CNC prototype machining has emerged as a revolutionary technique in the field of manufacturing, enabling the creation of precise and functional prototypes with remarkable speed and accuracy.

CNC, or Computer Numerical Control, refers to the process where machines are controlled by a pre-programmed set of instructions. In the context of prototype machining, this technology offers several distinct advantages.

One of the key benefits is the high level of precision it achieves. With tolerances often measured in microns, CNC prototype machining ensures that the final product closely adheres to the design specifications. This level of accuracy is crucial when developing prototypes, as it allows for a thorough evaluation of the design’s functionality and form.

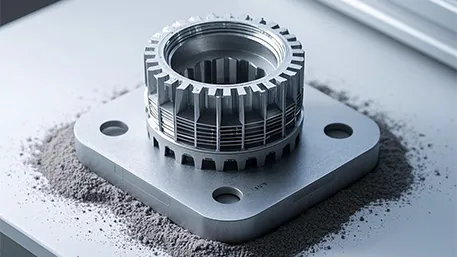

The materials used in CNC prototype machining are diverse, ranging from metals like aluminum, steel, and titanium to plastics and composites. The choice of material depends on the specific requirements of the prototype, such as strength, durability, and aesthetic properties.

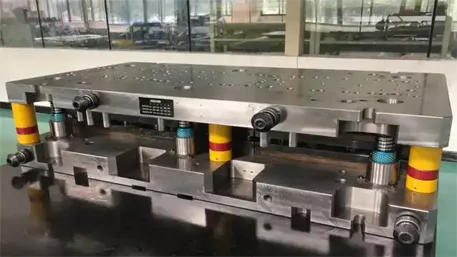

The process also allows for complex geometries and intricate designs to be realized with ease. Whether it’s a curved surface, a detailed internal structure, or a multi-component assembly, CNC machining can handle it all.

Another significant aspect is the speed at which prototypes can be produced. Compared to traditional manufacturing methods, CNC machining significantly reduces the lead time, allowing for quicker iterations and improvements in the design process.

Programming plays a vital role in CNC prototype machining. Skilled programmers use specialized software to create the toolpaths and instructions that guide the machine’s movements. They take into account factors such as cutting speed, feed rate, and depth of cut to optimize the machining process and ensure quality results.

CNC prototype machining finds applications in a wide range of industries. In the aerospace sector, it helps create prototypes for aircraft components to test their performance and fit. In the automotive industry, it enables the development of prototype parts for new vehicle models. The medical field also benefits from this technology for creating prototypes of medical devices and implants.

In conclusion, CNC prototype machining has transformed the way prototypes are developed, offering a combination of precision, speed, and design flexibility that is essential in today’s competitive manufacturing landscape.