- Milling Processing

- 3/4/5-Axis Milling Centers:

- 3-Axis Milling: Supports basic structure processing such as planes, grooves, and bosses with standard tolerances of ±0.01mm. Ideal for rapid prototyping and simple parts, with a minimum feature size of 0.5mm.

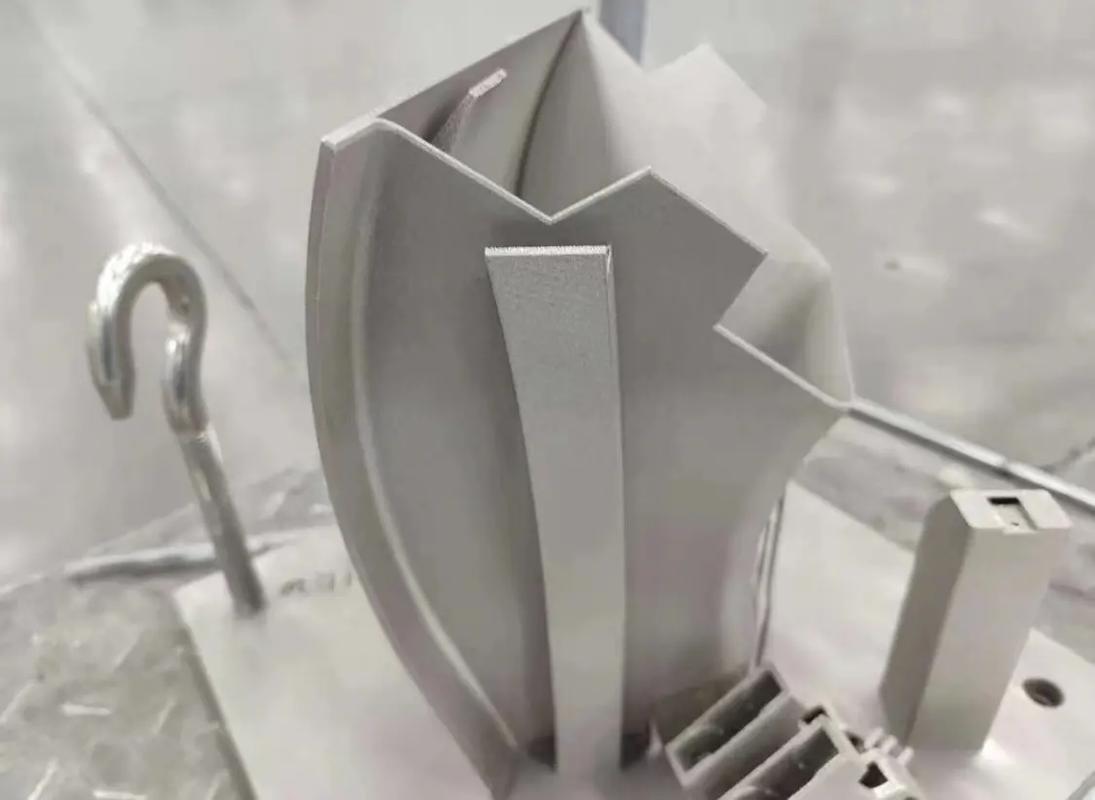

- 5-Axis Machining: Equipped with imported machines like Mazak and Haas, capable of multi-angle precision processing for complex surfaces (e.g., aerospace blades, medical joints). Reduces clamping times, achieving a processing accuracy of ±0.005mm and a maximum processing size of 1500×800×600mm.

- Turning Processing

- CNC Lathes (including dual-spindle and live tooling turret models):

- Supports external/internal cylindrical and thread processing for shaft/disc parts. Maximum processing diameter: 320mm, length: 1000mm. Capable of precision threads (inch/metric/custom) and radial milling for high-precision rotary parts like automotive drive shafts and bearing sleeves.

- Special Processing

- EDM Spark Machining/Wire Cutting: For hard materials (e.g., titanium alloy, quenched steel) and complex internal cavities. Minimum hole diameter: 0.1mm, surface roughness Ra≤0.8μm, meeting requirements for precision molds and aerospace fasteners.

- Protective Treatments: Anodizing (aluminum, 5-25μm thickness), galvanizing/nickel plating (steel, salt spray test ≥500 hours), passivation (stainless steel, compliant with ASTM A967).

- Functional Treatments: PTFE coating (self-lubricating, friction coefficient ≤0.1), hard anodizing (wear-resistant, 25-100μm thickness), conductive coating (plating on plastics for EMI shielding).

- Decorative Treatments: Powder coating (RAL color customization, matte/gloss finishes), anodizing coloring (multicolor aluminum), laser marking (permanent part serial number labeling).

- Standard Processing: Tolerances ±0.01mm (metal)/±0.02mm (plastic), suitable for general industrial parts.

- Precision Processing: Tolerances ±0.005mm (metal)/±0.01mm (plastic), ideal for critical components like medical implants and aerospace fasteners.

- Ultra-Precision Processing: Supports ±0.001mm-level tolerances (customized). Full inspection via CMM coordinate measuring machine (accuracy 0.0015mm), with a temperature-controlled inspection room (20±0.5℃) to ensure measurement precision.

- First Article Inspection (FAI): Conducted for each order before production, providing detailed reports on dimensions, materials, and surface treatment.

- Process Control: Real-time monitoring of machine vibration, cutting temperature, etc. Automatic tool setters (accuracy ±0.002mm) reduce human error.

- Certifications: Certified to IATF 16949 (automotive) and ISO 13485 (medical devices). Provides material certifications (e.g., AMS 4928 titanium alloy reports) and ROHS compliance statements.

- Online Quoting: Upload STEP/STL files to get detailed quotes (material, process, price, lead time) within 15 minutes. Supports DFM (Design for Manufacturability) analysis to automatically suggest design optimizations (e.g., avoiding sharp corners, deep cavity improvements).

- Flexible Production:

- Prototype Sampling: 1-3 working days delivery (simple aluminum parts as fast as 24 hours), supports 1-piece order.

- Low-Volume Production: 10-1000 pieces, 5-10 working days delivery. Uses “multi-part per blank” nesting to reduce material waste.

- Mass Production: Over 1000 pieces, automated production line scheduling reduces unit cost by 15%-20% compared to industry average, lead time 2-4 weeks.

- Global Delivery: Supports international logistics via DHL/UPS/FedEx, delivering to major North American and European markets within 72 hours. Domestic orders default to SF Express.

- Special Requirement Support:

- Thread customization: Inch UNF/UNC, British BSW, Japanese JIS, and non-standard threads.

- Precision fitting: Bearing hole grinding (H7/g6 accuracy), interference fit processing.

- Lightweight design: Honeycomb structures, thin-walled parts (wall thickness ≥0.8mm), vacuum adsorption fixtures reduce deformation.

- Project: Carbon fiber wing connector for a UAV manufacturer (material: Grade 5 titanium alloy)

- Solution: 5-axis milling for complex surfaces, combined with EDM wire cutting for internal holes. Hard anodizing surface treatment, tolerance ±0.003mm, meeting high-altitude load requirements.

- Project: Orthopedic knee prosthesis (material: medical-grade 316L stainless steel)

- Solution: Combined turning-milling processing, electropolished surface (Ra≤0.2μm). Certified to ISO 13485, provides biocompatibility test reports.

- Project: High-end mobile phone aluminum mid-frame (material: 6061-T6)

- Solution: 3-axis high-speed milling, anodizing coloring (matte silver). Supports 0.3mm thin-wall processing, daily capacity 5000 pieces, meeting new product launch needs.

- Geometric Features:

- Inner corner radius ≥0.5mm, avoid sharp angles smaller than tool radius (common tool radii: 0.8mm/1.5mm/3mm).

- Deep cavity depth ≤5x diameter (e.g., 10mm diameter hole, depth ≤50mm) to reduce tool vibration risk.

- Material Selection:

- Prioritize aluminum (6061) or ABS for prototypes (low cost, easy processing); switch to 7075 or PA66 for mass production based on strength needs.

- Tolerance Labeling:

- Use loose tolerances (±0.05mm) for non-fitting surfaces, and strict tolerances (±0.01mm) for critical fitting surfaces (e.g., guide pillar holes) to reduce processing costs by 30%.