Rapid Injection Molding: Technology, Process Innovations, and Industry Applications

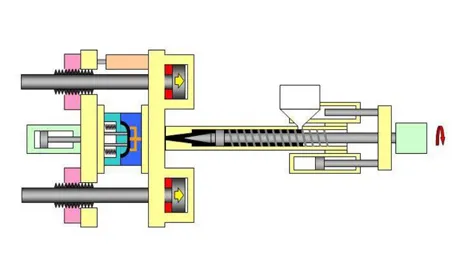

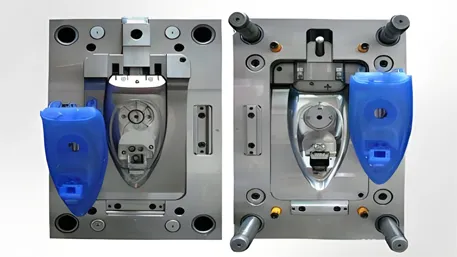

1. Core Principles: Compressing Time Without Compromising Quality Rapid injection molding bridges prototyping and mass production by achieving 85% shorter lead times than conventional methods. Unlike standard 8-12 week cycles, rapid tooling delivers first…