A stand for drill press is an essential accessory that provides a stable and elevated platform for drill presses, ensuring safe and precise drilling operations. It plays a key role in various settings, from industrial workshops to home DIY studios, by enhancing the functionality, safety, and efficiency of drill press use. A well – designed drill press stand prevents vibrations, reduces workpiece movement, and allows for flexible height adjustment, making it indispensable for both professional and amateur users.

1. Types of Stand for Drill Press

Fixed Drill Press Stand

Fixed drill press stands are designed with a rigid structure that offers maximum stability. They are typically made from heavy – duty materials like steel or cast iron and are permanently positioned in a workshop. These stands are ideal for heavy – duty drill presses used in industrial metalworking or woodworking, where consistent stability is crucial for handling large or thick workpieces. For example, in an automotive parts manufacturing workshop, a fixed stand ensures that the drill press remains steady when drilling through thick steel plates, preventing inaccuracies caused by vibrations.

Adjustable Drill Press Stand

Adjustable drill press stands are designed for flexibility, allowing users to modify the height of the drill press platform according to the size of the workpiece. They often feature a telescopic or sliding mechanism with locking knobs to secure the desired height. This type of stand is perfect for workshops that handle a variety of workpiece sizes, such as a woodworking studio where both small craft pieces and large furniture components need to be drilled. The adjustability also makes it easier to align the drill bit with the workpiece, reducing the risk of misdrilling.

Folding Drill Press Stand

Folding drill press stands are lightweight and portable, designed for users with limited space or those who need to move the stand between locations. They can be folded down when not in use, saving storage space. These stands are commonly used in home DIY setups, small garages, or job sites where mobility is important. While they may not offer the same level of stability as fixed stands, they are still sturdy enough for light to medium – duty drilling tasks, such as drilling holes in plywood or thin metal sheets for home projects.

Heavy – Duty Industrial Drill Press Stand

Heavy – duty industrial stands are built to withstand extreme conditions and support large, powerful drill presses used in heavy manufacturing. They feature reinforced structures, thick – gauge steel frames, and often include additional components like tool storage shelves or coolant reservoirs. These stands are essential in industries such as aerospace and construction, where drilling through thick, hard materials like alloy steel or cast iron requires maximum stability to ensure precision and safety.

2. Processable Materials for Drill Press Stand

Steel

- Carbon Steel: Carbon steel is a popular choice for drill press stands due to its high strength and affordability. Low – carbon steel is easy to shape and weld, making it suitable for basic fixed or adjustable stands. High – carbon steel, after heat treatment, offers enhanced hardness and durability, making it ideal for heavy – duty stands that need to support large drill presses and handle frequent use.

- Alloy Steel: Alloy steel, which contains elements like manganese, chromium, or nickel, provides superior strength and impact resistance compared to carbon steel. Drill press stands made from alloy steel are often used in industrial settings where the stand is subjected to heavy loads and constant vibrations. The added alloying elements also improve the steel’s weldability and resistance to wear, extending the stand’s lifespan.

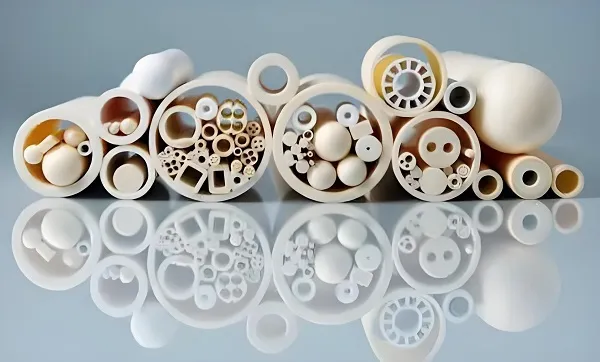

Cast Iron

Cast iron is valued for its excellent vibration – damping properties and stability. Drill press stands made from cast iron are highly rigid, which helps reduce vibrations during drilling operations, resulting in more precise holes. Cast iron stands are commonly used for heavy – duty drill presses in metalworking shops, as they can absorb the shock and vibration generated when drilling through hard materials. However, cast iron is heavier than steel, making it less suitable for portable or folding stands.

Stainless Steel

Stainless steel is used for drill press stands in environments where corrosion resistance is a priority, such as workshops with high humidity or exposure to coolants and chemicals. Grades like 304 stainless steel are resistant to rust and staining, ensuring the stand remains durable and visually appealing over time. These stands are often found in food processing facilities, marine workshops, or outdoor job sites where exposure to moisture is common.

Aluminum Alloy

Aluminum alloy stands are lightweight and corrosion – resistant, making them suitable for portable or folding drill press stands. While not as strong as steel or cast iron, aluminum alloys offer a good balance of strength and weight, making them easy to move. They are often used in home DIY setups or light – duty workshops where mobility is more important than supporting extremely heavy loads. Some aluminum stands also feature reinforced sections to enhance their stability.

3. Step – by – Step Manufacturing Process of Drill Press Stand

Material Selection and Preparation

The manufacturing process starts with selecting the appropriate material based on the type of drill press stand being produced. For example, heavy – duty fixed stands may use high – carbon steel or cast iron, while adjustable stands might use alloy steel for the frame and aluminum for moving parts. The raw materials are then cut into the required lengths and shapes using tools like plasma cutters, saws, or laser cutters. Steel plates are trimmed to size for the base, columns, and platform, ensuring precise dimensions for proper assembly.

Cutting and Shaping

After material preparation, the components are shaped using various machining processes. For steel frames, bending machines are used to create angles and curves in the steel plates, forming the base and column structure. Drilling machines create holes for bolts, hinges, or adjustment mechanisms—for example, drilling holes in the telescopic column of an adjustable stand to allow for height locking. Cast iron components are shaped using molding processes, where molten iron is poured into molds and allowed to cool, forming the base or platform with the desired shape.

Welding and Assembly

Welding is a critical step in joining the components of the drill press stand. For steel stands, arc welding or MIG welding is used to bond the base, column, and platform together, ensuring strong and durable connections. Welded joints are inspected for strength and integrity, with any defects like cracks or gaps repaired. In adjustable stands, hinges, sliding tracks, and locking mechanisms are assembled using bolts or rivets. For example, the telescopic column is attached to the base, and the platform is fitted onto the column with a sliding mechanism that allows for height adjustment.

Surface Treatment

Surface treatment is applied to enhance the durability and appearance of the drill press stand. Steel and cast iron stands are often sandblasted to remove rust, scale, or burrs, creating a smooth surface. They are then painted with anti – rust coatings or powder – coated for a tough, scratch – resistant finish. Powder coating not only protects against corrosion but also provides a decorative finish, available in various colors to suit different workshop aesthetics. Stainless steel stands may undergo polishing to improve their surface smoothness and corrosion resistance.

Quality Inspection and Testing

After assembly and surface treatment, the drill press stand undergoes rigorous quality inspection. Inspectors check the dimensions of the stand, ensuring the base is level, the column is vertical, and the platform is flat. They test the stability of the stand by applying weights to simulate the load of a drill press and workpiece, checking for any wobbling or movement. For adjustable stands, the height adjustment mechanism is tested to ensure it locks securely in place and moves smoothly. Load – bearing tests are also conducted to verify that the stand can support the specified weight without bending or breaking.

Packaging and Delivery

Once the stand passes inspection, it is packaged for delivery. Heavy – duty stands may be wrapped in protective film and secured on pallets to prevent damage during transportation. Folding or portable stands are often packed in cardboard boxes with foam padding to protect delicate components. Each package includes assembly instructions, necessary hardware (like bolts and nuts), and any additional accessories, such as tool trays or clamping devices. The packages are labeled with product specifications, including dimensions, weight capacity, and material, to help customers identify the right stand for their needs.

4. Customizing Drill Press Stand

Sharing Requirements

To get a custom – made drill press stand, customers first need to provide detailed requirements. This includes specifying the size of the drill press the stand will support (weight, base dimensions), the maximum workpiece size to be drilled, and any special features needed, such as adjustable height, tool storage, or corrosion resistance. Providing drawings or sketches in formats like PDF or CAD can help clarify the design. For example, a customer in a metalworking shop might request a stand with a 300kg weight capacity, a 60cm x 60cm platform, and a height adjustment range of 80cm to 120cm.

Engineer Consultation

The manufacturer’s engineering team reviews the customer’s requirements to assess feasibility. They provide advice on material selection—for instance, recommending alloy steel for a heavy – duty stand or stainless steel for a humid environment. They also suggest design modifications to enhance stability, such as adding reinforcing ribs to the base or using a triangular frame structure. The team calculates the load – bearing capacity and provides an estimate of cost and lead time, considering factors like material availability and manufacturing complexity.

Prototype Production

For complex custom designs, a prototype is produced to test functionality and stability. The prototype is built using the same materials and manufacturing processes as the final product. Customers can inspect the prototype, test the height adjustment (if applicable), and check how well it supports their drill press. Any issues, such as instability at maximum height or difficulty locking the platform, are addressed by the engineering team, who modify the design before moving to full production.

Bulk Production

After prototype approval, bulk production begins. The manufacturing process is closely monitored to ensure consistency, with regular quality checks at each stage. For example, welded joints are inspected for strength, and surface treatments are checked for even coverage. Once production is complete, each stand undergoes a final inspection to ensure it meets the customer’s specifications. The stands are then packaged and delivered, with the manufacturer providing assembly support if needed.

5. Application Fields of Drill Press Stand

Industrial Manufacturing

In industrial manufacturing facilities, drill press stands are used to support large, powerful drill presses for precision drilling in metalworking, automotive parts production, and aerospace component manufacturing. They ensure stability when drilling through thick steel, aluminum, or titanium parts, where even small vibrations can lead to inaccuracies. Heavy – duty fixed stands are commonly used here, often integrated into production lines to streamline drilling operations.

Woodworking Workshops

Woodworking workshops rely on drill press stands to handle a variety of wood drilling tasks, from creating small holes for screws to large, deep holes for dowels. Adjustable stands are popular here, as they allow woodworkers to adjust the platform height to accommodate different workpiece sizes, from small craft pieces to large wooden panels. The stability provided by the stand prevents splintering and ensures clean, precise holes in softwoods and hardwoods alike.

Home DIY and Hobby Studios

Home DIY enthusiasts and hobbyists use drill press stands to enhance their home workshops. Folding or portable stands are ideal for small spaces, as they can be stored away when not in use. These stands support medium – duty drill presses for tasks like building furniture, repairing appliances, or creating crafts. They make home drilling safer and more accurate, reducing the risk of hand fatigue or workpiece slippage compared to handheld drilling.

Construction and Job Sites

On construction sites, portable drill press stands are used for on – site drilling tasks, such as drilling holes in metal studs, wooden beams, or concrete formwork. Stands with rugged designs and corrosion – resistant materials can withstand the harsh conditions of construction sites, including dust, moisture, and rough handling. They provide a stable platform for drilling in temporary setups, ensuring that structural components are drilled accurately to meet building specifications.

6. Manufacturing Challenges of Drill Press Stand

Ensuring Structural Stability

One of the biggest challenges is ensuring the stand can support the weight of the drill press and workpiece without wobbling or bending. Poor stability can lead to inaccurate drilling, tool damage, or safety hazards. To address this, manufacturers use computer – aided design (CAD) to simulate load distribution and stress points, adding reinforcing structures like gussets or cross – braces to weak areas. They also select high – strength materials and ensure precise welding to create strong joints.

Achieving Precise Adjustment Mechanisms

For adjustable stands, designing smooth and secure height adjustment mechanisms is challenging. The mechanism must allow easy height changes while locking firmly in place to prevent sudden movement during drilling. Manufacturers address this by using high – quality sliding tracks, precision – machined locking pins, and durable springs or latches. They test the adjustment mechanism repeatedly to ensure it operates smoothly even after extended use.

Balancing Weight and Portability

For folding or portable stands, balancing weight and portability with stability is a key challenge. Making the stand too lightweight can compromise stability, while making it too heavy reduces portability. Manufacturers solve this by using lightweight yet strong materials like aluminum alloys, optimizing the frame design to reduce weight without sacrificing strength, and adding features like ergonomic handles for easy lifting.

7. Expert Manufacturing Tips for Drill Press Stand

Optimizing Frame Design

Using a triangular frame structure for the base and column enhances stability, as triangles are inherently rigid shapes. Adding reinforcing ribs to the platform and base distributes weight evenly, reducing the risk of bending. CAD software is used to model the frame and simulate stress under different loads, allowing manufacturers to refine the design for maximum strength.

Selecting the Right Welding Technique

For steel stands, using MIG welding for thick sections ensures strong, durable joints, while TIG welding is used for thin or precision components to create clean, neat welds. Post – welding heat treatment can reduce stress in the welded joints, preventing cracks and improving overall structural integrity.

Enhancing Surface Protection

Applying a multi – layer surface treatment, such as a primer followed by powder coating, provides superior corrosion resistance. For stands used in harsh environments, adding a zinc plating layer before painting further enhances rust protection. Regular testing of surface treatments, such as salt – spray tests, ensures they meet durability standards.

8. Common Questions About Drill Press Stand

Q: What weight capacity should I choose for a drill press stand?

A: The weight capacity should be at least 1.5 times the weight of your drill press plus the maximum workpiece weight. For example, if your drill press weighs 100kg and you drill workpieces up to 50kg, choose a stand with a minimum 225kg capacity to ensure safety and stability.

Q: Can a drill press stand be used for other tools?

A: Yes, some versatile stands can support other tools like bench grinders or sanders, provided the weight capacity and platform size are suitable. However, ensure the stand is stable enough for the tool’s operation to avoid accidents.

Q: How do I maintain a drill press stand?

A: Regularly inspect the stand for loose bolts or welds and tighten them as needed. Clean the surface to remove dust and debris, and touch up paint or powder coating to prevent rust. For adjustable stands, lubricate the sliding mechanisms with machine oil to ensure smooth operation.

9. Get Your Custom Drill Press Stand Today

Need a reliable drill press stand for your workshop? Our company specializes in manufacturing high – quality drill press stands, from fixed heavy – duty models to portable folding designs. We use premium materials like alloy steel, cast iron, and stainless steel, with advanced welding and surface treatment techniques to ensure durability. Our team of engineers can create custom stands tailored to your specific needs, whether you require a high – capacity industrial stand or a space – saving home DIY stand. Contact us today with your requirements, and let us help you enhance your drilling precision and safety!