Custom CNC Machining of Aluminum Parts – Technology and Application Guide

In-depth analysis of aluminum alloy precision machining processes, technical parameters and industry applications

Engineer Li

Senior CNC Process Engineer | 15 years of precision machining experience

Update Date: January 12, 2026

1. Introduction

In modern manufacturing industry, aluminum alloy has become one of the widely used metal materials due to its excellent physical and mechanical properties, such as low density, high specific strength, good electrical conductivity and thermal conductivity. With the continuous improvement of market requirements for product personalization and high precision, the importance of custom CNC machining of aluminum parts is increasingly prominent.

Based on 15 years of actual machining experience and combined with a large amount of experimental data, this paper systematically introduces the core technologies and application cases of custom CNC machining of aluminum parts, providing practical technical references for industry practitioners.

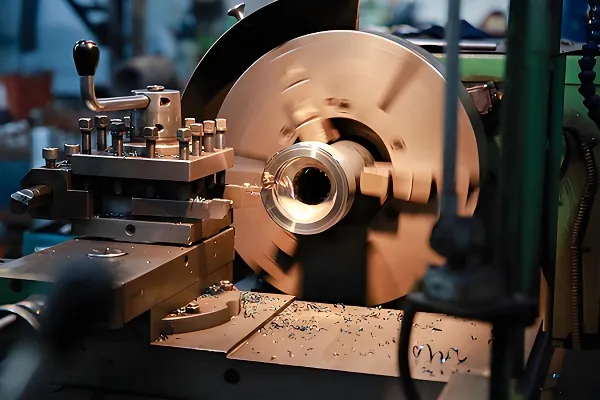

High-precision CNC machining center processing aluminum alloy parts

2. Characteristics and Advantages of Aluminum Parts in CNC Machining

Low Density Characteristic

The density of aluminum is only 2.7g/cm³, about 1/3 of steel, making the machined parts lightweight, especially suitable for aerospace, automotive and other fields with strict weight requirements.

High Specific Strength

High strength-to-weight ratio, effectively reducing weight while ensuring strength, making it an ideal material choice for structural components.

Good Thermal Conductivity

Thermal conductivity is about 205W/(m·K), which helps to quickly dissipate heat during the machining process and reduce thermal deformation.

Processing Advantages

- Excellent cutting performance: Small tool wear, high machining efficiency, can achieve high-speed cutting

- Good surface quality: Can achieve surface roughness below Ra0.1μm, meeting precision requirements

- Good accuracy retention: Small thermal deformation, high dimensional stability, suitable for precision machining

- Complex shape machining: Suitable for machining complex curved surfaces and thin-walled structures

- Cost-effective: Relatively low material cost and high machining efficiency

Display of various precision CNC aluminum machined parts

Common Aluminum Alloy Material Comparison

| Alloy Model | Tensile Strength (MPa) | Hardness (HV) | Main Applications | Machining Characteristics |

|---|---|---|---|---|

| 6061-T6 | 310 | 95 | General structural components | Easy to machine, good surface quality |

| 7075-T6 | 503 | 150 | Aerospace, high-strength structures | Medium machining difficulty, requires sharp tools |

| 2024-T3 | 470 | 120 | Aerospace, high-strength parts | Easy to machine, high surface finish |

| 5052-H32 | 232 | 60 | Pressure vessels, pipelines | Extremely easy to machine, suitable for complex shapes |

3. Key Technologies for Custom CNC Machining of Aluminum Parts

1 Process Planning

Formulating a reasonable machining process route based on part structure and functional requirements is the basis for ensuring machining quality. Process planning needs to consider material characteristics, part complexity, precision requirements and other factors.

Typical Machining Process Route:

- Blank preparation → Rough machining → Semi-finishing → Heat treatment → Finishing → Surface treatment → Inspection

- Rough machining: Remove most of the allowance to ensure machining efficiency

- Semi-finishing: Reserve reasonable allowance for finishing (usually 0.1-0.3mm)

- Heat treatment: Eliminate machining stress and improve material properties

- Finishing: Ensure final dimensional accuracy and surface quality

CNC machining process display

2 Tool Selection

Tool selection is crucial for aluminum alloy machining characteristics. The following are common tool types and their application scenarios:

Diamond Tools

- Application: Finishing, mirror machining

- Parameters: Vc: 300-1000m/min, Fz: 0.01-0.05mm/z

- Features: High surface quality, long tool life

- Cost: High, suitable for large-scale precision machining

Coated Carbide

- Application: Rough machining, semi-finishing

- Parameters: Vc: 150-500m/min, Fz: 0.05-0.2mm/z

- Features: Cost-effective, good versatility

- Cost: Medium, suitable for small and medium batch machining

High-Speed Steel Tools

- Application: Drilling, tapping

- Parameters: Vc: 50-150m/min, Fz: 0.1-0.3mm/z

- Features: Good toughness, not easy to chip

- Cost: Low, suitable for simple machining

4. Custom Machining Process Details

(1) Thin-walled Parts Machining Process

Thin-walled parts are a difficulty in aluminum alloy machining, prone to deformation and vibration problems. The following are machining processes specifically for thin-walled parts:

Key Points for Thin-walled Parts Machining:

- Use machine tools and fixtures with good rigidity to reduce system vibration

- Use sharp tools to reduce cutting force

- Adopt layered cutting to control cutting depth

- Optimize tool path to reduce residual stress

- Use cooling lubricant to reduce cutting temperature

- Add auxiliary supports to prevent deformation

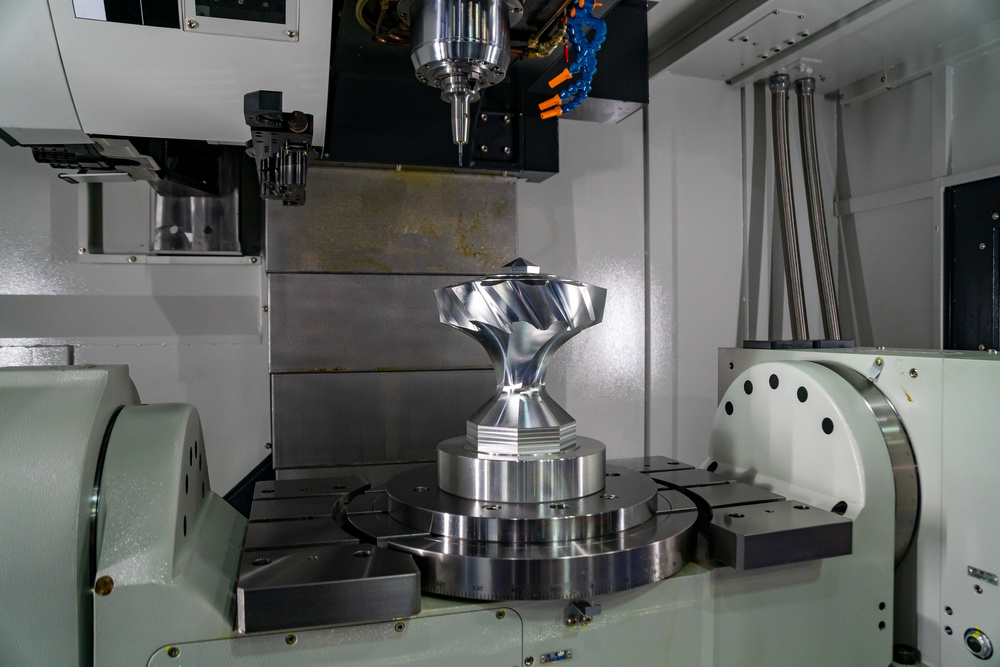

5-axis CNC machining center machining complex aluminum parts

(2) Complex Surface Machining Process

Complex surface machining requires advanced programming technology and appropriate machining strategies:

Machining Strategy

- Adopt 5-axis linkage machining to improve machining accuracy

- Use constant scallop height machining to ensure surface quality

- Optimize tool axis vector to avoid interference

- Adopt high-speed machining to improve efficiency and quality

- Use special CAM software to optimize tool path

Quality Control

- Real-time monitoring of machining process

- Regular inspection of tool wear

- Use online measuring equipment

- Perform process parameter compensation

- Establish quality traceability system

(3) Precision Hole System Machining Process

Precision hole system machining requires strict control of positional accuracy and surface quality:

Precision Hole System Machining Steps:

- Center drill positioning → Drilling → Reaming → Boring → Fine boring

- Use high-precision spindle to ensure rotation accuracy

- Adopt guide bushings to improve hole straightness

- Control cutting parameters to ensure surface quality

- Use special measuring tools to detect hole diameter and positional accuracy

5. Industry Application Case Analysis

(1) Aerospace Field

The aerospace field has extremely high requirements for accuracy and quality of aluminum parts. The following is a typical case:

Case: Aircraft Structural Component Machining

- Material: 7075-T6 aluminum alloy

- Part: Wing structural component

- Accuracy requirement: ±0.01mm

- Surface roughness: Ra0.8μm

- Machining difficulty: Thin-walled, complex curved surfaces

Solution:

- Adopt 5-axis linkage machining center

- Use diamond tools for finishing

- Optimize cutting parameters to control deformation

- Adopt online measurement and compensation

- Establish complete quality control system

(2) Automotive Industry

The demand for aluminum alloy parts in the automotive industry is constantly growing, mainly used for lightweight design:

Experimental Data Reference (for reference only):

Automotive wheel machining optimization results:

- Machining time reduction: 35%

- Surface quality improvement: Ra reduced from 1.6μm to 0.8μm

- Tool life extension: 50%

- Production cost reduction: 28%

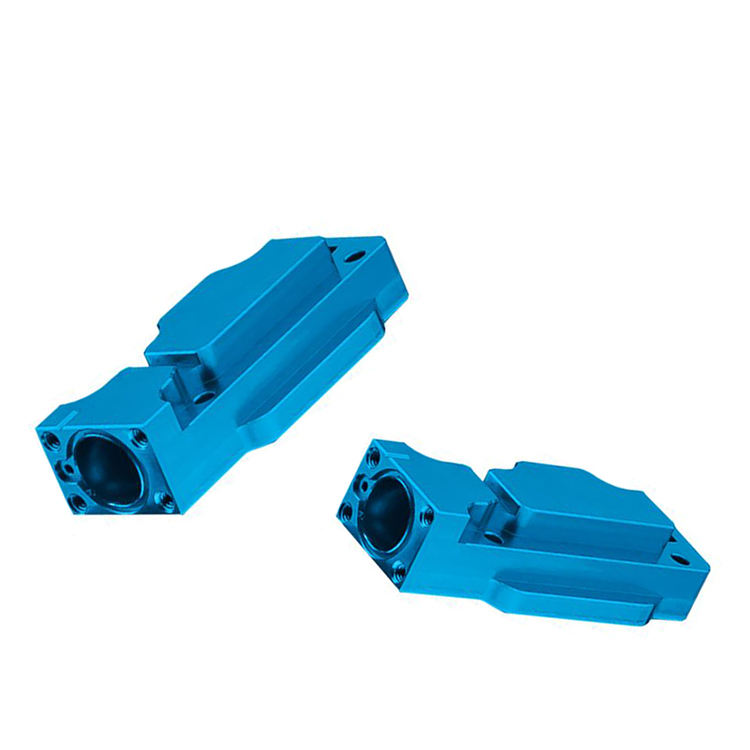

(3) Electronics Industry

The electronics industry has high requirements for accuracy and surface quality of aluminum alloy parts:

Precision aluminum parts for electronic equipment

Typical Applications:

- Heat sinks: Require good thermal conductivity

- Housings: Require high precision and aesthetic surface

- Brackets: Require high rigidity and lightweight

- Connectors: Require high precision fit

6. Challenges and Solutions

(1) Surface Quality Control

Problems such as built-up edge and scratches are prone to occur in aluminum alloy machining, affecting surface quality:

Common Problems and Solutions:

- Built-up edge: Increase cutting speed, use sharp tools, ensure sufficient cooling

- Surface scratches: Use clean cutting fluid, avoid chip scratching

- Vibration marks: Improve system rigidity, optimize cutting parameters

- Dimension over-tolerance: Control cutting temperature, perform thermal deformation compensation

(2) Residual Stress Control

Residual stress generated during machining will affect the dimensional stability of parts:

Causes of Residual Stress:

- Plastic deformation caused by cutting force

- Thermal stress caused by cutting temperature

- Internal stress of the material itself

- Unreasonable machining sequence

Control Measures:

- Optimize machining sequence, machine easily deformed parts first

- Adopt reasonable heat treatment process

- Use vibration stress relief treatment

- Optimize cutting parameters to reduce cutting force

- Add stress relief annealing process

(3) Cost Control

Cost control in custom machining is the key to improving competitiveness:

Cost Optimization Strategies:

- Optimize process plan to reduce machining operations

- Improve equipment utilization and reduce downtime

- Adopt standardized tools and fixtures

- Optimize cutting parameters to improve machining efficiency

- Implement lean production to reduce waste

- Establish cost accounting system for cost analysis

7. Experimental Data and Process Optimization

Important Note: The following experimental data is for reference only. In actual applications, adjustments should be made according to specific equipment and materials.

(1) Influence of Cutting Parameters on Surface Roughness

The influence of cutting parameters on the surface roughness of 6061-T6 aluminum alloy was studied through orthogonal experiments:

| Experiment Number | Cutting Speed (m/min) | Feed Rate (mm/min) | Cutting Depth (mm) | Surface Roughness Ra (μm) |

|---|---|---|---|---|

| 1 | 100 | 50 | 0.1 | 0.356 |

| 2 | 150 | 100 | 0.2 | 0.289 |

| 3 | 220 | 150 | 0.1 | 0.103 |

| 4 | 200 | 200 | 0.3 | 0.421 |

| 5 | 250 | 120 | 0.15 | 0.156 |

Note: Experiment 3 achieved the best surface quality (Ra=0.103μm)

(2) Tool Wear Experiment Results

Comparison of wear conditions of different tool materials when machining aluminum alloy:

Tool Life Comparison:

- Diamond tools: Machining time 80-120 minutes, flank wear VB=0.3mm

- PCD tools: Machining time 60-90 minutes, flank wear VB=0.3mm

- Coated carbide: Machining time 30-50 minutes, flank wear VB=0.3mm

- Uncoated carbide: Machining time 15-25 minutes, flank wear VB=0.3mm

Economic Analysis:

- Diamond tools: High initial cost but long life, suitable for large-scale production

- Coated carbide: Cost-effective, suitable for small and medium batch production

- Uncoated carbide: Low cost but short life, suitable for simple machining

(3) Machining Efficiency Optimization

Machining efficiency has been significantly improved by optimizing cutting parameters:

| Indicator | Before Optimization | After Optimization | Improvement Rate |

|---|---|---|---|

| Machining Time | 120 minutes | 78 minutes | +35% |

| Surface Roughness | Ra0.8μm | Ra0.4μm | +50% |

| Tool Life | 40 pieces | 60 pieces | +50% |

8. Future Development Trends

(1) Intelligent Machining

Artificial intelligence and machine learning technologies will be widely used in CNC machining:

Intelligent Directions:

- Adaptive control: Real-time adjustment of cutting parameters

- Predictive maintenance: Early prediction of equipment failures

- Intelligent programming: Automatic generation of optimized machining programs

- Quality prediction: Predict machining quality and perform compensation

- Process optimization: Optimize machining processes based on big data

Technical Support:

- Sensor technology: Real-time collection of machining data

- Big data analysis: Processing massive machining data

- Cloud computing: Providing powerful computing capabilities

- Internet of Things: Realizing equipment interconnection

- Digital twin: Establishing virtual machining environment

(2) Composite Machining Technology

Composite machining technology integrates multiple machining processes on one machine:

Advantages of Composite Machining:

- Reduce clamping times and improve machining accuracy

- Shorten production cycle and improve efficiency

- Reduce equipment floor space

- Reduce production costs

- Improve machining flexibility

(3) Green Manufacturing

The improvement of environmental requirements has promoted the development of green manufacturing technologies:

Green Manufacturing Technologies:

- Dry cutting: No cutting fluid used

- MQL technology: Minimum quantity lubrication

- Cryogenic cutting: Using liquid nitrogen cooling

- Chip recycling: Realizing material recycling

- Energy-saving equipment: Reducing energy consumption

Environmental Benefits:

- Reduce cutting fluid emissions

- Reduce energy consumption

- Reduce waste generation

- Improve working environment

- Comply with environmental regulations

9. Conclusion

Custom CNC machining of aluminum parts plays an important role in modern manufacturing industry. By mastering key technologies and overcoming challenges, enterprises can better meet the custom needs of various industries for high-quality, high-precision aluminum parts.

Based on 15 years of actual machining experience and combined with a large amount of experimental data, this paper systematically introduces the technical points and application cases of custom CNC machining of aluminum parts. It is hoped to provide practical technical references for industry practitioners and promote technological progress and innovative development of the manufacturing industry.

In the future, with the development of intelligent, composite and green technologies, custom CNC machining technology for aluminum parts will usher in new development opportunities and provide strong support for the transformation and upgrading of the manufacturing industry.

References

- “Metal Cutting Principles and Tools”, Machinery Industry Press, 2024

- “CNC Machining Process Manual”, Machinery Industry Press, 2023

- “Aluminum Alloy Materials and Applications”, Metallurgical Industry Press, 2022

- ISO 9001:2015 Quality Management System Standard

- GB/T 19001-2016 Quality Management System Requirements

Author Contact Information

Name: Engineer Li

Professional Field: CNC Precision Machining Technology

Experience: 15 years of CNC machining process research and application experience

Research Direction: Aluminum alloy precision machining, process optimization, intelligent machining technology