Implementation Guidelines and Best Practices

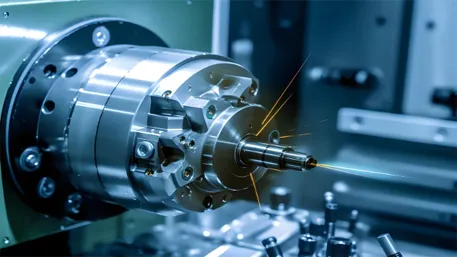

Equipment Requirements

To effectively implement contour line machining:

- CNC System: Modern controller with look-ahead capability (minimum 100 blocks)

- Machine Rigidity: High stiffness to minimize vibration

- Spindle Performance: Adequate power and speed range

- Tool Holders: Precision holders with low runout (<0.003mm)

- Measurement System: Tool length and workpiece probing

Programming Parameters

Key parameters for successful contour line programming:

1. Layer Height Selection

- Finishing operations: 0.05-0.2mm per layer

- Semi-finishing: 0.2-0.5mm per layer

- Roughing: 0.5-2.0mm per layer (depending on material and tool)

2. Stepover Distance

- General rule: 10-50% of tool diameter

- Finishing: 10-25% for Ra < 1.6 μm

- Roughing: 30-50% for maximum efficiency

3. Cutting Parameters

- Feed rate: 50-200 mm/min for finishing, 200-1000 mm/min for roughing

- Spindle speed: Based on tool material and workpiece material

- Coolant: Essential for maintaining tool life and surface quality

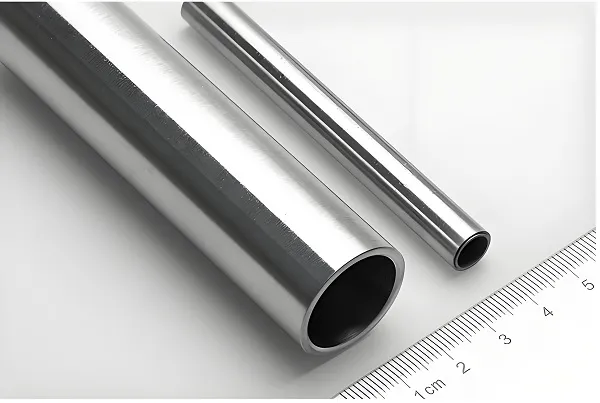

Tool Selection

The right tool selection is critical:

- End mills: Most common for contour line machining

-

- Square end mills: For sharp corners and flat areas

-

- Ball nose end mills: For complex curved surfaces

-

- Corner radius end mills: For increased tool life

-

- Carbide: Best for most applications

-

- HSS-E: For low-volume or non-ferrous materials

-

- Cermet: For high-speed machining of steels

Advanced Techniques and Innovations

5-Axis Contour Machining

The integration of 5-axis machining with contour lines offers significant advantages:

- Improved tool access: Reach complex undercuts and deep cavities

- Optimized tool orientation: Maintain optimal cutting angles

- Reduced setup time: Complete machining in fewer operations

- Enhanced surface quality: Eliminate tool marks from varying angles

AI-Driven Optimization

Modern systems incorporate artificial intelligence:

- Adaptive stepover: AI algorithms adjust stepover based on real-time feedback

- Tool wear prediction: Machine learning models predict optimal tool replacement

- Process optimization: Continuous improvement based on historical data

Hybrid Machining Strategies

Combining contour lines with other strategies:

- Contour-parallel roughing + contour lines finishing

- Adaptive clearing + contour lines semi-finishing

- Pocketing + contour lines for vertical walls

Quality Control and Verification

In-Process Monitoring

Implementing effective monitoring systems:

- Force sensing: Detecting tool deflection and breakage

- Vibration analysis: Monitoring spindle and workpiece vibrations

- Acoustic emission: Detecting tool wear and material changes

- Vision systems: Real-time surface quality inspection

Post-Process Inspection

Essential inspection techniques:

- Coordinate Measuring Machines (CMM): Verifying dimensional accuracy

- Surface profilometers: Measuring surface roughness and texture

- Optical scanners: Comparing actual vs. nominal geometry

- Sectional analysis: Checking contour line accuracy at specific Z-heights

Future Trends in Contour Line Machining

Industry 4.0 Integration

The future of contour line machining will be shaped by:

- Digital twins: Virtual simulation of the entire machining process

- Cyber-physical systems: Real-time data exchange between machines

- Cloud-based programming: Remote programming and monitoring

- Additive-subtractive hybrid: Combining 3D printing with contour machining

Sustainability Improvements

Environmental considerations are becoming increasingly important:

- Energy optimization: Minimizing energy consumption during contour machining

- Coolant reduction: Developing dry and minimum quantity lubrication techniques

- Tool material innovation: Longer-lasting, recyclable tool materials

- Process optimization: Reducing material waste through precise contour control

Conclusion

CNC milling contour lines represent a sophisticated machining strategy that enables the precise and efficient production of complex 3D components. By breaking down surfaces into manageable horizontal layers, this technique provides exceptional accuracy, surface quality, and process reliability.

As manufacturing technology continues to advance, contour line machining will remain a cornerstone of precision manufacturing. Its integration with AI, 5-axis machining, and Industry 4.0 technologies will further enhance its capabilities and expand its applications.

For manufacturing professionals, mastering contour line machining is essential for staying competitive in today’s precision-driven industries. By understanding its principles, implementing best practices, and leveraging the latest technological innovations, organizations can achieve significant improvements in quality, efficiency, and profitability.