Lately, I’ve seen a lot of questions on manufacturing forums like “What even is 5-axis CNC milling?” and “If 3-axis can handle machining, why spend big money on 5-axis?” — As a mechanical engineer with 5 years in the field, I’ll break this down with real cases and technical details, explaining everything from definitions and principles to practical applications. My goal is to help you grasp the core value of 5-axis CNC milling in plain language.

I. First, the Basics: What Makes 5-Axis CNC Milling Unique?

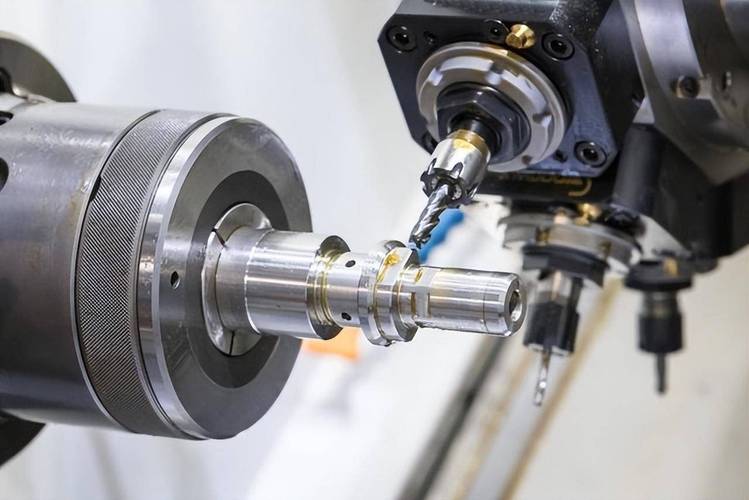

Let’s start with a key point: 5-axis CNC milling isn’t just “3 axes plus 2 extra moving ones” — it’s a precision machining technology that lets the cutting tool/workpiece move simultaneously across 5 dimensions. These 5 axes fall into two categories, each with a distinct movement logic:

-

Linear Axes (X/Y/Z): These are the “basics” shared by both 3-axis and 5-axis machines, and you can think of them as the “translation directions of the cutting tool”:

- X-axis: Left-right movement (e.g., the tool sliding along the length of the workpiece);

- Y-axis: Forward-backward movement (along the width of the workpiece);

- Z-axis: Up-down movement (controlling cutting depth along the height of the workpiece).

Simply put, 3-axis machines only let the tool “cut horizontally or vertically” — like chopping potatoes on a board, you can only slice from three directions: up/down, left/right, forward/backward.

-

Rotary Axes (usually A/B axes; some models use A/C axes): This is the “core upgrade” of 5-axis machines, responsible for “adjusting the angle of the workpiece or tool”:

- A-axis: Rotation around the X-axis (e.g., “flipping” the workpiece so the tool can reach its sides);

- B-axis: Rotation around the Y-axis (e.g., “spinning” the workpiece to cut inclined or curved surfaces).

With these two axes, it’s like adding a “wrist” to the tool — it can not only translate but also “tilt or flip,” allowing it to access the workpiece from nearly any angle.

Here’s a concrete example: If you need to machine a “cube with angled holes,” a 3-axis machine would require you to cut one side first, then disassemble the workpiece, reposition it, and re-clamp it (calibration alone can take 30 minutes). Worse, re-clamping often introduces errors that skew the hole positions. A 5-axis machine, though, can adjust the workpiece angle directly via the A/B axes — one setup, all surfaces machined, and tolerances kept under 0.02mm.

II. Two Core Operating Modes of 5-Axis CNC Milling: Not All “5-Axis” Are the Same

Many people mistakenly think 5-axis means “all 5 axes spinning at once.” In reality, it has two main modes tailored to different machining needs:

1. Indexed Machining (3+2 Axis Machining): “Position First, Cut Later” — The Cost-Effective Choice

This mode follows the logic: “Lock the angle first, then cut with 3 axes.” Put simply, the A/B axes adjust the workpiece to a required angle (e.g., 45°), then the rotary axes lock in place, and the X/Y/Z axes cut as they would on a 3-axis machine.

Suitable Scenarios: “Multi-sided parts” that don’t require continuous curved surfaces (e.g., brackets with multiple angled holes, stepped irregular parts).

Advantages: Lower programming difficulty (similar to 3-axis), relatively low equipment costs (some 3-axis machines can be upgraded to 3+2 axis), and high machining stability.

Disadvantages: Cannot machine continuous complex curved surfaces (e.g., the curved shape of turbine blades).

Suitable Scenarios: “Multi-sided parts” that don’t require continuous curved surfaces (e.g., brackets with multiple angled holes, stepped irregular parts).

Advantages: Lower programming difficulty (similar to 3-axis), relatively low equipment costs (some 3-axis machines can be upgraded to 3+2 axis), and high machining stability.

Disadvantages: Cannot machine continuous complex curved surfaces (e.g., the curved shape of turbine blades).

2. Simultaneous Machining (Full 5-Axis Machining): “All 5 Axes Moving Together” — A Must for Complex Parts

In this mode, the X/Y/Z/A/B axes move simultaneously. For example, when machining a turbine blade, the tool cuts downward along the Z-axis while the A-axis rotates the workpiece and the B-axis fine-tunes the angle — ensuring the tool always contacts the curved surface at the “optimal cutting angle” (avoiding “tool rubbing” or “incomplete cuts”).

Suitable Scenarios: High-precision parts with continuous curved surfaces (e.g., aerospace engine turbine blades, artificial joints, mold cavities).

Advantages: Can machine parts that 3-axis machines “can’t touch at all”; achieves better surface roughness (e.g., Ra 0.8μm, compared to 3-axis which often requires post-polishing); and extends tool life (optimal angles reduce wear).

Disadvantages: Complex programming (requires professional CAD/CAM software like Mastercam or UG, plus collision detection); high equipment costs (entry-level models start at 500,000 RMB); and high operator requirements (1–2 years of experience + specialized training).

Suitable Scenarios: High-precision parts with continuous curved surfaces (e.g., aerospace engine turbine blades, artificial joints, mold cavities).

Advantages: Can machine parts that 3-axis machines “can’t touch at all”; achieves better surface roughness (e.g., Ra 0.8μm, compared to 3-axis which often requires post-polishing); and extends tool life (optimal angles reduce wear).

Disadvantages: Complex programming (requires professional CAD/CAM software like Mastercam or UG, plus collision detection); high equipment costs (entry-level models start at 500,000 RMB); and high operator requirements (1–2 years of experience + specialized training).

III. 5-Axis vs. 3-Axis: What “Irreplaceable Advantages” Does 5-Axis Offer?

Many people wonder “whether to invest in 5-axis.” The key is understanding which “pain points” 5-axis solves that 3-axis can’t. From my hands-on experience, here are 4 core advantages:

1. Machining “Impossible” Complex Parts: Breaking 3-Axis Limits

The biggest limitation of 3-axis machines is their “fixed tool angle.” For example, machining a “part with concave curved surfaces” (like a car gearbox housing) — a 3-axis tool can only cut from the front, never reaching the concave areas. A 5-axis machine, though, adjusts the workpiece angle via rotary axes, letting the tool “reach inside” to cut. It can even machine “spatial curved parts” like turbine blades: 3-axis machining leaves obvious “seam marks” that require manual polishing, while 5-axis achieves a smooth surface in one pass.

2. Fewer Setups: Reducing Errors and Boosting Efficiency

3-axis machining for multi-sided parts requires repeated disassembly and re-clamping (e.g., a hexahedron needs at least 3 setups). Each setup introduces errors (e.g., 0.03mm calibration deviation per setup = 0.09mm total) and wastes time (20–30 minutes per setup + calibration).

5-axis machines, by contrast, “finish all surfaces in one setup.” I once worked on an aerospace part (a rectangular block with angled holes): 3-axis machining took 4 setups, 2 hours total, and a 0.1mm tolerance. With 5-axis, it took 1 setup, 40 minutes, and the tolerance dropped to 0.02mm — fully meeting aerospace precision standards.

5-axis machines, by contrast, “finish all surfaces in one setup.” I once worked on an aerospace part (a rectangular block with angled holes): 3-axis machining took 4 setups, 2 hours total, and a 0.1mm tolerance. With 5-axis, it took 1 setup, 40 minutes, and the tolerance dropped to 0.02mm — fully meeting aerospace precision standards.

3. Shorter Processing Cycles: Cutting “Waiting and Rework”

Beyond setup time, 5-axis also reduces “tool changes” and “post-processing steps”:

- For example, machining a part with “threads + angled holes + curved surfaces”: 3-axis needs 3 tool changes (end mill, drill, tap) and 3 separate processes; 5-axis uses a single composite tool, adjusting angles to finish all work in one go.

- 3-axis machining of curved surfaces typically achieves a surface roughness of Ra 3.2μm, requiring 1 hour of post-polishing per part. 5-axis, though, can directly reach Ra 0.8μm, eliminating polishing entirely. When I worked on medical “artificial joints,” 5-axis cut polishing time from 1.5 hours to zero — letting us produce 20 more parts per day in mass production.

4. Longer Tool Life: Lower Long-Term Costs

A detail many overlook: cutting angle has a huge impact on tool wear. When 3-axis machines cut inclined surfaces (e.g., using a 90° end mill on a 45° slope), only the “tip of the tool” makes contact — leading to quick wear (one tool might only last 50 parts). 5-axis machines, though, adjust the angle to let the “entire cutting edge” contact the workpiece, distributing force evenly. This extends tool life by 30–50% (e.g., the same tool can machine 70–80 parts with 5-axis).

IV. 3-Axis vs. 5-Axis: A Table to Help You “Choose the Right One”

Many ask “do I really need 5-axis?” The answer boils down to “matching your needs.” Below is a comparison table to help you decide quickly:

| Comparison Dimension | 3-Axis CNC Milling | 5-Axis CNC Milling |

|---|---|---|

| Number of Axes | X/Y/Z (3 linear axes) | X/Y/Z (linear) + A/B (rotary axes) |

| Processing Complexity | Only flat surfaces, straight holes, simple steps | Complex curved surfaces, multi-sided irregular parts |

| Number of Setups | Multiple (usually 2–5) | 1 (most scenarios) |

| Machining Precision | Moderate (tolerance: 0.05–0.1mm) | High precision (tolerance: 0.01–0.03mm) |

| Equipment Cost | 100,000–500,000 RMB (entry-level) | 500,000–3,000,000 RMB (entry to high-end) |

| Programming Difficulty | Moderate (basic G-code suffices) | High (requires CAD/CAM + collision detection) |

| Operator Requirements | 1–3 months of training to master | 1–2 years of experience + specialized training |

| Suitable Scenarios | Simple parts (e.g., flanges, brackets) | Complex high-precision parts (aerospace, medical, molds) |

In short: If your needs are “simple parts, large batches, limited budget,” 3-axis is enough. If you need “complex parts, high precision, and less rework,” 5-axis is a must.

V. The “Pitfalls” of 5-Axis CNC Milling: Things to Consider in Advance

While 5-axis has clear advantages, it’s not “plug-and-play.” I’ve seen many companies invest blindly in 5-axis, only to let the equipment sit idle due to these issues:

1. High Costs: It’s Not Just “Buying the Machine” — There Are Follow-Up Expenses

The “hidden costs” of 5-axis are higher than you might think:

- Programming software: Annual service fees for genuine CAD/CAM software (e.g., UG NX) can cost 50,000–100,000 RMB;

- Tools: 5-axis-specific tools like “extended toolholders” and “ball end mills” cost 2–3x more than 3-axis tools;

- Maintenance: Rotary axis bearings need regular replacement, with a single maintenance service costing 10,000–20,000 RMB;

- Labor: 5-axis programmers earn 50–80% more than 3-axis programmers (e.g., a 3-axis programmer makes 8,000 RMB/month, while a 5-axis one might make 12,000–15,000 RMB/month).

2. Difficult Programming: “Mastering 3-Axis Doesn’t Equal Mastering 5-Axis”

The core challenge of 5-axis programming is “collision detection.” For example, when the A-axis rotates, the toolholder might hit the workpiece or machine fixture. A collision can break the tool (hundreds of RMB in losses) or even ruin the machine spindle (hundreds of thousands of RMB in losses).

Early in my 5-axis career, I failed to do collision detection properly — the toolholder hit the workpiece, and the repair cost alone was 20,000 RMB. That’s why you must use specialized software (e.g., Vericut) for “virtual simulation” — confirm no collisions before running the machine. This step is non-negotiable.

Early in my 5-axis career, I failed to do collision detection properly — the toolholder hit the workpiece, and the repair cost alone was 20,000 RMB. That’s why you must use specialized software (e.g., Vericut) for “virtual simulation” — confirm no collisions before running the machine. This step is non-negotiable.

3. Small Batches: It Might “Not Be Worth It”

If your parts are in small batches (e.g., 1–2 pieces at a time), 5-axis “setup time” (programming + calibration) might be longer than the machining time itself. For example, a 3-axis machine can machine a bracket in 1 hour, while a 5-axis might take 2 hours (1.5 of which is programming and calibration) — making 3-axis more efficient in this case.

VI. Conclusion: The Core Value of 5-Axis CNC Milling Is “Solving What 3-Axis Can’t”

To wrap up: 5-axis CNC milling isn’t just an “upgrade of 3-axis” — it’s a “new tool for complex, precision manufacturing”. Its value isn’t about “being faster than 3-axis,” but about “doing what 3-axis can’t, and doing it better when 3-axis falls short.”

If you work in aerospace, medical devices, or high-end mold making, 5-axis is a “necessary investment.” But if you only make simple mechanical parts, blind investment in 5-axis will only increase costs.

If you have specific questions — like “Can a certain part be machined with 5-axis?” or “How to choose an entry-level 5-axis machine?” — or want tips on using programming software, feel free to leave a comment below. I’ll help you answer them with real-world cases!