Exploration: What is the 4t Rule in Sheet Metal?

The answer is: The 4t rule is an important safety guideline for sheet metal bending! It tells us that the minimum inside bend radius should be four times the material…

The answer is: The 4t rule is an important safety guideline for sheet metal bending! It tells us that the minimum inside bend radius should be four times the material…

The minimum bend radius (MBR) for sheet metal is the smallest inner radius achievable during bending without causing material cracking, tearing, or excessive deformation. It depends on material ductility, thickness,…

The rule of thumb for sheet metal refers to practical design and processing guidelines accumulated from experience, simplifying complex engineering calculations into easy-to-remember principles—like “bend radius ≥ material thickness” or…

The five key sheet metal operations are shearing, bending, punching, drawing, and forming. Shearing cuts sheets to size; bending shapes them into angles; punching creates holes or features; drawing forms…

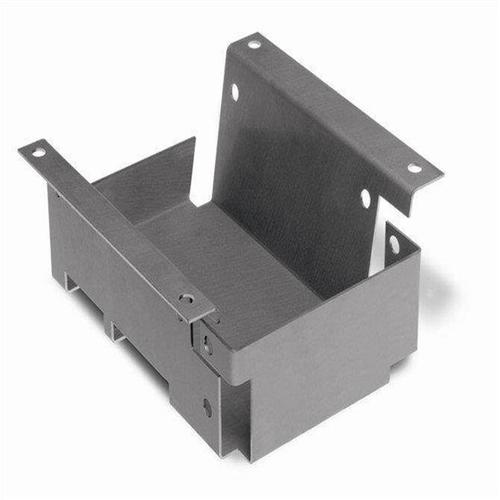

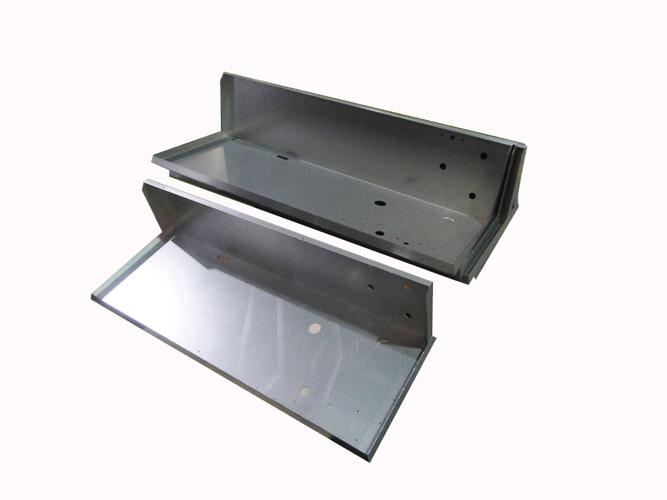

The core difference between sheet metal parts and machined parts lies in raw material form and processing methods: sheet metal parts are “shaped” from thin metal sheets through cutting, bending,…

The 4T rule is a core guideline in sheet metal design to ensure bending accuracy, requiring functional features (e.g., holes, bosses) to be at least 4 times the material thickness…

In the wave of the upgrade of China’s sheet metal industry, Xiamen Goldcattle, with its innovative service model of the “Technical Expert Assistance Program for Enterprises”, has set a new…