I. Key Points of CNC Machining for Different Steel Materials

- Carbon steel is relatively easy to machine, but its hardness and wear resistance are low.

- Due to the addition of other elements, alloy steel has a higher hardness, and higher cutting force and more durable tools are required during machining.

- Stainless steel, because of its high corrosion resistance and strength, usually requires a higher cutting speed and more precise control to avoid deformation and surface damage. It is crucial to select appropriate CNC machining parameters and tools according to the characteristics of different steel materials to ensure processing quality and efficiency.

II. Main Cutting Characteristics of CNC – Machined Stainless Steel

- High cutting force

Austenitic stainless steel is particularly prominent. Although the hardness of this material is not high (taking the grade 1Cr17Ni7 as an example, its hardness HB ≤ 187), it has good plasticity (elongation after fracture δ = 40%, reduction of area ψ = 60%). Therefore, during the cutting process, the plastic deformation is large, increasing the cutting force. When the cutting parameters are the same, the energy consumption of cutting austenitic stainless steel is about 50% higher than that of low – carbon steel.

- Severe work – hardening

Among stainless steels, austenitic and austenitic – ferritic stainless steels exhibit the most prominent work – hardening phenomenon. They have high plasticity, and the lattice undergoes strong distortion during plastic deformation. At the same time, the austenite has poor stability, and under the action of the cutting force, part of the austenite will transform into martensite. Coupled with the decomposition of compound impurities under the action of cutting heat and their dispersed distribution, a hardened layer is formed during cutting. All these make the work – hardening phenomenon more obvious.

- Easy adhesion and wear of tools

The high temperature generated during the cutting process of stainless – steel materials leads to a large affinity with the tool material. Adhesion and diffusion occur between the tool and the chip, easily forming a “built – up edge”, resulting in adhesion wear of the tool and reducing the tool life.

- High local temperature in the cutting zone

This type of material requires a large cutting force, and the power consumed for chip separation is also high, generating more cutting heat. Up to 20% of the heat can be transferred to the tool, while only 9% is transferred when machining carbon steel. At the same time, due to the poor thermal conductivity of stainless steel (the thermal conductivity of stainless steel is about 1/3 that of carbon steel), a large amount of cutting heat is concentrated in the cutting zone and the tool – chip contact interface, resulting in a very high local temperature in the cutting zone.

III. CNC Stainless – Steel Tool Parameters

- 1018 steel

- Rake angle γ

On the premise of ensuring that the tool has sufficient strength and striving to avoid chipping, a larger rake angle should be selected. Because it can not only reduce the cutting force and cutting temperature but also reduce the depth of the hardened layer. The rake angle for turning various stainless steels is generally 12 – 13°.

- Clearance angle α

On the premise of ensuring that the tool has sufficient strength, a larger clearance angle is advisable. Its reasonable value depends on the cutting thickness. During rough machining, to ensure the tool strength, a small clearance angle should be taken, generally α = 6 – 10°. During finish machining, the cutting thickness is small, and to obtain a higher machining quality, a large clearance angle should be taken, generally α = 10 – 20°. Measures such as negative chamfering on the main cutting edge can also be adopted to strengthen the tool tip and improve the wear – resistance of the tool.

- Principal cutting edge angle K, auxiliary cutting edge angle K’ and nose radius r

Generally, the principal cutting edge angle K = 45 – 75°, the auxiliary cutting edge angle K’ = 8 – 15°. To strengthen the strength of the tool tip, a nose radius r should generally be ground, and the arc radius r = 0.2 – 0.8 mm. Larger values are used for rough turning or machining large – diameter workpieces with a large feed rate; smaller values are used for finish turning or machining small – diameter workpieces with a small feed rate.

- Cutting edge inclination angle λ

The cutting edge inclination angle mainly affects the strength of the tool tip and the direction of chip flow. To enhance the strength, the cutting edge inclination angle should be negative, λ = – 8 – – 3°. For interrupted cutting, λ = – 15 – – 5°.

- Selection of chip – curling groove

Due to the high toughness and plasticity of stainless steel, chip breaking is difficult during cutting. The method of forced deformation should be used, mainly by reasonably selecting the parameters of the chip – breaking groove on the rake face and the cutting parameters. Based on the reasonable selection of cutting parameters, the method of double – cutting – edge inclination angle plus an outward – inclined chip – curling groove is generally adopted. Double – cutting – edge inclination angles are ground on the external turning tool to make the chip cross – section prism – shaped, and an outward – inclined arc – shaped chip – curling groove is ground on the rake face of the tool, so that the chip is guided and curled along the chip – curling groove into a pagoda – shaped curled chip or a short and tight spiral – curled chip.

- When machining stainless steel, the chip has strong adhesion to the tool, and built – up edge is likely to occur. Therefore, the rake face, flank face and cutting edge of the tool should have a small surface roughness (below Ra0.4) to reduce the cutting resistance, reduce chip adhesion and improve the tool life.

- Rake angle γ

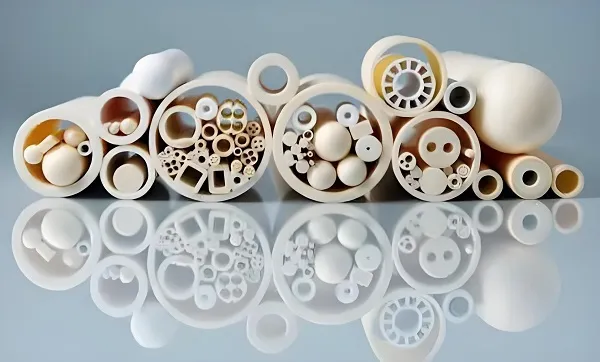

IV. Common Types of Steel Materials Used in CNC Machining

- Carbon steel

- 1018 steel

Yield strength (MPa): 310

Shear modulus (GPa): 78

Elongation at break (%): 15

Hardness (Brinell hardness): 131

Density (g/cm³): 7.87

- 1045 steel

Mechanical properties

Yield strength (MPa): 450

Shear modulus (GPa): 60

Elongation at break (%): 12

Hardness (Brinell hardness): 170

- 1215 steel

Mechanical properties

Yield strength (MPa): 415

Shear modulus (GPa): 80

Elongation at break (%): 10

Hardness (Brinell hardness): 167

Density (g/cm³): 7.87

- 1018 steel

- Alloy steel

- 4140 steel

Mechanical properties

Yield strength (MPa): 655

Shear modulus (GPa): 80

Elongation at break (%): 19

Hardness (Brinell hardness): 197

Density (g/cm³): 7.87

- 4130 steel

Mechanical properties

Yield strength (MPa): 460

Shear modulus (GPa): 80

Elongation at break (%): 20

Hardness (Brinell hardness): 217

Density (g/cm³): 7.87

- 4140 steel

- Stainless steel (such as 304, 316)

The main problem with stainless steel is the easy occurrence of tool sticking during the machining process, especially for 304 and 316 stainless steels. Due to their high toughness and adhesiveness, the tool is easily adhered by the material, resulting in increased tool wear.

V. Challenges in Custom – Machining Stainless – Steel Parts

- Thermal accumulation leading to part deformation

Unlike many other types of steel and metals, stainless steel has poor thermal conductivity. The heat generated during machining is difficult to dissipate quickly and is likely to accumulate in the cutting area. This leads to local expansion and deformation of the part, as well as surface burns, micro – cracks, and dimensional errors, accelerating the wear of the tool and CNC equipment.

- Chip adhesion and built – up edge formation

During the cutting of stainless steel, sticky chips are easily generated. These chips will adhere to the tool edge, forming a built – up edge, which not only affects the sharpness of the cutting edge but may also scratch the part surface, resulting in non – compliant surface roughness.

- High cutting force and work – hardening

Stainless steel is prone to work – hardening during the cutting process. The hardness of the cutting area rises rapidly, resulting in a significant increase in the cutting force. This not only aggravates tool wear but also makes subsequent cutting more difficult, affecting the processing efficiency and dimensional accuracy of the part.

- High demand for cutting fluid, difficult to lubricate and cool

To reduce thermal accumulation and tool wear, high – performance cutting fluids are required for machining stainless steel. However, the cooling and lubrication effects of ordinary cutting fluids are often insufficient. Special cooling fluids need to be used, and continuous and sufficient cooling must be maintained to avoid machining defects.

VI. Surface Treatment Options for Stainless – Steel Parts

- Polishing treatment

Stainless – steel polishing treatment can choose a variety of surface finishes, and common ones are #3, #4, and #8 mirror polishing. #8 mirror polishing is particularly popular because it can present a high – reflectivity, smooth and bright surface effect, which not only enhances the visual beauty of the part but also reduces the surface roughness, reduces dirt adhesion, and thus enhances corrosion resistance.

- Sandblasting and pickling

Sandblasting and pickling are common surface treatment methods for stainless – steel parts. First, the surface oxide layer is removed by sandblasting with glass beads or ceramic beads, and then it is immersed in a passivation tank for chemical pickling. This treatment can obtain a uniform matte surface, presenting a low – key and modern industrial style, which can effectively cover up small defects. Due to its strong corrosion resistance, sandblasting and pickling treatments are widely used in ships, marine equipment, and other projects that need to be exposed to harsh environments for a long time.

- Wire – drawing treatment

The wire – drawing treatment forms continuous and uniform textures on the surface of stainless steel through slight grinding, giving the part a soft silver – gray luster. Different from mirror polishing, the wire – drawn surface has a lower reflectivity, weakening the metallic feel of stainless steel and creating a more introverted texture, so it is favored by many designers.

- Electropolishing

Electropolishing dissolves the small protrusions on the surface through an electrochemical reaction, thereby obtaining a higher smoothness and finish. This treatment not only improves the corrosion resistance of the part but also reduces the microscopic roughness, making it easier to clean. It is suitable for application scenarios with high hygiene requirements, such as food processing and medical devices.