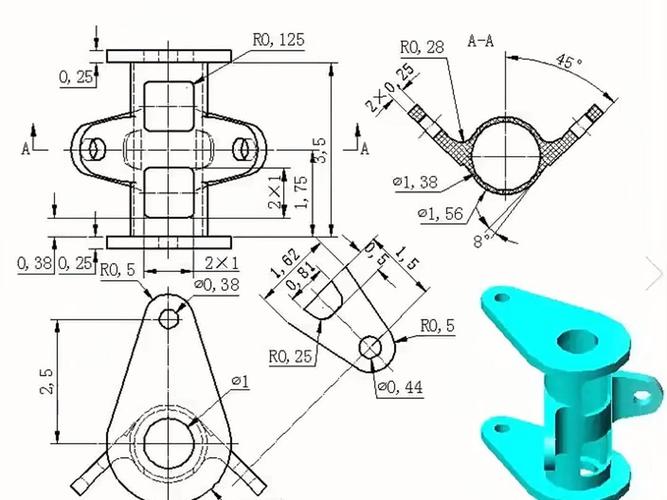

1. Step 1: Design & CAM Programming — Lay the Precision Foundation

(1) 3D Model Design

- Purpose: Create a parametric 3D model of the part, defining critical features (holes, grooves, curved surfaces) and tolerances (e.g., ±0.005 mm for aerospace parts).

- Key Tools: CAD software (SolidWorks, UG NX, AutoCAD); for complex free-form surfaces (e.g., turbine blades), use NURBS (Non-Uniform Rational B-Splines) modeling to ensure contour accuracy (error ≤0.001 mm).

- Technical Notes:

-

- Avoid sharp internal corners (radius ≥0.2 mm) — sharp corners cause tool tip stress concentration (≥500 MPa) and accelerate wear.

-

- For thin-walled parts (thickness ≤1 mm), add temporary support structures (e.g., 0.5 mm thick ribs) to prevent machining deformation.

(2) CAM Programming (Tool Path Generation)

- Purpose: Convert the 3D model into G-code (machine language) by defining cutting parameters, tool selection, and path strategy.

- Key Tools: CAM software (Mastercam, Siemens NX CAM, Fusion 360); advanced systems support “feature-based programming” (auto-selects parameters for holes/grooves).

- Critical Parameters & Choices:

|

Parameter

|

Definition

|

Selection Criteria (Example)

|

|

Tool Path Type

|

Path of tool relative to workpiece

|

– Cavity milling: For deep pockets (depth ≥5× tool diameter);- Contour milling: For outer surfaces; – Helical milling: For hole drilling (avoids axial force).

|

|

Cutting Speed (V)

|

Speed of tool rotation (m/min)

|

Aluminum (6061): 150–300 m/min; Stainless steel (304): 50–100 m/min; Titanium (Ti-6Al-4V): 30–60 m/min.

|

|

Feed Rate (f)

|

Distance tool moves per revolution (mm/r)

|

Carbide end mill (φ10 mm): 0.1–0.2 mm/r (roughing); 0.05–0.08 mm/r (finishing).

|

|

Depth of Cut (aₚ)

|

Thickness of material removed per pass (mm)

|

Avoid single-pass heavy cuts: ≤2 mm for aluminum; ≤1 mm for stainless steel (prevents work hardening).

|

- Error Prevention: Use “G-code simulation” (e.g., in Vericut) to check for collisions (tool vs. fixture) or overcutting — 70% of machining failures originate from untested G-code.

2. Step 2: Material Preparation & Workpiece Clamping — Ensure Stability

(1) Material Preparation

- Purpose: Select and cut raw material to size, ensuring it meets mechanical properties (e.g., hardness, tensile strength) for milling.

- Key Operations:

-

- Material selection: Match alloy to part function (e.g., 316L stainless steel for corrosion-resistant medical parts; 7075 aluminum for high-strength aerospace brackets).

-

- Sizing: Use a bandsaw or laser cutter to cut raw stock to “blank size” — add 2–5 mm machining allowance (compensates for material loss and clamping).

- Quality Checks:

-

- For metal materials: Verify hardness (e.g., HB 150–200 for 6061 aluminum) with a Brinell tester — over-hardened material (HB ≥250) accelerates tool wear.

-

- For plastic materials (e.g., PEEK): Check for internal voids (via ultrasound) — voids cause tool chatter during milling.

(2) Workpiece Clamping

- Purpose: Fix the blank to the machine table with sufficient rigidity, minimizing movement during cutting.

- Fixture Selection & Technical Parameters:

|

Fixture Type

|

Application Scenario

|

Clamping Force (N)

|

Repeat Positioning Accuracy (mm)

|

|

Machine Vise

|

Small parts (≤100×100×100 mm, e.g., aluminum brackets)

|

50–200

|

≤0.005

|

|

Zero-Point System

|

High-volume parts (e.g., automotive sensors)

|

100–300

|

≤0.002

|

|

Custom Jigs

|

Irregular parts (e.g., turbine casings)

|

200–500

|

≤0.003

|

- Clamping Rules:

-

- Distribute clamping force evenly: Use 2–4 clamping points (avoid single-point clamping, which causes deformation).

-

- For thin-walled parts (thickness ≤1 mm): Use low clamping force (≤50 N) + flexible jaws (polyurethane-coated) to reduce ovality error (≤0.003 mm).

-

- Align the blank with the machine’s X/Y zero point: Use a edge finder (accuracy ±0.001 mm) to set the origin — misalignment ≥0.005 mm leads to dimensional overrun.

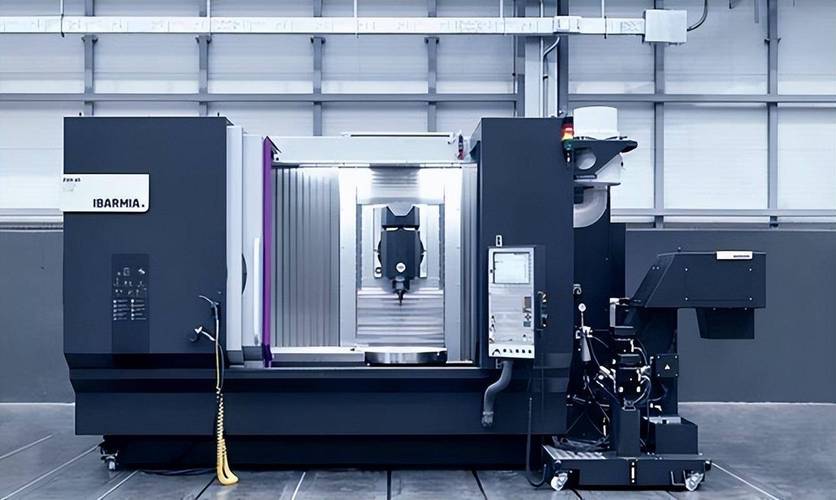

3. Step 3: Machine Setup & Tool Calibration — Achieve Micron-Level Precision

(1) Machine Setup

- Purpose: Prepare the CNC mill for operation, including spindle warm-up, coolant system activation, and axis homing.

- Key Operations:

-

- Spindle warm-up: Run the spindle at 50% of maximum speed (e.g., 5,000 rpm for a 10,000 rpm spindle) for 5–10 minutes — reduces thermal expansion (≤0.001 mm) during machining.

-

- Coolant system check: Ensure coolant type (synthetic for stainless steel, emulsion for aluminum) and pressure (3–5 MPa) match the material — low pressure (≤2 MPa) causes poor heat dissipation.

-

- Axis homing: Execute “G28” (return to reference point) to calibrate X/Y/Z axes — homing accuracy ≤0.0005 mm (critical for multi-axis milling).

(2) Tool Calibration

- Purpose: Measure tool dimensions (length, radius) and input them into the CNC system for accurate path calculation (avoids undercutting/overcutting).

- Calibration Tools & Accuracy:

|

Calibration Device

|

Measured Parameter

|

Accuracy (mm)

|

Application

|

|

Tool Presetter (Zoller V3)

|

Tool length, radius

|

≤0.0005

|

Offline calibration (high-volume production)

|

|

Touch Probe (Renishaw MP250)

|

Tool length, runout

|

≤0.001

|

Online calibration (small-batch parts)

|

- Critical Checks:

-

- Tool runout: Measure runout at the tool tip (≤0.002 mm) — excessive runout (≥0.005 mm) causes surface scratches (Ra ≥1.6 μm).

-

- Tool wear: For reused tools, check flank wear (VB ≤0.3 mm for carbide tools) — worn tools reduce dimensional accuracy by 0.005–0.01 mm.

- Data Input: Enter tool length (Z-offset) and radius (X-offset) into the CNC’s tool offset table (e.g., Fanuc 0i-MF’s G43/G41 commands) — incorrect offsets are the #1 cause of part scrapping.

4. Step 4: Test Cutting & Parameter Debugging — Validate Process Feasibility

(1) Test Cutting Execution

- Purpose: Machine a single “first article” (sample part) to validate G-code, tool performance, and clamping stability.

- Key Operations:

-

- Use a low-feed “air cut” first: Run the tool along the programmed path without cutting material — checks for collisions (tool vs. fixture) or path errors.

-

- Execute test cutting: Machine the sample with the programmed parameters, focusing on critical features (e.g., holes, threads, curved surfaces).

- Sample Selection: For batch production, use the same material and blank size as the final parts — different blanks (e.g., thicker material) lead to invalid parameter validation.

(2) Parameter Debugging

- Purpose: Adjust cutting parameters based on sample results to optimize precision and efficiency.

- Common Adjustments & Reasons:

|

Sample Issue

|

Root Cause

|

Parameter Adjustment

|

|

Surface Roughness Ra > 1.6 μm

|

Cutting speed too low (aluminum: <150 m/min)

|

Increase speed to 200–250 m/min; reduce feed rate to 0.05–0.08 mm/r.

|

|

Tool Chatter (Stainless Steel)

|

Tool rigidity insufficient; spindle speed resonant

|

Switch to a shorter tool (length-diameter ratio ≤5:1); adjust speed to 70–80 m/min (avoids resonance).

|

|

Dimensional Undercut (Holes)

|

Tool radius compensation too small

|

Increase tool radius offset by 0.001–0.002 mm; re-calibrate the touch probe.

|

- Validation Standard: The sample must meet 100% of design requirements (dimensional tolerance, surface roughness, geometric accuracy) before proceeding to batch processing.

5. Step 5: Batch Machining & In-Process Monitoring — Ensure Consistency

(1) Batch Machining Execution

- Purpose: Machine parts in batches, maintaining the same precision as the validated sample.

- Key Operations:

-

- Load/unload optimization: For high-volume parts, use automated systems (robotic arms, conveyor belts) to reduce downtime (from 2 minutes/part to 30 seconds/part).

-

- Tool change management: For long runs (≥100 parts), pre-stage backup tools (calibrated offline) — reduces tool change time (≤1 minute) and avoids parameter re-entry.

- Material-Specific Considerations:

-

- Aluminum (6061): Use high-pressure coolant (5 MPa) to flush chips — avoids chip re-cutting (causes surface burrs).

-

- Stainless steel (304): Implement intermittent cutting (pause 0.1s every 10mm) to reduce work hardening (hardness increase ≤10%).

-

- Titanium (Ti-6Al-4V): Use CBN tools (wear resistance 5× carbide) and cryogenic cooling (liquid nitrogen) — extends tool life to 60–90 minutes.

(2) In-Process Monitoring

- Purpose: Real-time detect anomalies (tool wear, workpiece movement) to prevent batch defects.

- Monitoring Technologies & Applications:

|

Monitoring Device

|

Measured Parameter

|

Threshold Value

|

Action When Exceeded

|

|

Vibration Sensor

|

Spindle vibration (mm/s)

|

≤0.1

|

Reduce feed rate by 10–15%; check tool runout.

|

|

Force Sensor

|

Cutting force (kN)

|

≤5 (aluminum); ≤8 (steel)

|

Pause machining; inspect tool for chipping.

|

|

Temperature Sensor

|

Cutting zone temp (°C)

|

≤300 (aluminum); ≤600 (steel)

|

Increase coolant flow rate by 20%.

|

- Data Integration: Connect sensors to the CNC system (e.g., Siemens Sinumerik One) for automated alerts — reduces manual inspection time by 50%.

6. Step 6: Post-Processing & Quality Inspection — Finalize Part Quality

(1) Post-Processing

- Purpose: Remove machining residues and improve part performance (e.g., corrosion resistance, fatigue strength).

- Common Operations:

-

- Deburring: Use a CNC deburring tool (φ1–3 mm) or ultrasonic cleaner to remove burrs (height ≤0.005 mm) — critical for medical parts (avoids tissue irritation).

-

- Surface Treatment:

-

-

- Aluminum: Anodizing (thickness 5–10 μm) — improves corrosion resistance (salt spray test ≥500 hours).

-

-

-

- Stainless steel: Passivation (20% nitric acid, 50°C) — rebuilds Cr₂O₃ oxide layer (meets ASTM A967).

-

-

-

- Titanium: Sandblasting (Ra 1.6–3.2 μm) — enhances bone integration for implants.

-

-

- Cleaning: Use isopropyl alcohol (for metals) or deionized water (for plastics) to remove coolant residue — prevents contamination (critical for food-contact parts).

(2) Quality Inspection

- Purpose: Verify that parts meet all design specifications, with 100% inspection for critical parts and sampling for high-volume parts.

- Inspection Tools & Standards:

|

Inspection Item

|

Tool Used

|

Accuracy (mm)

|

Industry Standard Example

|

|

Dimensional Accuracy

|

Coordinate Measuring Machine (CMM)

|

≤0.001

|

Aerospace: AS9100; Medical: ISO 13485

|

|

Surface Roughness

|

Contact Roughness Tester (Mitutoyo SJ-210)

|

≤0.001 μm

|

Ra ≤0.4 μm (medical implants)

|

|

Geometric Tolerance

|

Laser Scanner (Faro Focus S)

|

≤0.002

|

Flatness ≤0.01 mm/m (chemical flanges)

|

- Sampling Plan: For batches ≥100 parts, use AQL (Acceptable Quality Level) 1.0 (sample 80 parts, accept ≤2 defects) — balances inspection efficiency and quality.

7. Common Issues Across Steps & Troubleshooting

|

Step

|

Common Issue

|

Root Cause

|

Solution

|

|

Programming

|

Overcutting (Curved Surfaces)

|

Incorrect NURBS interpolation parameters

|

Adjust NURBS knot spacing (reduce to 0.5 mm); re-simulate G-code.

|

|

Clamping

|

Workpiece Deformation (Thin-Wall)

|

Clamping force too high (≥100 N)

|

Reduce force to 30–50 N; use vacuum clamping (for plastics).

|

|

Calibration

|

Tool Length Error (≥0.005 mm)

|

Touch probe dirty; temperature drift

|

Clean probe with alcohol; re-calibrate in a temperature-stabilized room (20±2°C).

|

|

Machining

|

Tool Breakage (Titanium)

|

Cutting speed too high (≥70 m/min); chip clogging

|

Reduce speed to 40–50 m/min; use internal-coolant tools (flow rate 30 L/min).

|

|

Inspection

|

Dimensional Variation (Batch)

|

Spindle thermal expansion (≥0.002 mm)

|

Add thermal compensation (G41/G42) to G-code; monitor spindle temp.

|

8. Future Trends in CNC Milling Steps

(1) Intelligent Step Optimization

- AI-Powered Programming: Machine learning models (e.g., in Autodesk Fusion 360) auto-select cutting parameters based on material and part geometry — reduces programming time by 40% and improves tool life by 25%.

- Digital Twins: Virtual replicas of the milling process (e.g., Siemens Opcenter) simulate all steps (design → machining → inspection) — predicts defects (e.g., tool chatter) before physical processing, reducing scrappage by 60%.

(2) Automated Step Integration

- Unmanned Production Lines: Robotic arms handle material loading/unloading, tool changing, and post-processing — 24/7 operation with 99.5% uptime (vs. 70% for manual lines).

- Inline Inspection: Integrate CMMs into the machining line (e.g., Zeiss inline sensors) — real-time data feedback adjusts parameters automatically (e.g., corrects tool wear mid-batch).

(3) Eco-Friendly Step Innovations

- Green Cooling: Replace traditional coolant with Minimum Quantity Lubrication (MQL) — uses 5–10 mL/h of vegetable oil (vs. 20–40 L/min coolant), reducing waste by 99%.

- Sustainable Post-Processing: Use water-based anodizing (instead of toxic chemicals) and recycled abrasives for sandblasting — cuts carbon footprint by 30%.