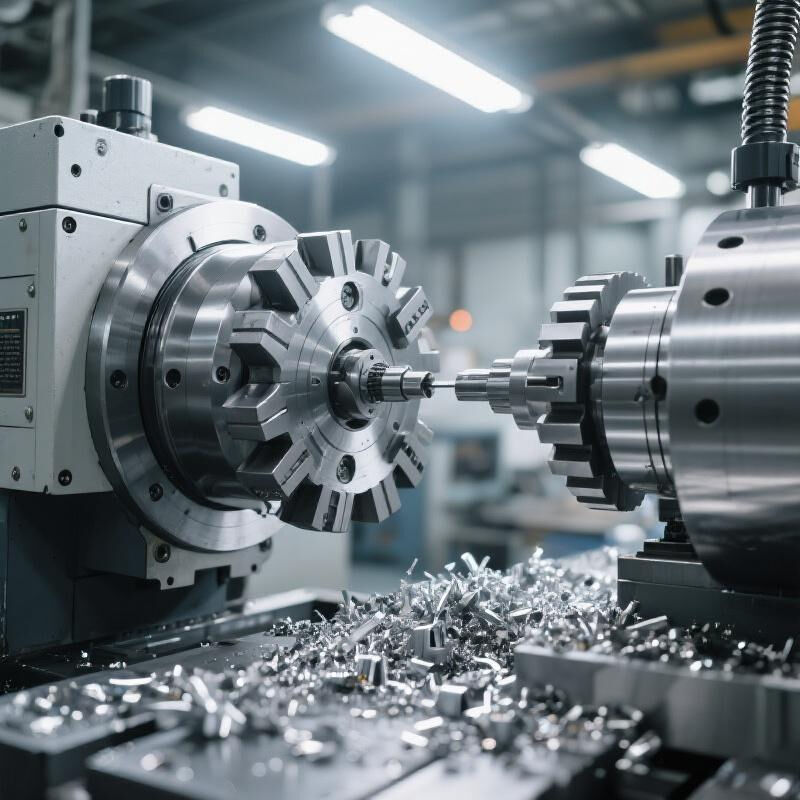

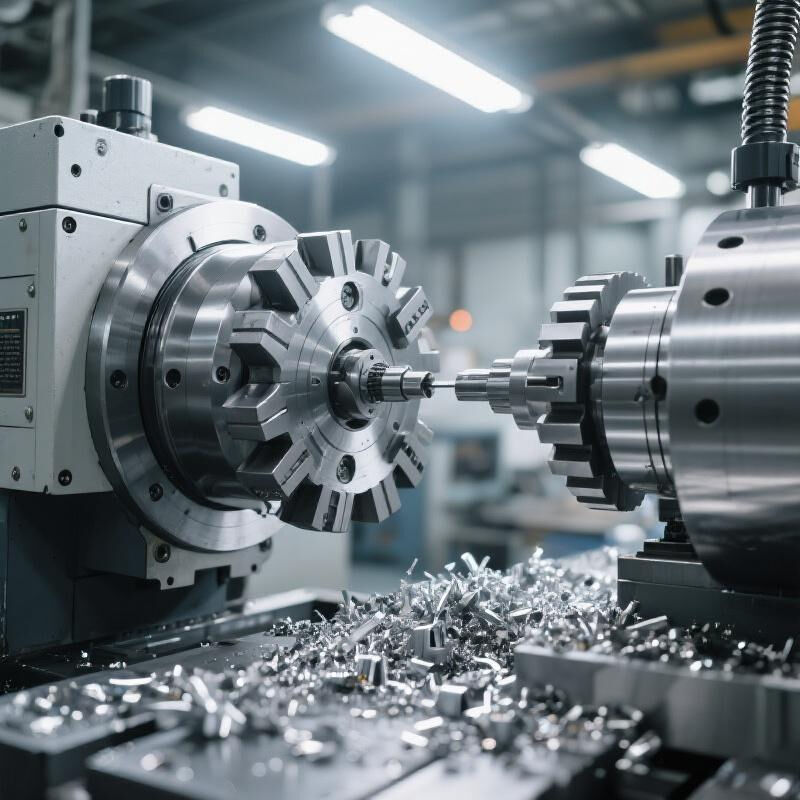

Type : Milling, Turning

Micro Machining or Not : Micro Machining

Model Number : CMP-319

Brand Name : JSD

Product name : Cnc Turning Machining Custom Made Service

Material : Customers’ Requirement

Surface treatment : Painting\Powder Coating\Plating\Polishing

Process : CNC Turning Milling

Service : Customized OEM

Equipment : 3/4/5 Axis CNC Machining Center

Size : Customizesd Size

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Certification : ISO9001

OEM/ODM : OEM ODM Non-standard Processing

-

| Attribute Category |

Attribute Details |

| Processing Service |

Moulding (Injection Molding) |

| Place of Origin |

Fujian, China |

| Brand Name |

JSD |

| Model |

IMP-235 |

| Plastic Molding Type |

Injection |

| Product Name |

Custom Plastic Pipe Fittings |

| Material |

ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT, etc. |

| Color |

Custom Color |

| Size |

Customizable Size |

| Service |

Customized OEM |

| Shape |

Customized Shapes |

| Drawing Format |

2D/(PDF/CAD), 3D(IGES/STEP) |

| Certification |

ISO9001 |

| Logo |

Customized Logo |

| Minimum Order Quantity |

1 Piece |

| Sales Unit |

Single item |

| Single Package Size |

8X8X3 cm |

| Single Gross Weight |

0.350 KG |

| Delivery Time |

1-1000 pieces: 31 days; >1000 pieces: Negotiable |

| Customization Options |

Color (MOQ: 1000 pcs), Size (MOQ: 1000 pcs), Hardness (MOQ: 1000 pcs), Characteristics (MOQ: 1000 pcs) |

-

Place of Origin : Fujian, China

Type : Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM

Micro Machining or Not : Micro Machining

Model Number : IM-73

Brand Name : JSD

Product name : Precision Metal Parts Stamping Mold Service

Material : Customers’ Requirement

Surface treatment : Painting\Powder Coating\Plating\Polishing

Process : Cnc Machining+deburrs

Service : Customized OEM

Equipment : 3/4/5 Axis CNC Machining Center

Size : Customer Size

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Certification : ISO9001

Tolerance : 0.01- +/-0.005mm

This product is designed to meet the individual needs of all kinds of hardware manufacturing enterprises, adopting advanced production technology and high-quality materials to ensure that each stamping can achieve extremely high precision and stability.

-

| Attribute Category |

Detailed Information |

| Product Type |

Nylon rubber injection molding, ABS injection molding, plastic injection molding services |

| Core Materials |

Nylon (PA), rubber (natural rubber, synthetic rubber, etc.), ABS (Acrylonitrile Butadiene Styrene copolymer), compatible with various engineering plastics and special modified materials |

| Molding Process |

High-precision injection molding process, covering thermoplastic injection and rubber injection, supporting complex processes such as multi-cavity molds, precision insert molding, and two-color injection molding |

| Technical Parameters |

– Dimensional accuracy: Up to IT7-IT8 grade, ±0.01mm for some precision parts

– Surface roughness: Ra≤0.8μm (adjustable according to product requirements)

– Mold life: ≥500,000 cycles for standard molds, ≥1,000,000 cycles for precision molds |

| Technical Advantages |

– Independent R&D of mold intelligent design system combined with Moldflow mold flow analysis to predict molding defects in advance

– Equipped with servo-electric injection molding machines with clamping force of 50-3000 tons, supporting high-speed and high-pressure molding

– Material modification laboratory capable of customizing special-performance materials such as high-temperature resistant (200℃+), low-temperature resistant (-40℃), conductive, and flame-retardant |

| Application Fields |

Automotive components (e.g., nylon gears, ABS interior parts), electrical and electronics (rubber seals, ABS casings), medical devices (precision plastic parts), industrial equipment, consumer goods, etc. |

| Customization Services |

Full-process customization from product design, mold development to mass production, supporting drawing/sample processing, small-batch trial production, and large-scale mass production |

| Service Process |

Requirement communication → Solution design → Mold manufacturing → Sample confirmation → Mass production → Quality inspection → Logistics delivery |

-

Basic Materials

Mainly brass, compatible with metal materials such as aluminum, stainless steel, copper alloy, and steel alloy

Processing Types

CNC turning, milling, drilling, wire – cutting, laser processing

Size Range

Maximum turning length: 12m (brass shaft – type parts)

Typical processing size: 5 – 40mm (brass parts)

Supports micro – machining

Processing Accuracy

Conventional accuracy: ±0.01 – 0.05mm

High accuracy: ±0.01mm (requiring special processes)

Surface roughness: Ra 0.8 – 3.2μm

Surface Treatment

Polishing, anodizing, electroplating, powder coating

Order Requirements

Minimum order quantity: 1 – 10 pieces (samples are supported)

Delivery time: 5 – 45 days (depending on complexity)

File formats: 2D (PDF/CAD), 3D (STEP/IGES)

-

|

Attribute Category

|

Detailed Information

|

|

Product Type

|

OEM Custom Injection Molding Plastic Parts (Supporting thermoplastic/thermoset plastic & rubber molding)

|

|

Core Materials

|

Includes engineering plastics such as ABS, PC, PA (Nylon), POM, PP, PE, PMMA, LCP, etc., with support for special modified materials (e.g., conductive, flame-retardant, extreme temperature-resistant)

|

|

Molding Processes

|

High-precision injection molding (including multi-color injection, insert molding, micro-molding, gas-assisted molding, and other complex processes)

|

|

Technical Parameters

|

– Dimensional Accuracy: ±0.01mm (precision parts) / ±0.05mm (standard parts)- Surface Finishing: Full-process support for electroplating, painting, silk screening, laser engraving, etc.- Mold Life: Steel molds ≥500,000 cycles, aluminum molds ≥100,000 cycles (customized by material/structure)

|

|

Technical Advantages

|

– Independently developed DFM (Design for Manufacturability) system eliminates 98% of molding risks in the design stage- Equipped with 100-3000 ton servo injection molding machine fleet, supporting 0.1g micro-parts to 5kg large components- 100,000-class cleanroom (medical-grade production line), full-process MES system traceability

|

|

Customization Capability

|

Full-process OEM services from 3D modeling → mold design → sample validation → mass production optimization, supporting:• Drawing/sample/concept design conversion• Low-volume prototyping (50-500 pieces)• Multi-material composite molding (e.g., soft-over-hard rubber molding)

|

|

Application Fields

|

Consumer electronics (phone cases/charger housings), automotive (dashboard components/new energy battery parts), medical (medical consumables/diagnostic equipment parts), industrial equipment (gears/connectors), smart home, etc.

|

|

Quality Systems

|

IATF 16949 (automotive), ISO 13485 (medical) certified, supporting PPAP, PFMEA document delivery

|

|

Service Process

|

Requirement communication (24h response) → Solution design (including DFM report) → Mold manufacturing (45-90 days lead time) → First-article inspection (3D scanning) → Mass production → Global logistics (DHL/UPS/ocean freight)

|

-

| Attribute Category |

Attribute Details |

| Industry-specific Attribute |

Shaping Mode: Plastic Injection Mould |

| Place of Origin |

Fujian, China |

| Brand Name |

JSD |

| Model Number |

IM-150 |

| Product Material |

Steel |

| Product Name |

Custom Electronic Cover Shell Parts Mould |

| Mould Material |

Steel: P20/718/H13/45#/S136, etc. |

| Keyword |

Plastic Parts Customize |

| Size |

Customized Size |

| Type |

Mold Tool |

| Cavity |

Single Cavity/Multiple Cavity |

| Mould Life |

Dependent on usage |

| Certification |

ISO9001:2008 |

| Gate Type |

OEM Gate |

| Drawing Format |

3D.STP / STEP / IGS / PRT / X_T |

| Selling Unit |

Single item |

| Single Package Size |

5X5X2 cm |

| Single Gross Weight |

0.350 kg |

| Lead Time |

1-10 pieces: 15 days; >10 pieces: Negotiable |

| Customization Options |

Custom logo (MOQ: 1,000 pcs), Custom packaging (MOQ: 1,000 pcs), Graphic customization (MOQ: 1,000 pcs) |

-

|

Attribute Item

|

Detailed Information

|

|

Product Name

|

OEM Custom Precision Plastic Injection Molding Products, including plastic parts made of TPU, PVC, PE, POM, PA, Nylon, ABS and other materials, PCB covers, and plastic parts with cutting processing

|

|

Production Mode

|

OEM custom production, supporting processing according to drawings and samples

|

|

Core Processes

|

Precision plastic injection molding process, high-precision cutting process

|

|

Applicable Materials

|

TPU (Thermoplastic Polyurethane Elastomer), PVC (Polyvinyl Chloride), PE (Polyethylene), POM (Polyoxymethylene), PA (Polyamide), Nylon, ABS (Acrylonitrile Butadiene Styrene)

|

|

Product Types

|

① Various plastic components② PCB protective covers③ Special-shaped plastic parts processed by cutting

|

-

Place of Origin : Fujian, China

Brand Name : JSD

Model Number : IM-75

Product Material : Steel

Product : Medical Grade Moulds

Product Name : OEM Precise CNC Machined P20 Medical Grade Moulds

Material : Stainless Steel

Application : Medical

Color : Customized Colors

Size : Customized Size

Service : OEM\ODM

Keyword : Mold

Drawing Format : 2D/(PDF/CAD)3D(IGES/STEP)

Certification : ISO9001

MOQ : 1piece

-

Place of Origin : XiaMen, China

Brand : JSD

Product Model : CNC-38

Material : Customer’s request

Process : CNC machining + deburring

Product Name : Specialized Precision CNC Machining Parts

Surface Finish : Customer’s request

Service : Customized OEM CNC Machining

Equipment : CNC Machining Center

Application : Industrial equipment

Color : Customized Color

Size : Customized Size

-

Place of Origin : Fujian, China

Brand Name : JSD

Model : IM-07

Usage : Table Lamp,Night Light,Floor Lamp Decoration

Keyword : Lampshade

Color : Customized Color

Size : Customized Size

Logo : Customizable Logo

MOQ : 1pcs

Features : Moisture-proof, PVC transparent sticker, Exquisite texture

OEM & ODM : Support

Installation : Easy install,Removable mounting

-

| Parameter |

Capability |

| Mold Base Standards |

HASCO • DME • LKM |

| Steel Grades |

NAK80 • S136 • P20 • H13 (HRC 48-52) |

| Tolerance Accuracy |

±0.005mm (Core/Cavity) |

| Max Mold Size |

800×600×300mm |

| Surface Finish |

SPI A1 (Ra 0.012μm) • EDM Texturing |

| Hot Runner Systems |

Mold-Masters |

| Lifespan |

500,000+ shots (Production Molds) |

| Lead Time |

15-25 Days (Standard) • 7 Days (Rush) |

| Certification |

ISO 9001 • IATF 16949 |

| Min. Part Wall Thickness |

0.15mm |

-

|

Attribute Category

|

Detailed Description

|

|

Core Material

|

High-quality brass (H59, H62, H65 optional) with excellent thermal conductivity and corrosion resistance

|

|

Processing Technology

|

CNC turning, milling, drilling, grinding, supporting integrated processing of complex structures

|

|

Precision Tolerance

|

Dimensional tolerance: ±0.01mm, surface roughness Ra≤1.6μm

|

|

Cooling Performance

|

Optimized cooling channel design, heat dissipation efficiency increased by 30%+, cooling uniformity up to 95%+

|

|

Surface Treatment

|

Options: polishing, passivation, nickel plating, chrome plating (anti-oxidation and anti-rust)

|

|

Working Environment Adaptability

|

Working temperature range: -20℃~120℃, compatible with various cooling media (water, oil, refrigerant)

|

|

Connection Method

|

Threaded (G, NPT, BSPT optional), flanged, quick-connect (interface specifications customizable on demand)

|

|

Certification Standards

|

ISO9001:2015 certified, RoHS compliant, material reports available for raw materials

|

|

Customization Range

|

Size (φ5mm~φ100mm), structure, cooling hole pattern, thread specification

|

|

|

|

-

|

Attribute Category

|

Detailed Specifications

|

Customization Options

|

Remarks

|

|

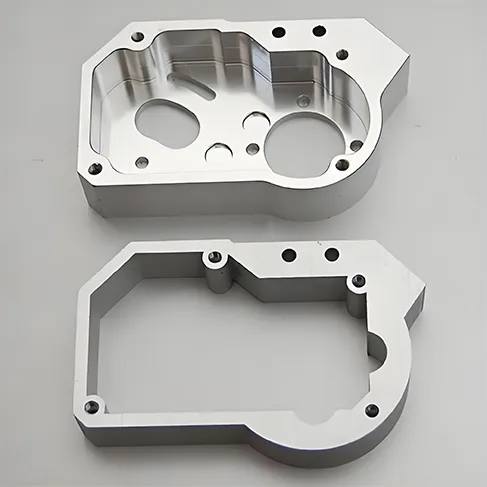

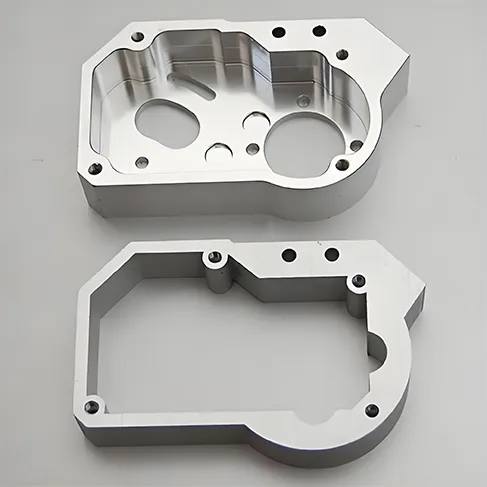

Machining Precision

|

±0.005mm

|

Standard/High Precision/Ultra-Precision

|

Complies with DIN ISO 2768 standard

|

|

Material Selection

|

Aluminum Alloy, Stainless Steel, Carbon Steel, Brass, Titanium Alloy, Engineering Plastics

|

20+ materials available

|

Recommend optimal materials based on application requirements

|

|

Machining Capability

|

3-axis/4-axis/5-axis CNC Machining Centers

|

Turning/Milling/Drilling/Boring/Tapping

|

Supports complex geometry machining

|

|

Surface Treatment

|

Anodizing, Electroplating, Sandblasting, Polishing, Heat Treatment

|

10+ surface treatment processes

|

Enhances product performance and aesthetics

|

|

Production Capacity

|

Prototyping: 1-10 piecesSmall Batch: 10-500 piecesMass Production: 500+ pieces

|

Flexible production scale

|

Supports urgent orders and long-term contracts

|

|

Quality Certification

|

ISO 9001, SGS, RoHS, CE

|

Material certificates and inspection reports

|

Full-process quality control

|

|

Lead Time

|

Samples: 3-7 daysMass Production: 7-15 days

|

Standard delivery/Rush service

|

Adjusted based on order quantity and complexity

|

|

Design Support

|

CAD/CAM design optimization, DFM analysis

|

Provide process improvement suggestions

|

Professional engineering team support

|

|

Packaging Method

|

PE bag + Carton + Wooden case

|

Custom packaging solutions

|

Shockproof and moisture-proof for safe transportation

|

-

Place of Origin : XiaMen, China

Brand : JSD

Model : CNC-41

Type : Broaching, Drilling, Etching/Chemical Processing, Laser Processing, Milling, Other Processing Services, Turning, Wire Cutting, Rapid Prototyping Micromachining or Non-Micromachining.

Product Name : CNC Machine Tool Metal Parts

Material : Stainless steel/copper/aluminum alloy

Processing method : CNC center precision machining

Surface Treatment : Powder Coating, Anodizing, Aluminum Plating, Zinc Plating, etc.

Shape : According to your drawing

Sample time : 7-10 days

Packing : According to your requirement

Tolerance : +/- 0.005 mm

Production Quantity : 1 piece

-

Place of Origin : XiaMen, China

Brand : JSD

Model : CNC-42

MOQ : 1 pc

Cost Control : Most efficient production process design

Quality control : 100% inspection of critical dimensions

Management : Skilled workers and experienced staff

Surface treatment : sandblasted, anodized, powder coated

Quality control : 100% guarantee

Application : Industrial equipment

Service : One-stop service