Answer

CNC precision machining refers to a manufacturing process using computer numerical control (CNC) technology to remove material via high-precision machine tools, achieving part dimensional tolerances ≤±0.01mm and surface roughness Ra≤0.8μm. It is widely applied in aerospace, medical devices, precision molds, and other fields.

Extended Response

I. Core Definition and Technical Essence

1. Precision Grading

- General precision: Dimensional tolerance ±0.1mm, surface roughness Ra1.6-3.2μm (suitable for general mechanical parts);

- Precision grade: Tolerance ±0.01-0.05mm, Ra0.4-0.8μm (e.g., automotive engine crankshafts);

- Ultra-precision grade: Tolerance ≤±0.001mm, Ra≤0.025μm (e.g., optical lens molds).

CNC precision machining typically refers to processes meeting or exceeding precision-grade standards.

2. Fundamental Differences from Traditional Machining

- Digital control: CNC systems precisely control toolpaths via G-code, with repeat positioning accuracy up to ±0.005mm (traditional machines ±0.05mm);

- Closed-loop feedback: Equipped with real-time monitoring systems like laser measurement and raster scales to automatically compensate for thermal deformation (e.g., errors from spindle heating);

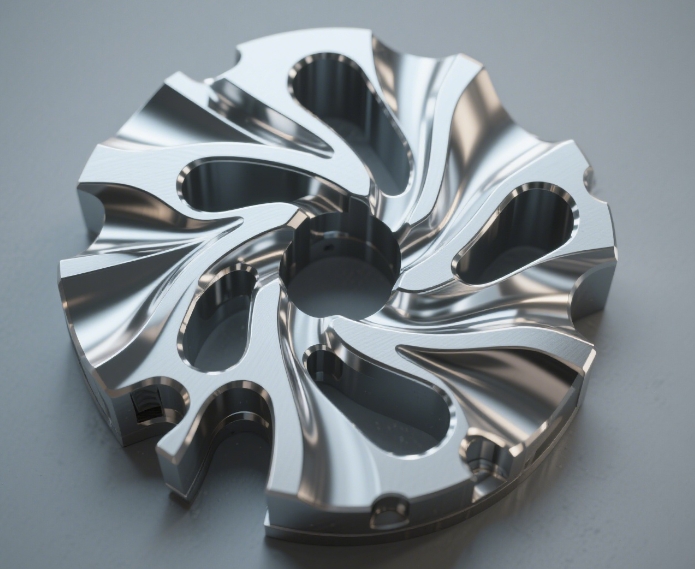

- Multi-axis linkage: 5-axis/6-axis machines control ≥3 axes simultaneously for complex surfaces like turbine blades (traditional machines require multi-process splitting).

II. Key Technical Elements

1. High-Precision Machine Tools

- Spindle system: Electro-spindles (speed ≥20,000rpm) with runout ≤0.001mm (e.g., German GMN spindles);

- Guideways and lead screws: Hydrostatic guideways or linear motor drives, positioning accuracy ±0.003mm (e.g., Japanese THK lead screws);

- Bed structure: Marble/cast iron beds (thermal expansion coefficient ≤10^-6/℃) to suppress vibration (e.g., Swiss Mikron UCP series machines).

2. Precision Tools and Fixtures

- Tool materials: PCD (polycrystalline diamond) for aluminum mirror machining, CBN (cubic boron nitride) for hardened steel (HRC≥55);

- Tool geometry: Micro-milling cutters ≤0.1mm diameter (for smartphone camera brackets), edge sharpness ≤0.5μm;

- Fixture systems: Hydraulic/pneumatic fixtures with repeat positioning accuracy ±0.002mm, e.g., Swedish 3R zero-point positioning systems.

3. Process Optimization Strategies

- Cutting parameters:

- Aluminum alloys: Cutting speed 3,000-5,000m/min, feed 0.01-0.05mm/tooth;

- Titanium alloys: Cutting speed 50-100m/min, depth of cut ≤0.5mm (to avoid chatter);

- Toolpath design: Contour machining replaces reciprocating milling to reduce tool marks (e.g., mold cavity machining);

- Cooling methods: Cryogenic air (-30℃) for titanium alloys suppresses tool wear (tool life increased by 40%).

III. Typical Application Fields

1. Aerospace

- Key components: Turbine blades (nickel-based alloys, profile tolerance ±0.005mm), satellite frames (aluminum alloys, wall thickness 0.5mm);

- Technical challenges: Low material removal rate (titanium alloys only 50-100cm³/min), requiring multi-axis linkage to avoid tool interference.

2. Medical Devices

- Typical products: Joint prostheses (titanium alloys, surface roughness Ra≤0.2μm), insulin pump precision gears (POM material, module 0.3mm);

- Special requirements: Compliance with ISO 13485 medical device certification, metal residue-free processing (e.g., dry cutting).

3. Electronics & 3C

- Representative parts: Smartphone mid-frames (magnesium-aluminum alloys, flatness ≤0.008mm), camera brackets (plastic + stainless steel inserts);

- Trend: Moving toward “micron-level” precision, e.g., 5G base station filter cavities with machining accuracy ±0.002mm.

IV. Quality Control System

1. On-line Inspection Technologies

- Laser scanning: German ZEISS O-INSPECT composite measuring instruments detect dimensions and geometric tolerances simultaneously (e.g., cylindricity ≤0.001mm);

- Contact measurement: Renishaw probes real-time correct tool compensation values for thermal deformation errors (e.g., spindle elongation 0.001mm per 1℃ temperature rise).

2. Error Compensation Strategies

- Thermal error compensation: Establish machine thermal models, adjust coordinates via temperature sensor feedback (e.g., Mazak’s Thermal Shield technology);

- Geometric error compensation: Laser interferometers detect 21 geometric errors, automatically corrected by CNC systems (e.g., Renishaw XL-80).

3. Process Capability Analysis

- CPK value: Critical dimensions CPK≥1.67 (defect rate <0.006%), e.g., automotive engine cylinder bore machining;

- SPC control: Real-time collection of processing data, automatic alarm when dimension fluctuations exceed ±3σ (e.g., medical implant production).

V. Comparison with Other Processes

| Process Type | Dimensional Precision | Surface Roughness | Complex Structure Adaptability | Unit Cost |

|---|---|---|---|---|

| CNC precision machining | ≤±0.001mm | Ra≤0.025μm | Tool accessibility required | Medium-high |

| 3D printing (metal SLM) | ±0.05mm | Ra5-10μm | No restrictions | High |

| Precision casting | ±0.1mm | Ra3.2-6.3μm | Complex internal cavities | Low |

VI. Industry Development Trends

1. Intelligence and Automation

- AI-assisted programming: Siemens Sinumerik ONE system optimizes cutting parameters via deep learning, increasing processing efficiency by 20%;

- Unmanned production lines: Robot loading/unloading + on-line inspection, e.g., GF Machining Solutions’ Mikron HSM 500U LP line enables 24/7 continuous processing.

2. Breakthroughs in Ultra-Precision Machining

- Nanometer-level machining: Toshiba Machine’s NANO-UNITE achieves Ra≤0.005μm mirror finishing (for optical prisms);

- Hybrid machining: Turn-mill composite centers (e.g., DMG MORI CTX beta 1250 TC) complete multi-processes in one setup, geometric tolerance ≤±0.003mm.

3. Green Manufacturing

- Dry cutting: Air 静压 bearings replace lubricating oil to avoid pollution (e.g., Hermle C40U DryCut);

- Cutting fluid recycling: Filtration systems achieve 95% recycling rate (e.g., Blaser Swisslube EcoCool).

VII. Challenges and Solutions

1. Technical Challenges

- Difficult materials: Machining Inconel 718 superalloy generates cutting temperatures >1,000℃, requiring ceramic tools + high-pressure cooling (10MPa);

- Micro-structure machining: Deburring in 0.05mm-wide slots requires ultrasonic vibration cutting (20kHz frequency).

2. Cost Control

- Tool management: Adopt tool life management systems (e.g., Sandvik Coromant’s CoroPlus), reducing tool consumption by 30%;

- Process optimization: Merge multi-parts into integral machining (e.g., aerospace “integral blisks”), reducing assembly errors and processes.

Conclusion

As a core technology in advanced manufacturing, CNC precision machining is evolving toward “sub-micron precision,” “intelligent production,” and “green manufacturing.” From aero-engines to wearable medical devices, precision machining supports innovation in high-end manufacturing, with its development level becoming a key indicator of national manufacturing capabilities.