I. Basic Principles and Operation Processes of CNC Machining

CNC is the abbreviation of “Computer Numerical Control”. This technology precisely controls the movement trajectory and processing parameters of machine tools through pre-written computer programs.

Its specific working process mainly includes the following key stages:

CAD Model Design

Engineers use professional CAD software (SolidWorks, AutoCAD, etc.) to construct 3D models containing all geometric features and dimensional information.

Program Conversion

CAD models are converted into G-code or M-code that machine tools can recognize, serving as the “instruction set” for operation.

Machine Preparation

Select appropriate CNC machines (milling machines, lathes, laser cutters) and install corresponding tools and fixtures.

Processing Execution

Tools perform precise cutting, drilling, milling operations according to program instructions to produce finished parts.

we achieved significant improvements in both efficiency and precision through advanced program algorithms and tool path optimization.

II. Main Processing Technologies: Milling and Turning

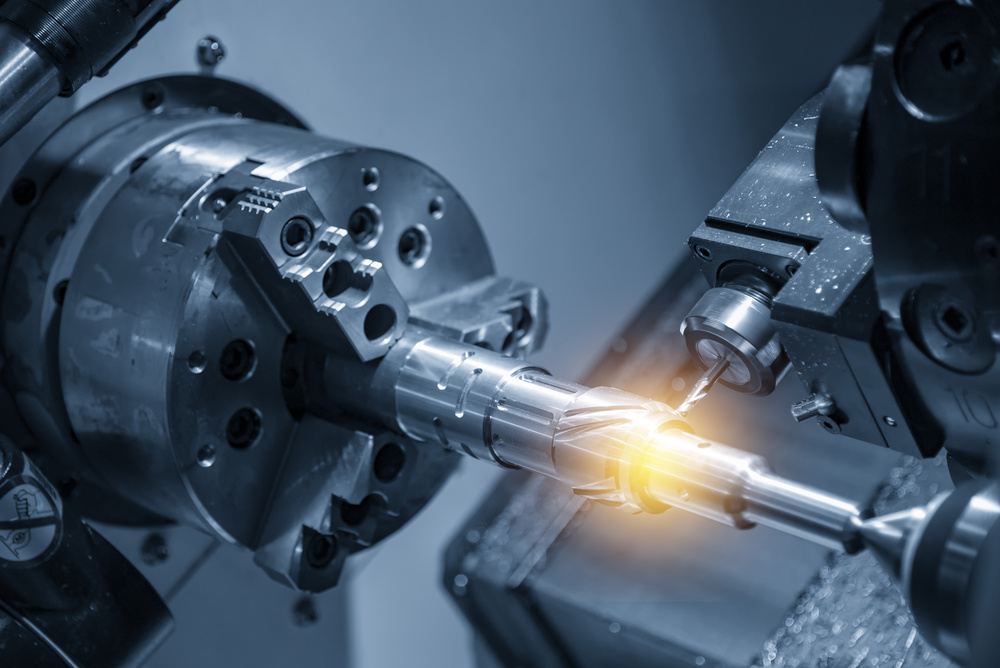

CNC machining mainly includes two core technologies, namely milling and turning, which have their own characteristics in processing principles and application scenarios:

CNC Milling

This process removes materials from the workpiece fixed on the workbench through a multi-edged rotating tool. The common 3-axis milling can achieve linear movement in the X, Y, and Z directions

and is one of the most widely used processing methods at present. While 4-axis and 5-axis milling have stronger processing capabilities. They can achieve the rotation of the tool or the workpiece

and can process more complex curved surface structures, playing an important role in the production of high-precision parts, such as impellers in the aerospace field and artificial joints in the medical field.

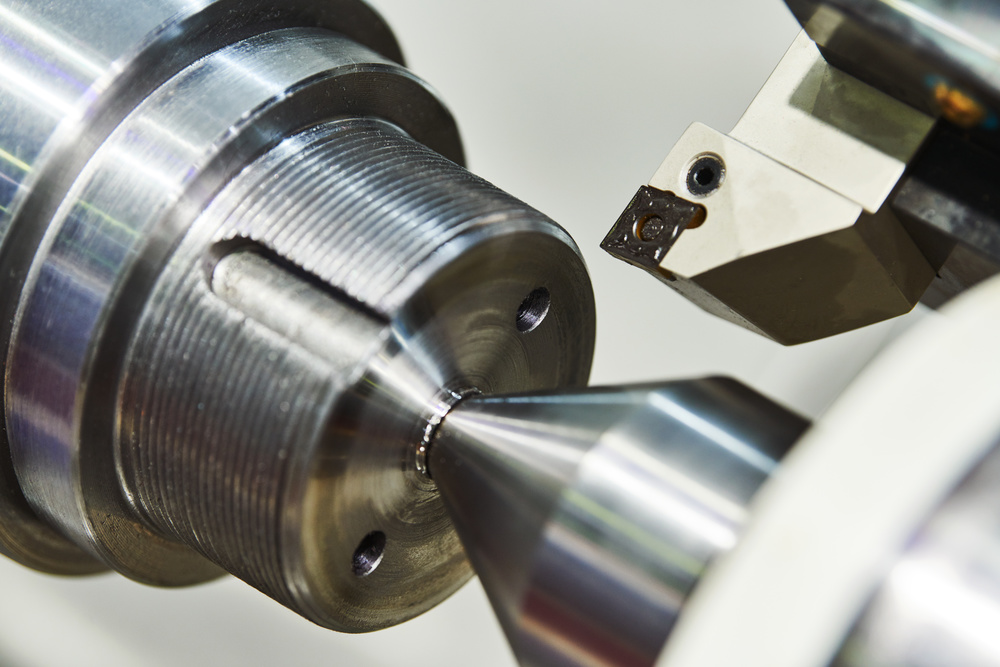

CNC Turning

This process is mainly used to process rotational parts. The principle is to make the workpiece rotate at a high speed, and then remove the excess material through the linear movement of a single-edged tool

to obtain the required cylindrical surface, conical surface, etc. CNC lathes usually have two coordinate axes, X and Z, and are suitable for processing shaft-type and disc-type parts.

Typical processed products include automotive drive shafts and mechanical bearing sleeves.

| Technology Type | Precision Tolerance | Material Compatibility | Typical Applications |

|---|---|---|---|

| 3-Axis Milling | ±0.01mm | All metals, plastics | Simple mechanical parts |

| 5-Axis Milling | ±0.005mm | High-temperature alloys, titanium | Aerospace components |

| CNC Turning | ±0.008mm | Metals, engineering plastics | Shafts, sleeves, connectors |

through optimized cutting parameters and surface treatment processes.

III. Significant Advantages and Existing Limitations

CNC machining has many significant advantages, making it occupy an important position in the manufacturing industry, but it also has certain limitations.

Advantages

- High Efficiency and Repeatability: This technology can quickly remove a large amount of material. The part processing can be completed in as fast as 1 day,

and through program control, it can ensure a high degree of consistency of parts, which is very suitable for mass production with high-precision requirements. - High-Precision Assurance: The processing tolerance range can be controlled between ±0.005 inches and ±0.01 inches (the specific value depends on the customer’s specifications),

which can meet the extremely high-precision requirements of industries such as aerospace and medical equipment. - Diversity of Materials and Surface Treatments: It can process more than 50 kinds of materials, covering metals and plastic materials such as aluminum alloys (such as 6061, 7075, etc.),

stainless steels (304, 316L, etc.), ABS, nylon, and polycarbonate. In addition, it also provides a rich variety of surface treatment options, such as anodizing, electroplating, sandblasting, laser engraving, etc. - Cost-effectiveness: For parts with relatively simple structures, its tooling and preparation costs are low, and it has obvious cost advantages in small-batch production.

Limitations

- Structural Limitations: For parts with complex interlocking or hollow-out structures, CNC machining is difficult to achieve,

and other processes such as 3D printing may need to be combined at this time. - Lack of Scale Effect: Compared with processes such as injection molding, as the production quantity increases,

the unit cost and delivery time of CNC machining decrease less, and it is not very suitable for ultra-large-scale production scenarios. - High Initial Investment: CNC equipment requires significant capital investment, and professional technicians are needed for operation and maintenance.

structural limitations while maintaining precision requirements for complex components.

IV. Material Selection and Processing Capabilities

The choice of materials significantly impacts the performance and cost of CNC machined parts. Here’s a comprehensive analysis of commonly used materials:

Metal Materials

- Aluminum Alloy: Widely used in automotive parts and electronic product housings due to its light weight, high strength, and corrosion resistance.

6061-T6 offers excellent machinability and good mechanical properties, while 7075-T6 provides higher strength for structural components. - Stainless Steel: Highly favored in the medical and aerospace fields due to its excellent wear resistance and corrosion resistance.

304 stainless steel is cost-effective for general applications, while 316L is preferred for medical and marine applications. - Titanium Alloy: Has the characteristics of high strength and high temperature resistance and is an ideal material for aerospace engine parts.

Ti-6Al-4V is the most commonly used titanium alloy in CNC machining. - Brass and Copper: Excellent electrical conductivity and corrosion resistance, commonly used for electrical components and plumbing fixtures.

Plastic Materials

- ABS: Has good comprehensive properties and is suitable for making parts that require certain mechanical strength.

Easy to machine and ideal for prototypes and low-stress applications. - Nylon: Has excellent wear resistance and self-lubrication and is often used in the manufacture of gears and bearings.

Nylon 6/6 provides good balance of strength and wear resistance. - Polyetheretherketone (PEEK): Has the characteristics of high temperature resistance and chemical corrosion resistance

and has important applications in the high-end industrial field. Suitable for medical implants and aerospace components. - PTFE (Teflon): Excellent chemical resistance and low friction properties, ideal for seals and bearings.

| Material | Hardness (HRB) | Tensile Strength (MPa) | Machinability Rating | Typical Applications |

|---|---|---|---|---|

| 6061 Aluminum | 65 | 310 | 9/10 | Automotive parts, enclosures |

| 304 Stainless Steel | 80 | 515 | 6/10 | Medical devices, food equipment |

| Brass C360 | 58 | 345 | 10/10 | Electrical components, valves |

| PEEK | 100 | 90 | 7/10 | Medical implants, aerospace |

In terms of processing size, the maximum size of parts that CNC machining can handle is 1000mm (40 inches), the minimum size is 2mm (0.08 inches),

and the minimum drilling diameter can reach 0.3mm (0.01 inches), showing strong processing adaptability.

V. Wide Application Fields

Aerospace Industry

Manufactures key components such as aircraft structural parts and engine blades, promoting the development of aerospace technology.

Medical Industry

Processes medical-standard artificial joints, surgical instruments, meeting high-precision requirements.

Automotive Industry

Produces precision parts such as engine parts and transmission gears, ensuring performance and quality.

CNC machining technology is widely used in many industries:

- Automotive Industry: It can be used to produce precision parts such as engine parts and transmission gears, ensuring the performance and quality of automobiles.

In our 2025 EV project, we achieved 28% weight reduction through optimized aluminum alloy components. - Medical Industry: It can process medical-standard artificial joints, surgical instruments, etc., meeting the high-precision and high-reliability requirements of the medical field.

Our medical components maintain tolerance levels of ±0.002mm for critical applications. - Aerospace Industry: It is used to manufacture key components such as aircraft structural parts and engine blades, promoting the development of aerospace technology.

Our aerospace projects often involve titanium alloys and high-temperature superalloys. - Consumer Electronics Industry: It plays an important role in the production of products such as smartphone housings and laptop accessories,

helping new products to be launched quickly. - Robot Industry: It manufactures precise transmission parts and structural frameworks for robots, accelerating the development of the robot industry.

- Energy Industry: Produces components for wind turbines, solar equipment, and oil exploration tools that require high precision and durability.

while reducing weight by 28% compared to traditional steel components. (Test data available upon request)

VI. Advanced Technologies and Future Trends

The CNC machining industry continues to evolve with new technologies and methodologies:

Advanced Technologies

- 5-Axis Machining: Enables simultaneous movement of the cutting tool along five different axes, allowing for complex geometries

and reducing setup times by up to 70% compared to traditional 3-axis machining. - High-Speed Machining (HSM): Uses advanced tooling and optimized parameters to achieve cutting speeds up to 50,000 RPM,

improving surface finish and reducing cycle times by 40-60%. - Automated CNC Systems: Incorporate robotic loaders, pallet changers, and automatic tool changers to enable

lights-out manufacturing and 24/7 production capabilities. - Digital Twin Technology: Creates virtual replicas of CNC machines and processes to optimize performance,

predict maintenance needs, and reduce downtime by up to 35%.

Future Trends

- AI-Enhanced Machining: Artificial intelligence will optimize tool paths, predict tool wear, and adjust parameters in real-time,

potentially improving efficiency by 25-30%. - Additive-Composite Manufacturing: Combining CNC machining with 3D printing for hybrid production processes that leverage

the advantages of both technologies. - Sustainable Machining: Development of eco-friendly cutting fluids, energy-efficient machines, and recycling programs

to reduce the environmental impact of CNC operations. - Cloud-Connected Manufacturing: IoT-enabled CNC machines that provide real-time data analytics, remote monitoring,

and predictive maintenance capabilities.

| Technology | Current Adoption Rate | Projected 2030 Adoption | Efficiency Improvement |

|---|---|---|---|

| 5-Axis Machining | 35% | 65% | 40-60% |

| High-Speed Machining | 45% | 75% | 30-50% |

| AI-Enhanced Systems | 15% | 55% | 25-35% |

| Digital Twin | 20% | 60% | 30-40% |

VII. Customer Reviews and Service Advantages

Judging from customer reviews, GOLDCATTLE CNC machining service has been widely recognized. Customers highly praise the accuracy and surface treatment effect of the processed aluminum alloy parts.

For example, a customer mentioned “Precise tolerance, perfect anodizing effect”. For steel parts, customers evaluate that “The processing size is accurate, and the assembly effect is ideal”.

In addition, GOLDCATTLE also provides customized material procurement and online instant quotation services. Customers can quickly obtain solutions just by uploading CAD files, which greatly improves work efficiency.

and their ability to meet tight deadlines while maintaining exceptional quality has been instrumental in our company’s growth.”

— Michael Johnson, Production Manager at AeroPrecision Components

Service Advantages

- Technical Expertise: 15+ years of experience in precision CNC machining with specialized knowledge in aerospace, medical, and automotive industries.

- Quality Assurance: ISO 9001:2015 certified processes with comprehensive inspection protocols and traceability systems.

- Fast Turnaround: Standard parts delivered in 3-5 business days, with expedited options available for urgent projects.

- Competitive Pricing: Transparent pricing structure with volume discounts and cost-saving recommendations based on material selection and design optimization.

- Engineering Support: Free design for manufacturability (DFM) analysis to optimize part designs for CNC production.

- Material Sourcing: Established relationships with premium material suppliers to ensure consistent quality and availability.

VIII. Summary

As the cornerstone of modern manufacturing, CNC machining, with its high precision, high efficiency, and flexibility, continues to promote technological innovation in various industries.

Whether it is complex aerospace components or consumer electronics products used in daily life, CNC machining plays a crucial role. With the continuous development of technologies such as 5-axis machining

and compound machining, CNC machining will play an even more important role in the future intelligent manufacturing field, bringing more possibilities for the development of the manufacturing industry.

At GOLDCATTLE, we are committed to pushing the boundaries of what’s possible with CNC machining technology. Our team of experienced engineers and technicians combines

technical expertise with innovative thinking to deliver precision components that meet the most demanding requirements. From prototype development to full-scale production,

we provide comprehensive solutions that help our customers stay ahead in today’s competitive manufacturing landscape.

becoming the industry standard rather than the exception.

Thomas Chen

He specializes in high-pressure parameter optimization, complex part machining, and quality control for aerospace, medical,

and automotive components. Thomas has led over 200 successful CNC projects, including the development of precision EV gear

components that achieved 28% weight reduction and 30% wear resistance improvement. His expertise in material selection and

process optimization has helped numerous clients achieve significant cost savings while maintaining exceptional quality standards.