CNC motorcycle parts are precision components manufactured using Computer Numerical Control (CNC) machining, tailored for motorcycles to enhance performance, durability, and fit. These parts, ranging from engine components to custom bodywork, are produced with high accuracy (±0.01mm) via automated tools, ensuring consistent quality. CNC machining enables complex geometries and tight tolerances, making them ideal for both OEM production and aftermarket upgrades in street, racing, and custom motorcycles.

Detailed Analysis of CNC Motorcycle Parts

1. Core Definition & Manufacturing Precision

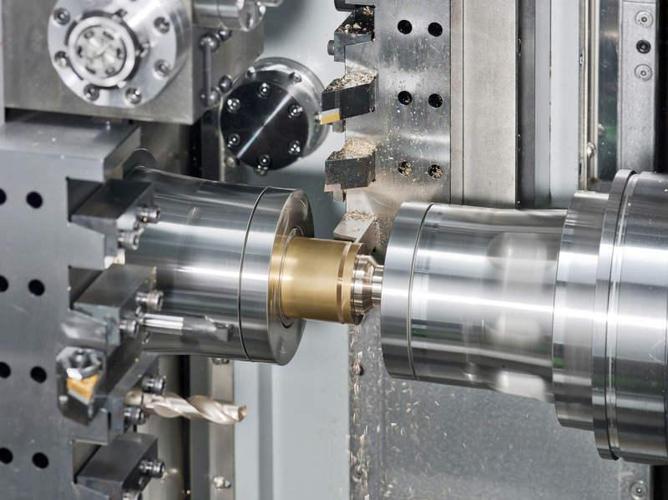

CNC motorcycle parts refer to components crafted using CNC mills, lathes, or routers, where computer programs control tool movements to shape raw materials into precise, functional parts. Unlike traditional casting or forging, CNC machining removes material incrementally, allowing for intricate designs and tight tolerances critical for motorcycle performance. This precision ensures parts fit seamlessly—whether a engine valve cover or a custom handlebar—reducing friction, improving alignment, and enhancing overall reliability.

2. Common Types of CNC Motorcycle Parts

CNC machining produces a wide range of motorcycle components, each serving specific functional or aesthetic roles:

-

Engine Components:

- Cylinder Heads & Blocks: CNC-machined to precise port shapes and valve seat angles, optimizing airflow for increased horsepower. For example, racing bikes use CNC-ported cylinder heads to maximize fuel-air mixture efficiency.

- Crankshafts & Connecting Rods: Balanced and shaped with CNC lathes to reduce vibration, critical for high-rev engines in sport bikes.

- Carburetor/Injection Parts: Throttle bodies and fuel injectors with CNC-drilled passages ensure precise fuel delivery, enhancing throttle response.

-

Transmission & Drivetrain:

- Sprockets & Chain Guides: CNC-cut from hardened steel or aluminum to ensure uniform tooth spacing, reducing chain wear and improving power transfer.

- Gear Components: Shafts and gears with tight meshing tolerances (±0.005mm) minimize backlash, a key factor in smooth shifting for street motorcycles.

-

Suspension & Chassis:

- Fork Sliders & Shock Mounts: Machined from high-strength aluminum (7075) to reduce weight while maintaining structural integrity, critical for handling in off-road bikes.

- Frame Brackets & Linkages: Custom CNC brackets for aftermarket suspension upgrades, ensuring precise alignment between components.

-

Custom & Aesthetic Parts:

- Handlebars & Controls: Ergonomically shaped aluminum handlebars with CNC-machined grips and lever pivots, tailored for comfort and style in custom cruisers.

- Body Panels & Trim: Lightweight carbon fiber or aluminum fairings with CNC-cut mounting points, common in racing bikes for aerodynamic efficiency.

3. Materials Used in CNC Motorcycle Parts

Material selection balances strength, weight, and cost, with CNC machining adapting to diverse substrates:

-

Aluminum Alloys:

- 6061 Aluminum: Widely used for non-load-bearing parts (covers, brackets) due to its machinability and moderate strength. It’s lightweight (2.7 g/cm³) and cost-effective for OEM parts.

- 7075 Aluminum: Preferred for high-stress components (suspension links, swingarms) thanks to its high tensile strength (570 MPa) and fatigue resistance, ideal for racing applications.

-

Steels:

- 4130 Chromoly Steel: Used for frame components and drivetrain parts (sprockets) due to its strength-to-weight ratio and weldability, common in off-road and vintage motorcycle builds.

- Stainless Steel (304/316): Resists corrosion, making it suitable for exhaust flanges, fasteners, and marine/mud motorcycle parts exposed to harsh environments.

-

Titanium Alloys (Ti-6Al-4V):

A premium choice for high-performance parts (valves, exhaust headers) due to its exceptional strength-to-weight ratio and heat resistance. Though expensive, it reduces overall motorcycle weight, improving acceleration and handling in racing. -

Carbon Fiber Composites:

CNC-machined carbon fiber parts (fairings, fenders) offer ultra-lightweight properties with high rigidity, favored in MotoGP and superbike racing for aerodynamic advantages.

4. Manufacturing Process for CNC Motorcycle Parts

The production workflow ensures precision and consistency:

-

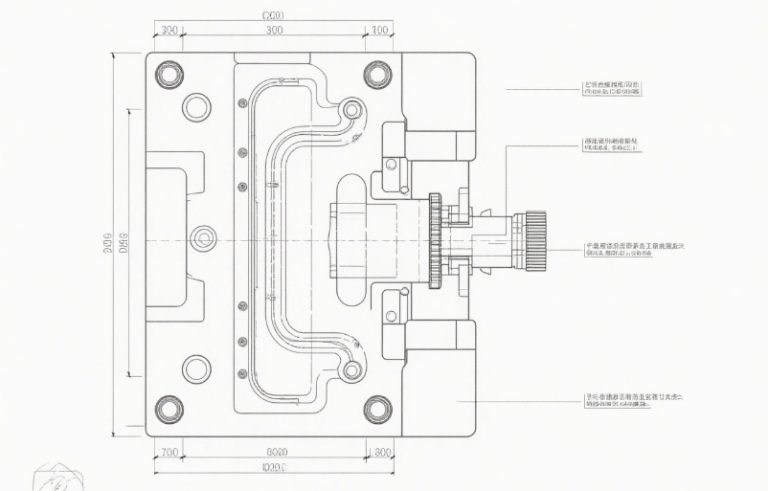

Design & Programming:

Engineers use CAD software (SolidWorks, Fusion 360) to model parts, incorporating performance requirements (e.g., heat dissipation for engine parts). CAM software converts designs into toolpaths, optimizing feeds (500–2000 mm/min) and speeds (10,000–20,000 RPM) for the chosen material. -

Material Preparation:

Raw stock (aluminum billets, steel bars) is cut to near-net shape to minimize machining time. For high-strength parts, pre-heat treatment (annealing) softens the material for easier cutting. -

CNC Machining:

- Roughing: Removes bulk material with large end mills, prioritizing speed to reduce cycle time.

- Finishing: Uses smaller tools (3–6mm carbide end mills) for tight tolerances and smooth surfaces (Ra <1.6μm), critical for sealing surfaces like cylinder heads.

- Multi-Axis Machining: 4/5-axis CNC machines create complex 3D shapes (e.g., curved fork legs) in a single setup, reducing errors from multiple operations.

-

Post-Processing:

- Heat Treatment: Parts like steel sprockets undergo quenching/tempering to harden surfaces (50–60 HRC) for wear resistance.

- Surface Finishing: Anodizing (aluminum parts) adds corrosion resistance and color; powder coating (steel parts) enhances durability. Polishing creates smooth surfaces for reduced friction in moving components.

-

Inspection:

CMMs (Coordinate Measuring Machines) verify dimensions, while optical comparators check surface finish. For critical parts (engine valves), X-ray or ultrasonic testing detects internal defects.

5. Applications in Motorcycle Sectors

CNC motorcycle parts serve diverse segments, driven by performance and customization needs:

-

OEM Production: Major manufacturers (Honda, Yamaha) use CNC machining for critical parts like engine blocks and transmission gears, ensuring consistency across thousands of units. Tight tolerances reduce warranty issues and improve reliability.

-

Aftermarket & Performance Upgrades: Companies like Akrapovič or Yoshimura offer CNC-machined exhaust headers and intake systems, optimizing airflow to boost horsepower by 10–20% in street bikes.

-

Racing & Motorsports: MotoGP and Superbike teams rely on custom CNC parts—lightweight titanium valves, carbon fiber fairings—to shave milliseconds off lap times. Every gram saved improves acceleration and handling.

-

Custom & Vintage Builds: Enthusiasts use CNC machining to recreate rare parts for vintage motorcycles (e.g., 1970s Ducati components) or craft one-of-a-kind designs, blending classic aesthetics with modern performance.

6. Advantages Over Traditional Manufacturing

CNC motorcycle parts outperform traditionally made components in key areas:

- Precision Fit: Tight tolerances (±0.01mm) eliminate gaps between mating parts, reducing leaks in engines and improving suspension responsiveness.

- Complex Geometries: CNC machining creates shapes impossible with casting, such as optimized port designs in cylinder heads or aerodynamic fairing contours.

- Customization Flexibility: Easy to adapt designs for specific needs—from a rider’s ergonomic handlebar preferences to racing teams’ weight reduction goals.

- Durability: Machined parts have uniform material density (no porosity from casting), enhancing fatigue resistance in high-stress components like connecting rods.

CNC motorcycle parts combine precision engineering with material science to elevate motorcycle performance, reliability, and customization. From OEM production to high-end racing, their role in shaping modern motorcycles—balancing power, weight, and durability—makes them indispensable in the industry.