1. What is CNC Machining?

1.1 Basic Concept of CNC Machining

- Computer Control: Using program code instead of manual operation

- Automatic Operation: Machines automatically complete processing according to programs

- Ultra-Precision: Errors can be controlled within a fraction of a human hair

- Consistency: All mass-produced parts are identical

1.2 Differences Between CNC Machining and Traditional Machining

|

Aspect

|

CNC Machining

|

Traditional Machining

|

|

Operator

|

Computer program control

|

Manual operation by skilled workers

|

|

Precision Level

|

Ultra-precise (0.001mm)

|

Relatively precise (0.01mm)

|

|

Part Consistency

|

All parts are identical

|

Each part may have slight differences

|

|

Capabilities

|

Can easily handle complex shapes

|

Mainly for simple shapes

|

|

Product Changeover

|

Just modify the program

|

Need to readjust the machine

|

|

Skill Requirements

|

Programming and computer operation

|

Manual craftsmanship and experience

|

1.3 Development History of CNC Machining

- 1952: The first CNC machine tool was born in the United States, controlled by vacuum tubes

- 1959: Transistors were adopted, making it smaller and more reliable

- 1965: Integrated circuits began to be used

- 1970: Minicomputers began to be applied

- 1974-present: Microprocessor era, which is the CNC system we use now

2. How Does CNC Machining Work?

2.1 Basic Working Principle

- Engineers draw 3D models of parts using computer software (such as SolidWorks)

- This model contains all information about the part’s shape, size, material, etc.

- Import the designed 3D model into another software (CAM software)

- The software calculates the tool path based on the part shape

- Finally, generate code that the machine can understand (G-code)

- Input the program into the CNC machine

- The machine automatically controls the tool movement according to program instructions

- Gradually transforms the raw material into the desired part shape

- Like drawing the “construction blueprint” for the part

- Using specialized design software, precise to every detail

- Save in a file format recognizable by computers

- Telling the machine “how to make” this part

- Selecting appropriate tools and processing methods

- Calculating tool movement routes and speeds

- Generating executable code for the machine

- Fixing raw materials on the machine workbench

- Installing the required tools

- Telling the machine where the part is located

- Transferring the programmed code to the machine

- First run a trial to ensure no problems

- Start formal processing

- The machine automatically works according to the program

- The operator only needs to monitor the process

- After processing is completed, check the part dimensions

- Ensure compliance with design requirements

- Remove burrs and perform surface treatment

- Qualified parts are ready for use

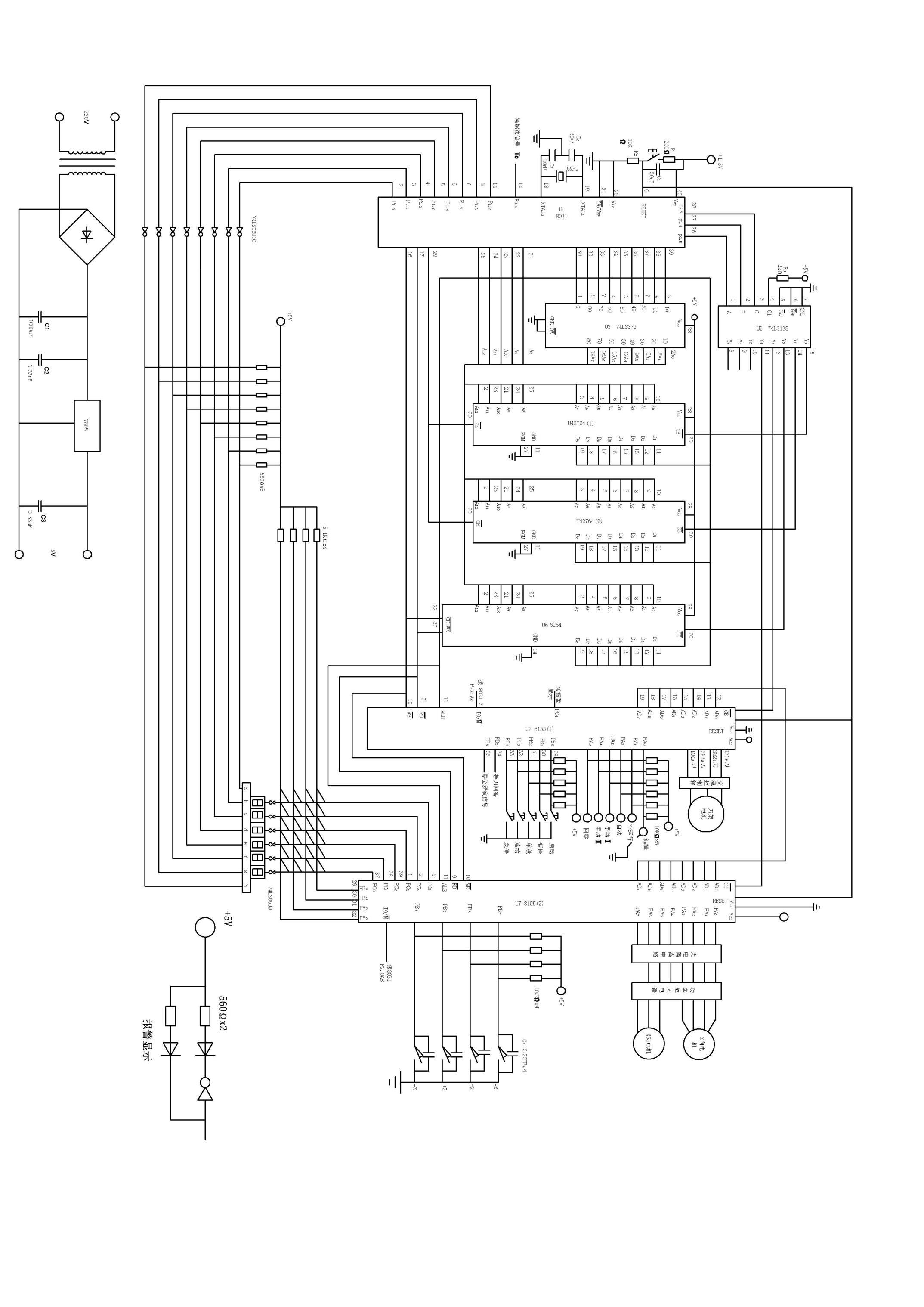

2.3 The “Language” Machines Understand – G-code

|

G-code

|

Function Description

|

Simple Understanding

|

|

G00

|

Rapid Positioning

|

Tool moves quickly to specified position

|

|

G01

|

Linear Interpolation

|

Tool moves along a straight line

|

|

G02/G03

|

Circular Interpolation

|

Tool moves along an arc

|

|

G04

|

Dwell

|

Tool pauses for a period of time

|

|

G28

|

Return to Origin

|

Tool returns to initial position

|

3. What Components Make Up a CNC Machine?

3.1 “Body Structure” of CNC Machines

- Bed and Column: Like the human skeleton, supporting the entire machine

- Spindle: The part that drives the tool or workpiece to rotate

- Worktable: The place where raw materials are placed, which can move

- Guideways: Ensuring precision and stability of movement

- Control Panel: The human-machine interface where operators work

- Display Screen: Showing programs and processing status

- Processor: Like a computer’s CPU, processing various instructions

- Servo Motors: Providing power to make the machine move

- Ball Screws: Converting rotational motion into linear motion

- Reducers: Controlling motion speed and torque

3.2 “Nervous System” of CNC Machines

- Encoders: Detecting motor speed and position

- Linear Scales: Detecting the precise position of the worktable

- Sensors: Monitoring various parameters during processing

- The computer issues an instruction to “move to position 100mm”

- The motor drives the worktable to start moving

- Sensors real-time detect the actual position

- If it finds that only 99.99mm has been moved, it will continue adjusting

- It stops only when it accurately reaches the 100mm position

4. What Types of CNC Machining Are There?

4.1 Classification by Processing Method

- Working Method: Workpiece rotates, tool moves

- Processed Parts: Shafts, discs (such as transmission shafts, flanges)

- Characteristics: Specialized in processing round parts

- Working Method: Tool rotates, workpiece moves

- Processed Parts: Complex-shaped parts (such as boxes, brackets)

- Characteristics: Can process planes, grooves, complex curved surfaces

- CNC Drilling Machines: Specialized machines for drilling holes

- Machining Centers: Comprehensive processing equipment with more complete functions

- EDM (Electrical Discharge Machining): Special method for processing hard materials

4.2 Classification by Number of Axes

- Axis Configuration: X, Y, Z directions (front-back, left-right, up-down)

- Capability: Can process most common parts

- Application: General mechanical manufacturing

- Axis Configuration: Three linear axes + one rotational axis

- Capability: Can process more complex 3D shapes

- Application: Mold manufacturing, aviation parts

- Axis Configuration: Three linear axes + two rotational axes

- Capability: Can process all surfaces of a part in one clamping

- Application: Aerospace, precision molds

5. What Are the Advantages and Disadvantages of CNC Machining?

5.1 “Superpowers” of CNC Machining

- Processing errors can be controlled within 0.001mm

- Much finer than a human hair

- All mass-produced parts are identical

- Can work 24 hours a day without interruption

- Multiple processing steps can be completed in one clamping

- Changing products only requires program modification, very flexible

- Can process complex parts that traditional machine tools cannot

- Can process various materials (metals, plastics, composite materials)

- Can handle both large and small parts

- Controlled by software, relatively simple to operate

- Can be remotely monitored and managed

- Processing process data can be completely recorded

5.2 “Minor Disadvantages” of CNC Machining

- High equipment investment cost

- Maintenance costs are also not low

- Software purchase is also needed

- Requires professional operators

- Programming also requires specialized knowledge

- Maintenance also requires technical personnel

- Belongs to “subtractive manufacturing”, generates a lot of chips

- For precious materials, the waste cost is high

5.3 Where is CNC Machining Used?

- Processed Parts: Aircraft engine blades, fuselage structural parts

- Requirements: High precision, high strength, complex shapes

- Characteristics: Small batch, high value

- Processed Parts: Engine blocks, transmission parts

- Requirements: Large batch, high efficiency, good consistency

- Characteristics: High degree of production line automation

- Processed Parts: Artificial joints, surgical instruments

- Requirements: Ultra-high precision, smooth surface, good biocompatibility

- Characteristics: Small batch customization

- Processed Parts: Mobile phone cases, connectors, heat sinks

- Requirements: High precision, good appearance, fast updates

- Characteristics: Mass production

6. How to Choose the Right Processing Method?

6.1 Basic Selection Principles

- Small batch (below 1000 pieces): Suitable for CNC machining

- Medium batch (1000-10000 pieces): Need to comprehensively consider costs

- Large batch (above 10000 pieces): Other methods like stamping may be more cost-effective

- Simple parts: Traditional processing may be more economical

- Complex parts: Must use CNC machining

- Precision parts: CNC machining is the first choice

- General precision: Traditional processing can meet requirements

- High precision: Must use CNC machining

6.2 Recommendations for Enterprises

- Choose suitable equipment according to your own processing needs

- Consider future development and reserve expansion space

- Choose brands with reliable quality and good service

- Strengthen skill training for operators

- Cultivate technical personnel who understand programming

- Establish a professional technical team

- Strictly implement the first article inspection system

- Real-time monitoring of processing processes

- Regular maintenance and calibration of equipment

7. Future Development of CNC Machining

7.1 Technology Development Trends

- Artificial Intelligence Application: Machines can optimize processing parameters by themselves

- Digital Twin: Establishing virtual machine models to simulate processing in advance

- Autonomous Decision Making: Machines can make decisions by themselves based on conditions

- Developing towards nanoscale precision

- Processing surfaces becoming smoother and smoother

- More advanced online measurement and compensation technology

- More energy-efficient equipment

- Reducing the use of cutting fluids

- Chip recycling and reuse

7.2 Application Field Expansion

- New Energy Vehicles: Battery casings, motor parts

- 3D Printing Combination: Hybrid manufacturing of CNC machining and 3D printing

- Personalized Customization: Production of small-batch personalized products

- Remote Services: Manufacturers remotely monitor and maintain equipment

- Cloud Manufacturing: Internet-based manufacturing service platforms

- Smart Manufacturing: Factory automation and intelligence