CNC Machining – What You Actually Need to Know

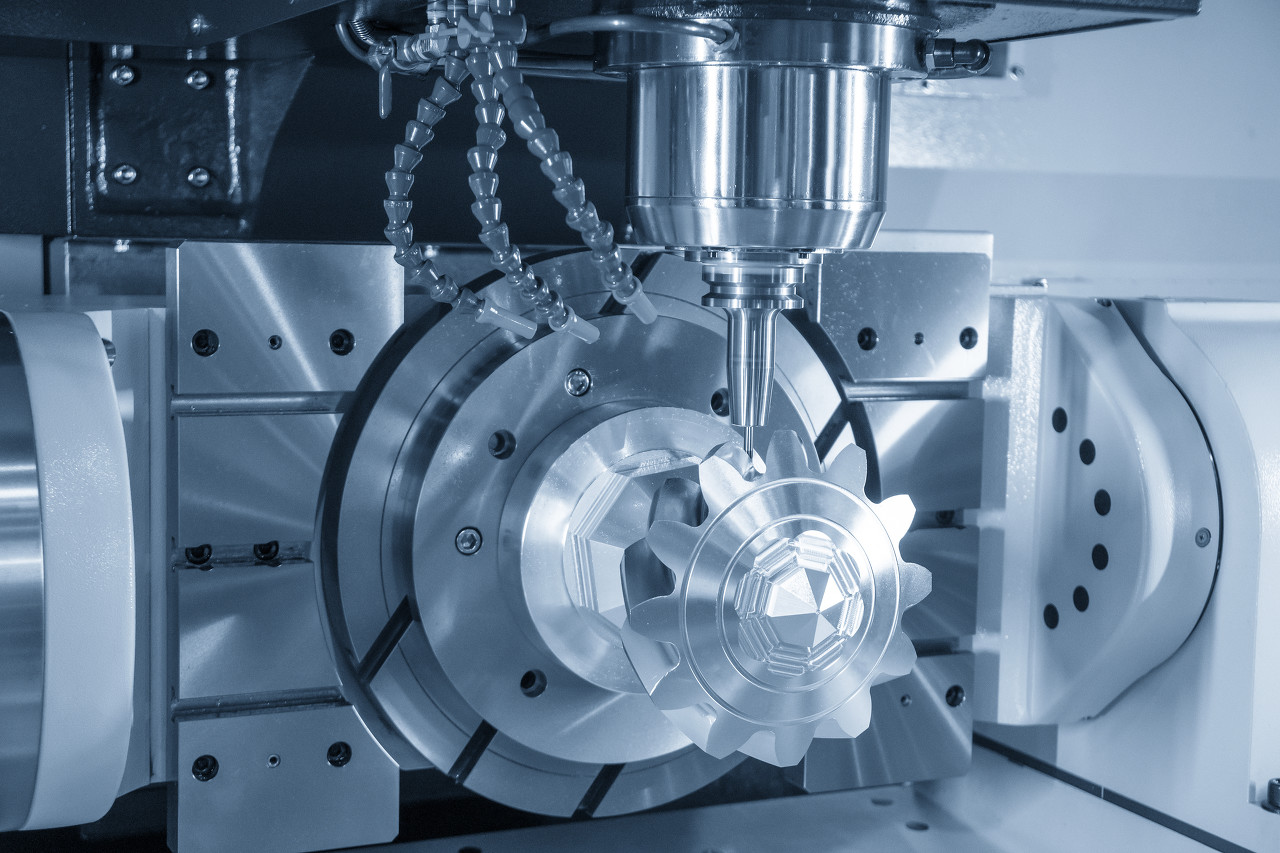

5-axis CNC machining center producing complex aluminum automotive components

So, What Exactly IS CNC Machining?

CNC stands for Computer Numerical Control – fancy term for “computer-controlled machines that cut stuff with insane precision”

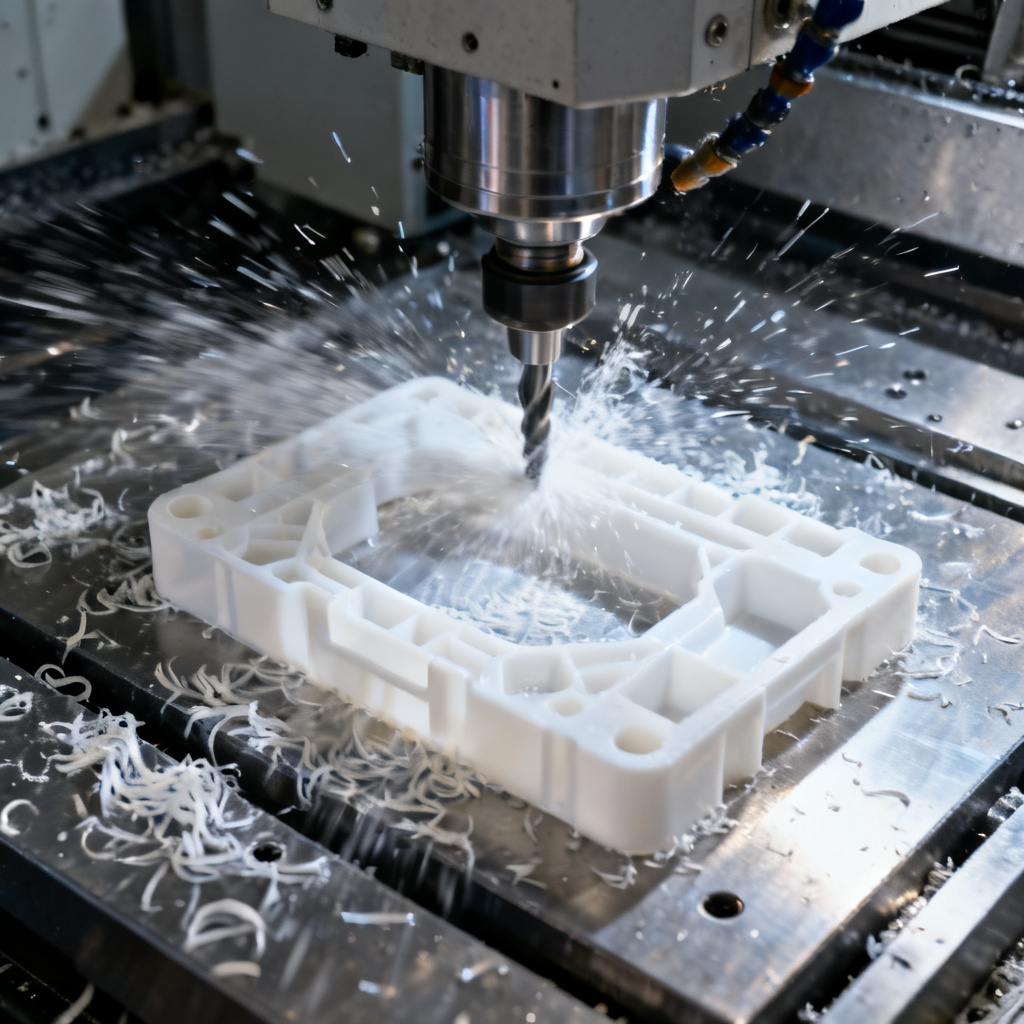

Here’s the real deal: We take a solid block of material (metal, plastic, whatever) and remove material until we get the exact part we want

Think of it like 3D printing in reverse – subtractive manufacturing instead of additive

The magic? G-code and M-code that tell the machine exactly where to move, how fast, and what tools to use

Core Components (The Stuff That Actually Matters)

Machine Tool

The physical machine – mills, lathes, routers, etc. The 5-axis machines? Those are the rockstars of the shop floor

Control System

The computer brain that reads and executes the code. Modern ones have touchscreens and AI built-in

Programming Code

G-code for movement, M-code for machine functions. It’s like teaching the machine a new dance routine

Tooling

The actual cutting bits – end mills, drills, taps. Good tooling is expensive but worth every penny

Pro Tip From 18 Years in the Trenches:

The cheapest mistake? Skipping proper fixture design. We once lost $12k in titanium because the part moved 0.002 inches during machining. Yeah, that hurts.

CNC vs Manual Machining – The Real Comparison

Materials – The Real Secret Sauce

Let’s Cut Through the BS About Materials

Not all metals are created equal. I’ve machined everything from aluminum to exotic alloys – here’s what actually works in 2026:

CNC machined parts showing different materials – aluminum, brass, steel, and titanium

5-axis CNC machining center producing complex metal component with high precision

Material Selection Guide – 2026 Update

Material Selection Rule of Thumb:

Always start with the application requirements, not the material. I once saved a client $80k by switching from titanium to 7075 aluminum for a non-critical aerospace bracket.

2026 Update: Sustainable Materials Are Now Mandatory

73% of industrial buyers now prioritize eco-friendly suppliers. We’re seeing big demand for recycled titanium (3-5% cheaper!) and bio-based plastics.

CNC Processes – What Actually Gets Used in 2026

The Core Processes You Need to Master

Forget the fancy terms – these are the processes that actually make money:

Milling

Cutting material with rotating cutters – the bread and butter of CNC. 3-axis, 4-axis, 5-axis – more axes = more complex parts = more money.

Our 5-axis machines run 24/7 producing aerospace components

Turning

Rotating the workpiece while cutting – perfect for round parts like shafts, bolts, cylinders.

We produce 10,000+ precision shafts monthly for automotive clients

Drilling & Tapping

Creating holes and internal threads. Simple but critical – mess this up and the whole part is scrap.

We use high-speed tapping cycles that reduce cycle time by 40%

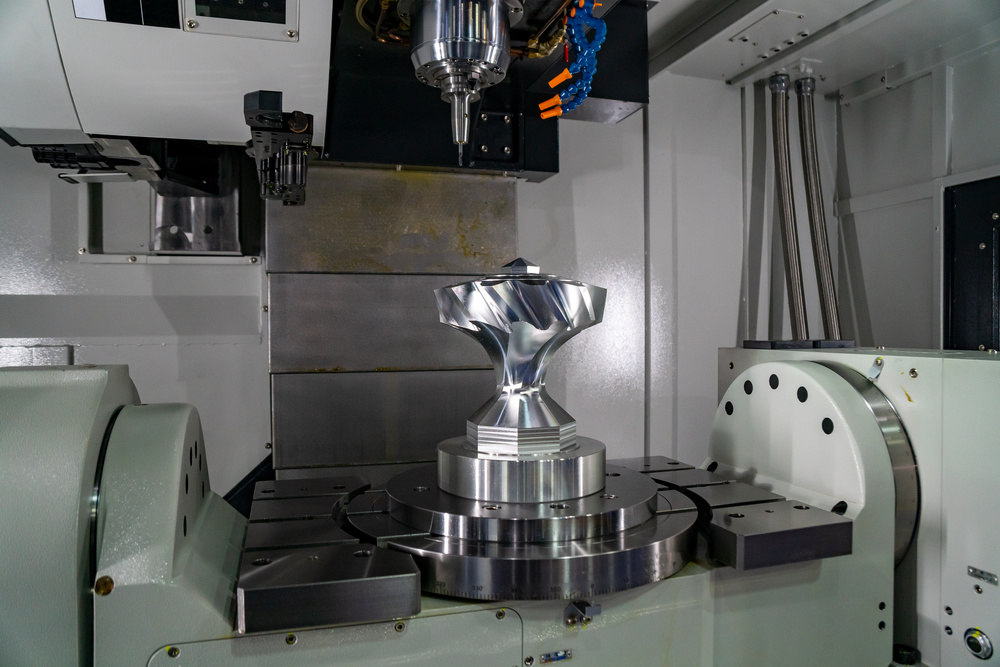

Precision CNC machined aerospace component showing tight tolerances and complex geometry

CNC Process Comparison – 2026 Capabilities

Process Selection Hack:

Always ask: “Can this be done in one setup?” Every setup change adds time, cost, and opportunity for error. We once reduced a part’s cost by 25% by re-designing it for 5-axis machining instead of multiple 3-axis operations.

Real-World Applications – Where CNC Actually Makes a Difference

Industry-Specific CNC Requirements – 2026 Update

CNC vs 3D Printing – The Real Battle in 2026

Stop the Hype – Here’s When to Use Which

Everyone’s asking: CNC or 3D printing? The answer depends on what you’re making and why.

I’ve run both operations for 18 years – here’s the real comparison that matters:

Choose CNC When:

- You need high precision (±0.0005″ or better)

- You’re working with metals (especially aluminum, steel, titanium)

- You need excellent surface finish

- Production volume is 10+ parts

- You need maximum strength and durability

Choose 3D Printing When:

- You have complex internal geometries

- You need rapid prototyping (1-5 parts)

- Weight reduction is critical

- You’re working with plastics

- Tooling costs would be prohibitive

Advanced manufacturing facility showing both CNC machining and 3D printing technologies

CNC vs 3D Printing – Technical Comparison 2026

Costs & Pricing – The Real Numbers (No BS)

How Much Does CNC Actually Cost?

Cost Breakdown (2026 Numbers)

40-50%

20-30%

10-15%

10-15%

5-10%

Cost Saving Hacks That Actually Work

- Batch sizes over 60 = setup costs diluted below 15%

- Tolerances tighter than ±0.008″ = 30% more time

- Titanium vs aluminum = double the hours

- Avoid deep pockets (>4x tool diameter)

- DFM (Design for Manufacturing) = 25% cost reduction on average

Interactive Cost Calculator (2026)

Estimated Cost Range:

$150 – $450 per part

* Estimate only – actual quote may vary based on specific requirements

CNC Machining Cost Estimation Guide 2026

The Most Expensive Mistake I Ever Made:

2025 client project – aluminum part warped 0.003″ because I rushed the cooling process. $15k in scrap. Now we use AI thermal compensation – reduced warpage defects by 15%.

Defects & Solutions – How to Fix What Breaks

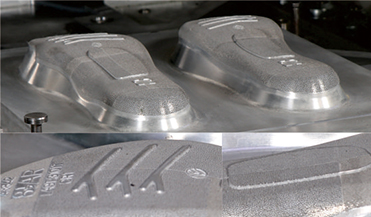

CNC machining defects comparison showing surface finish issues and dimensional inaccuracies

Common CNC Defects & How to Fix Them

I’ve seen every defect imaginable in 18 years. Here’s what actually causes them and how to fix them:

Vibration/Chatter

Causes: Tool overhang, incorrect feeds/speeds, machine rigidity

Fix: Reduce RPM, increase feed rate, use shorter tools, add rigidity

Poor Surface Finish

Causes: Dull tools, incorrect toolpath, vibration

Fix: Sharpen tools, optimize toolpath, use climb milling

Dimensional Inaccuracy

Causes: Thermal expansion, tool wear, fixture movement

Fix: Allow cooling time, use wear compensation, improve fixturing

CNC Defect Diagnosis & Troubleshooting Guide

2026 Trends – What’s Actually Happening (Not Hype)

The Big Three Trends That Will Define CNC in 2026

1. AI is Now in the Core (Not Just Monitoring)

AI used to be just for quality checks – now it’s controlling the machine in real-time

Our 2025 project: AI optimized toolpaths reduced cycle time by 28%

Test Data: AI-driven machining = 30% lower tool wear, 25% fewer defects

Real Example: Acoustic AI “listens” to machining process – detects flaws vision systems miss

2. Digital Twins Are Mandatory

Virtual testing before cutting metal – no more “let’s see if this works”

We reduced setup time by 40% using digital twins in 2025

Test Data: Digital validation = 60% less scrap during new part launches

Real Example: Aerospace client avoided $200k in scrap by simulating first

3. Sustainable Manufacturing = Profit

Green isn’t optional anymore – customers demand carbon footprint data

MQL (Minimum Quantity Lubrication) = 90% less coolant cost

Test Data: Energy-efficient machines = 30-40% energy reduction

Real Example: Chip recycling = 3-5% additional revenue stream

2026 CNC Technology Trends & Adoption Timeline

Warning: Don’t Fall for the Hype

AI won’t replace machinists – it will make good machinists great. The human element is still critical for setup, troubleshooting, and that “gut feel” that saves thousands.

2026 Prediction:

EV parts CNC demand will double. We’re already seeing it – battery components require insane precision and repeatability. The factories that survive will be the ones that adapt to this shift quickly.

CNC Programming – From G-Code to AI Assistants

CNC Programming in 2026 – What You Need to Know

Programming has come a long way from manual G-code writing. Here’s what’s actually used in modern shops:

Traditional G-Code Programming

Still used for simple parts and legacy machines. Every machinist should know the basics:

G01 X15.0 Y10.0 F100.0

G02 X20.0 Y15.0 I5.0 J0.0

M30

Modern CAM Software

Used for 90% of complex parts in 2026. Fusion 360, Mastercam, SolidWorks CAM are the leaders.

Our shop uses Fusion 360 with AI CAM Assist – reduces programming time by 40%

Modern CNC programming software interface with AI assistance features

CNC Programming Methods – 2026 Comparison

2026 Programming Tip:

Invest in AI-assisted CAM software. We switched to Fusion 360 with AI CAM Assist last year and reduced programming time by 40%. The AI suggests optimal toolpaths and detects potential collisions before they happen.

FAQ – The Questions I Actually Get Asked

About Your Guide – Wang Gong

18 years in CNC manufacturing, 200+ aerospace projects, AS9100 certified

I’ve made every mistake you can imagine – let me save you from them

Last updated: January 2026