3D printing powder is a fine, homogeneous material designed for additive manufacturing (AM) processes that build parts layer-by-layer—such as Selective Laser Melting (SLM), Selective Laser Sintering (SLS), or Electron Beam Melting (EBM). Unlike filament (used in FDM printers), 3D printing powder relies on heat (laser/electron beam) to fuse particles into solid shapes, and its quality directly determines part density, strength, and surface finish.

Key requirements for high-performance 3D printing powder include:

- Uniform particle size (typically 15–100μm, depending on the process);

- Good flowability (to ensure even powder bed spreading);

- High purity (low impurities avoid part defects like porosity);

- Consistent chemical composition (for stable mechanical properties).

1. 3D Printing Powder Types: By Material & Application

3D printing powders are categorized by their base material, each tailored to specific 3D printing technologies and end-use scenarios. Below is a detailed breakdown of the most common types (with SEO-focused subheadings):

1.1 Metal 3D Printing Powder: For High-Strength Industrial Parts

Metal powders are the most widely used in industrial 3D printing, compatible with SLM, DMLS, and EBM technologies. They are prized for their strength, durability, and compatibility with high-performance applications.

| Powder Material | Particle Size Range | Suitable 3D Tech | Key Properties | Typical Applications |

|---|---|---|---|---|

| Titanium Alloy (Ti-6Al-4V) | 15–45μm | SLM, EBM | Low density (4.51g/cm³), high tensile strength (900MPa), biocompatible | Medical implants (hip joints), aerospace brackets |

| Stainless Steel (316L) | 20–53μm | SLM, DMLS | Corrosion-resistant, high ductility | Food machinery parts, marine components |

| Aluminum Alloy (AlSi10Mg) | 20–63μm | SLM | Lightweight (2.68g/cm³), good thermal conductivity | Automotive battery housings, electronics heat sinks |

| Nickel Superalloy (Inconel 718) | 15–53μm | SLM, DMLS | High-temperature resistance (up to 650°C) | Aerospace turbine blades, gas turbine components |

Focus: Metal 3D printing powder types, Ti-6Al-4V powder for SLM, stainless steel 316L 3D printing powder.

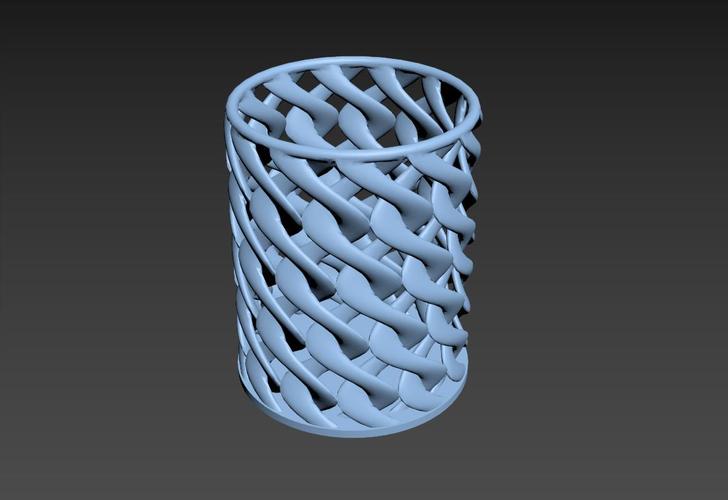

1.2 Plastic 3D Printing Powder: For Low-Cost Prototyping & Consumer Parts

Plastic powders are used in SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) technologies, offering low cost and flexibility for non-structural parts.

| Powder Material | Particle Size Range | Suitable 3D Tech | Key Properties | Typical Applications |

|---|---|---|---|---|

| Polyamide 12 (PA12) | 30–60μm | SLS, MJF | High impact resistance, low moisture absorption | Custom gears, cable organizers |

| Polyamide 11 (PA11) | 30–60μm | SLS | Biodegradable (made from castor oil), flexible | Medical device housings, athletic footwear components |

| Thermoplastic Elastomer (TPE) | 40–80μm | SLS | Rubber-like elasticity (Shore A 50–90) | Phone cases, grip handles |

Focus: SLS plastic 3D printing powder, PA12 powder for 3D printing, flexible TPE 3D powder.

1.3 Ceramic 3D Printing Powder: For High-Temperature & Chemical-Resistant Parts

Ceramic powders are compatible with SLM and binder jetting technologies, ideal for parts requiring extreme heat or chemical resistance.

| Powder Material | Particle Size Range | Suitable 3D Tech | Key Properties | Typical Applications |

|---|---|---|---|---|

| Alumina (Al₂O₃) | 20–50μm | Binder Jetting, SLM | High hardness (Mohs 9), heat resistance (up to 1700°C) | Industrial nozzles, electrical insulators |

| Zirconia (ZrO₂) | 15–40μm | Binder Jetting | High fracture toughness, biocompatible | Dental crowns, fuel cell components |

| Silicon Carbide (SiC) | 10–30μm | SLM | High thermal conductivity, wear-resistant | Aerospace heat exchangers, cutting tools |

Focus: Ceramic 3D printing powder types, alumina powder for high-temperature parts, zirconia dental 3D powder.

2. Key Properties of 3D Printing Powder: How They Impact Print Quality

The performance of 3D printed parts depends heavily on powder properties—even small deviations can cause defects like porosity, warping, or poor layer adhesion. Below are the 4 most critical properties:

2.1 Particle Size & Distribution

- Why it matters: Powder particles must be small enough to form thin, uniform layers (20–100μm for most technologies) but not so small that they clump (which disrupts powder bed spreading).

- Ideal range:

- SLM/EBM (metal): 15–53μm (narrow distribution to avoid segregation);

- SLS (plastic): 30–60μm (wider distribution for better sintering);

- Defect risk: Particles >100μm cause uneven layers; particles <10μm lead to agglomeration (clumps) and poor flow.

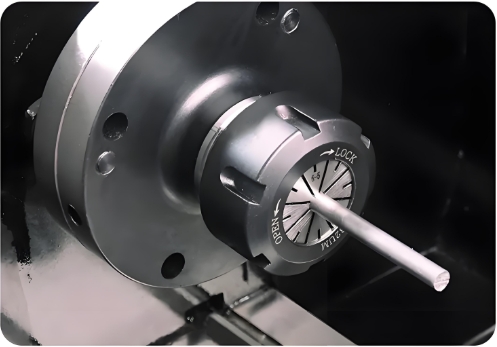

2.2 Flowability

- Why it matters: Good flowability ensures the powder spreads evenly across the build platform (critical for consistent layer thickness). Flowability is measured by the “angle of repose” (lower angle = better flow).

- Ideal angle of repose:

- Metal powders: <35° (e.g., Ti-6Al-4V powder typically has a 30–32° angle);

- Plastic powders: <40° (PA12 powder often has a 35–38° angle);

- Improvement methods: Add flow agents (e.g., fumed silica) or use spherical powder (more aerodynamic than irregular shapes).

2.3 Purity

- Why it matters: Impurities (e.g., oxygen, carbon, or foreign metals) weaken parts, cause porosity, or damage 3D printing equipment (e.g., laser lenses).

- Industry standards:

- Metal powders: Oxygen content <0.15% (Ti-6Al-4V) or <0.08% (stainless steel 316L);

- Ceramic powders: Purity >99% (alumina for industrial use);

- Testing methods: Use X-ray fluorescence (XRF) or gas chromatography to detect impurities.

2.4 Morphology (Shape)

- Why it matters: Powder shape affects flowability and packing density (how tightly particles fit together).

- Common shapes:

- Spherical: Best for flowability and packing density (used in SLM/EBM);

- Irregular: Lower cost but poorer flow (used in low-cost SLS or binder jetting);

- Packing density impact: Spherical powder has a packing density of 60–70% (vs. 45–55% for irregular powder), leading to denser printed parts.

3. How to Choose 3D Printing Powder: A Step-by-Step Guide

Selecting the right powder requires aligning its properties with your 3D printing technology, part requirements, and budget. Follow these 4 steps:

Step 1: Match Powder to 3D Printing Technology

- SLM/EBM: Choose spherical, high-purity metal powders (15–53μm) or fine ceramic powders (15–40μm);

- SLS/MJF: Opt for plastic powders (30–60μm) with low moisture absorption (e.g., PA12);

- Binder Jetting: Use coarser powders (20–80μm) (e.g., stainless steel or alumina) to avoid clogging nozzles.

Step 2: Define Part Requirements

- Strength: For structural parts (e.g., aerospace components), choose Ti-6Al-4V or Inconel 718 metal powder;

- Flexibility: For rubber-like parts, select TPE or PA11 plastic powder;

- Heat resistance: For high-temperature applications, use alumina or SiC ceramic powder.

Step 3: Consider Cost & Availability

- Low budget: Irregular stainless steel (316L) or PA12 plastic powder;

- High performance: Spherical Ti-6Al-4V or Zirconia powder (higher cost but better quality);

- Availability: Common powders (PA12, 316L) are in stock; specialty powders (Inconel 718, SiC) may require 2–4 weeks lead time.

Step 4: Verify Quality Certifications

- Look for powders certified to industry standards:

- Metal powders: ASTM F2924 (standard for metal powder for AM);

- Plastic powders: ISO 11130 (plastic powder quality);

- Ask suppliers for a “Certificate of Analysis (CoA)” to confirm purity, particle size, and morphology.

Focus: 3D printing powder Selection Guide,how to choose metal powder for SLM, SLS plastic powder selection.

4. Common Myths About 3D Printing Powder (And the Facts)

Myth 1: “The finer the powder, the better the print quality.”

Fact: Too-fine powder (<10μm) clumps easily, leading to uneven powder beds and defects. Most technologies require a balanced range (15–60μm) to ensure flowability and layer uniformity.

Myth 2: “Used 3D printing powder can’t be reused.”

Fact: Used powder (recycled powder) can be reused 3–5 times after screening (to remove large particles) and drying (to reduce moisture). Recycled powder may have slightly lower flowability, so mix it with 50% fresh powder for best results.

Myth 3: “All metal powders for SLM are interchangeable.”

Fact: Each metal powder has unique melting points and laser absorption rates. For example, aluminum powder (melting point 660°C) requires a lower laser power than titanium powder (melting point 1668°C)—using the wrong powder can damage the printer or produce weak parts.

Myth 4: “Plastic 3D printing powder is only for prototypes.”

Fact: High-performance plastic powders (e.g., PA12 with glass fiber) have tensile strength comparable to injection-molded plastics and are used for end-use parts (e.g., automotive interior components, medical device housings).

Focus: 3D printing powder common myths, recycled metal powder reuse, SLM powder interchangeability.

5. Frequently Asked Questions (FAQs) About 3D Printing Powder

Q1: How should I store 3D printing powder to maintain quality?

A1: Store powder in airtight containers at 20–25°C with <50% humidity. Metal powders need oxygen-free storage (use vacuum-sealed bags) to prevent oxidation; plastic powders need moisture-proof storage (use desiccants) to avoid clumping.

Q2: Can I mix different types of 3D printing powder?

A2: Not recommended. Mixing powders (e.g., PA12 and TPE) can cause inconsistent sintering and weak parts. The only exception is mixing recycled and fresh powder of the same material (e.g., 50% recycled PA12 + 50% fresh PA12).

Q3: What is the cost of 3D printing powder?

A3: Costs vary by material:

- Plastic powder: $50–$200/kg (PA12: ~$80/kg);

- Metal powder: $200–$5,000/kg (316L: ~$300/kg; Ti-6Al-4V: ~$1,500/kg);

- Ceramic powder: $300–$2,000/kg (alumina: ~$500/kg; zirconia: ~$1,200/kg).

Q4: How do I dispose of unused 3D printing powder?

A4: Follow local regulations:

- Plastic powder: Can be incinerated (if biodegradable like PA11) or sent to plastic recycling facilities;

- Metal powder: Recycled by metal refineries (avoid landfill, as some metals are toxic);

- Ceramic powder: Disposed of as non-hazardous waste (check local guidelines).

Conclusion: 3D Printing Powder Is the “Foundation” of High-Quality AM Parts

The right 3D printing powder can make or break your additive manufacturing project—whether you’re printing a medical implant, automotive part, or consumer prototype. By focusing on key properties (particle size, flowability, purity) and matching powder to your technology, you’ll consistently produce strong, defect-free parts.

If you have specific needs (e.g., “looking for powder for SLM dental implants” or “low-cost SLS plastic powder”), share your requirements in the comments—we’ll help you find the perfect match!