3D Printing vs Injection Molding in 2026: The Complete Decision Guide – Costs, Break-Even & Best Use Cases

In 2026, 3D printing (additive manufacturing) and injection molding are no longer simple opposites – new technologies have expanded 3D’s economic batch to 5,000–13,000 pieces (Formlabs Form 4L 2025 tests), while rapid tooling/hybrid processes make molding ideal for medium batches (500–10,000 pieces).

Quick Project Assessment

Use our 2026 updated data, real case studies, comparison tables, and decision checklist to choose the right process – send us your files for free DFM feedback after reading!

Cost Curve Comparison

2026 break-even points: Plastic parts at 500–13,050 pieces, Metal parts at 200–5,000 pieces

Decision Flowchart

Step-by-step decision making framework for your project

2026 Decision Matrix: Which Process to Choose?

Production Quantity: The Watershed of Cost Efficiency

2026 Cost Structure Breakdown

3D Printing Cost Structure

- •

Material cost: $2–$5 per piece (fixed per unit) - •

Machine time: $10–$30 per piece (fixed per unit) - •

Post-processing: $3–$8 per piece - •

Total: $15–$43 per piece (cost remains constant regardless of batch size)

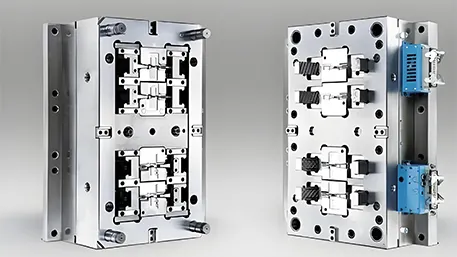

Injection Molding Cost Structure

- •

Mold cost: $20,000–$200,000 (one-time investment) - •

Material/ cycle: $1.5–$3 per piece - •

Labor/ overhead: $0.2–$0.8 per piece - •

Total: $53 per piece at 500 units → $3.5 per piece at 10,000 units

2026 Updated Break-Even Points

Plastic Parts Break-Even

Traditional resins: 500–1,000 pieces

High-performance resins: 800–1,500 pieces

Formlabs Form 4L large format: 13,050 pieces (2025 test data)

Metal Parts Break-Even

Aluminum alloys: 200–500 pieces

Stainless steel: 300–800 pieces

Binder Jetting technology: 5,000 pieces (Met3DP 2025 report)

Real-World Cost Example: 100×50×20mm ABS Part

3D Printing (MJF)

Injection Molding

Injection Molding

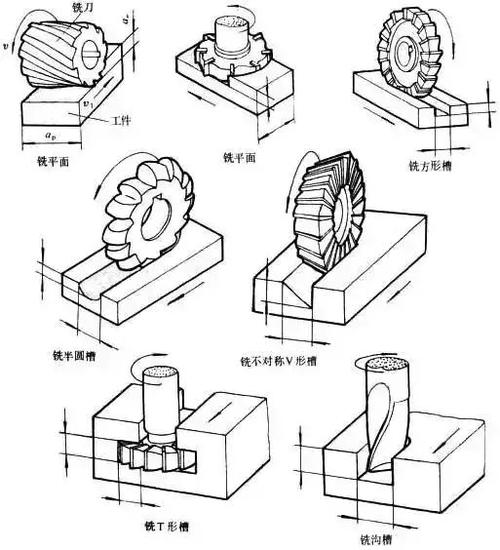

Design Complexity: The “Natural Advantages” of 3D Printing

When 3D Printing Shines

Complex Internal Structures

3D printing can create intricate internal geometries that would be impossible or extremely expensive with injection molding.

Example: Aerospace engine cooling ducts (3D printed as single piece vs 20+ parts assembly)

Personalized Customization

Medical implants, dental devices, and consumer products can be tailored to individual needs without additional tooling costs.

Example: Patient-specific scoliosis braces with 90% fit improvement

Automotive Industry Case Study: EV Battery Cooling Plates

3D Printing Solution

- ✓

Integrated complex flow channels - ✓

30% weight reduction - ✓

15% improved thermal efficiency - ✓

No assembly required

Traditional Injection Molding

- ✗

Requires 20+ separate parts - ✗

Complex assembly process - ✗

Limited flow channel design - ✗

Higher production cost for complex designs

Design Suitability Checklist

Your design is likely better suited for 3D printing if it has:

Materials & Performance: Function-Oriented Choices

2026 Material Trends & Sustainability

Sustainability Trends in 2026

Injection Molding

- • Biobased plastics market share up 20% (REACH driven)

- • Recycled content requirements in EU regulations

- • Closed-loop recycling systems becoming standard

3D Printing

- • 5–10% less material waste than subtractive methods

- • Recycled powder systems for metal printing

- • Higher energy consumption in post-processing

Material Comparison Table (2026 Prices)

Time Cost: Efficiency from Design to Production

3D Printing Timeline

- •

Design finalization: 1–3 days - •

Printing time: 24–72 hours (depending on size/complexity) - •

Post-processing: 1–3 days - •

Total: 3–7 days for first sample

Injection Molding Timeline

- •

Mold design: 5–10 days - •

Mold manufacturing: 4–12 weeks - •

Trial production: 1–3 days - •

Total: 5–14 weeks for first sample

Startup Electronics Case Study: Hybrid Timeline Advantage

Traditional Approach

- •

Design finalization: 2 weeks - •

Mold making: 8 weeks - •

First production: 1 week - •

Total: 11 weeks to market

Hybrid Approach (3D + Rapid Tooling)

- •

3D print 20 versions: 7 days - •

Rapid tooling: 2 weeks - •

Production: 1 week - •

Total: 4 weeks to market (50% faster)

Compromise Solutions & 2026 Technology Trends

Rapid Tooling: Bridging the Gap

3D Printed Molds: The Game Changer for Medium Batches

Technology Details

- • Aluminum 3D printed molds

- • Polymer composite molds

- • Hybrid metal-polymer molds

- • Surface finishing for better release

Cost & Performance

- • Cost: $5,000–$15,000

- • Lifespan: 1,000–10,000 pieces

- • Lead time: 5–15 days

- • 60% cheaper than steel molds

Ideal Applications

- • Bridge production (500–5,000 pieces)

- • Market testing

- • Customized products

- • Seasonal items

2026 Technology Trends Shaping the Industry

AI-Optimized 3D Printing

Artificial intelligence reduces print failures by 25% through real-time process monitoring and parameter optimization.

Key benefit: Lower production costs and higher quality consistency

Space 3D Printing

ESA continues microgravity 3D printing tests, with Auburn University developing semiconductor 3D printing for space applications.

Key benefit: On-demand manufacturing in remote locations

Industry 4.0 Integration

Digital twins predict both 3D printing and injection molding performance before production starts.

Key benefit: Reduced prototyping cycles and better cost forecasting

Real-World Case Studies 2025–2026

A Costly Lesson: Why You Should Always Prototype First

A startup company skipped 3D prototyping and went directly to injection molding for a complex part. The result?

What Happened

- • Mold cost: $50,000

- • First sample revealed design flaws

- • 3 mold modifications needed

- • Total additional cost: $80,000

What Could Have Been

- • 3D prototypes: $5,000

- • Design flaws identified early

- • Zero mold modifications

- • Total savings: $75,000

Your Quick Decision Checklist

Production Factors

- •

What is your expected production volume? (<500 → 3D printing) - •

What is your budget for tooling? (<$20,000 → 3D/hybrid) - •

What is your time-to-market requirement? (<4 weeks → 3D) - •

Do you need multiple design iterations? (Yes → 3D)

Design Factors

- •

Does your design have complex internal structures? (Yes → 3D) - •

Are there undercut features or overhangs? (Yes → 3D) - •

Do you need personalized/customized parts? (Yes → 3D) - •

Is lightweighting a priority? (Yes → 3D with lattice structures)

Material & Performance

- •

Do you need biocompatible materials? (Yes → 3D) - •

Are high-temperature properties required? (Yes → 3D with PEEK) - •

Is sustainability a key factor? (Yes → Compare both processes) - •

Do you need extremely high surface finish? (Ra<0.8μm → Injection)

Frequently Asked Questions

Why Choose Goldcattle for Your Manufacturing Needs

Not Sure Which Process is Right for Your Project?

Send us your STEP/IGES files for a free DFM (Design for Manufacturing) analysis and personalized recommendation on whether 3D printing, injection molding, or a hybrid approach is best for your specific needs.

What You’ll Get:

- • Free DFM feedback

- • 3D printing vs molding cost comparison

- • Material recommendations

- • Production timeline estimate

- • Quality and surface finish advice

- • 24-hour response guarantee

We’ve completed 500+ hybrid manufacturing projects for clients in Europe and America. Our IATF 16949 certification ensures the highest quality standards. Let us help you optimize your manufacturing process and reduce costs.