Coining is a precision metal stamping process that uses high pressure to reshape or imprint metal surfaces, creating detailed, crisp features with tight tolerances. Unlike bending or drawing, it compresses material between a hardened punch and die, forming intricate patterns, text, or contours without removing material. Ideal for creating coins, medals, or precision components, it ensures exceptional surface finish and dimensional accuracy.

Detailed Analysis of Coining in Metal Stamping

1. Technical Principles & Core Characteristics

Coining stands apart from other stamping processes due to its focus on compression and precision:

-

Material Deformation Mechanism: Coining uses extreme pressure (100–1,000 MPa) to plastically deform metal, forcing it to flow into the exact shape of the punch and die cavities. This compression eliminates porosity and ensures full material contact with tooling, resulting in sharp, detailed features—even microscale patterns (0.1mm or smaller). Unlike embossing (which stretches material), coining compresses the metal, maintaining thickness or even slightly reducing it in the formed area.

-

Tight Tolerances & Surface Finish: The process achieves dimensional tolerances of ±0.005mm and surface finishes as smooth as Ra 0.02μm, surpassing most other stamping methods. This precision makes coining suitable for parts requiring tight fits or aesthetic perfection, such as gear teeth, electronic connectors, or decorative emblems.

-

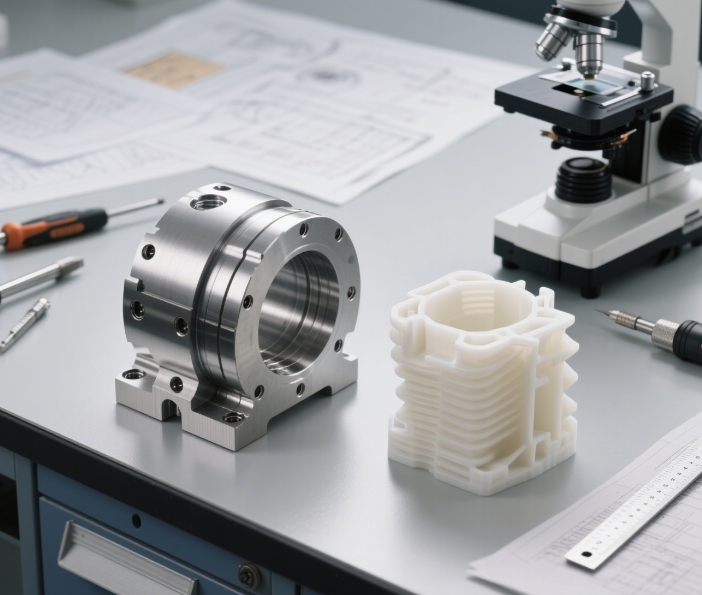

Hardened Tooling: Punches and dies are made from high-strength materials like tool steel (D2, A2) or carbide, heat-treated to 58–62 HRC for wear resistance. The tooling must be machined to mirror-finish precision to transfer details accurately to the metal, as any imperfection in the die will replicate on the part.

2. Step-by-Step Coining Process

The process follows a structured workflow to ensure precision and repeatability:

-

Material Preparation:

Coining works best with soft, ductile metals that flow easily under pressure. Common materials include:- Precious metals (gold, silver) for coins and jewelry.

- Copper, brass, and aluminum for decorative or electrical parts.

- Annealed steel (softened via heat treatment) for functional components like gears.

The metal blank is cleaned to remove oils or oxides, ensuring uniform deformation and preventing tool contamination.

-

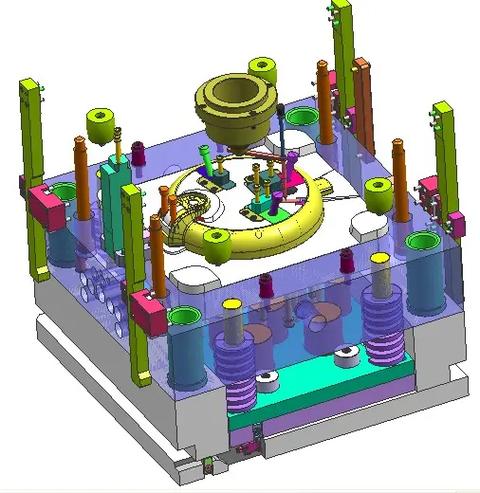

Tooling Setup:

The punch (upper tool with the desired pattern) and die (lower tool with a matching cavity) are mounted in a hydraulic or mechanical press. Alignment is critical—even 0.01mm misalignment can distort features or damage tooling. For complex parts, multiple dies may be used in sequence to build up features gradually. -

Coining Press Operation:

The blank is placed in the die cavity, and the press applies high pressure (typically 20–500 tons, depending on part size and material). The pressure forces the metal to flow into every detail of the tooling, from raised text to intricate 花纹. For deep or complex features, multiple passes may be used, with intermediate annealing to relieve work hardening in materials like brass or steel. -

Ejection & Inspection:

After pressure is released, the part is ejected from the die. Due to the high pressure, parts may stick to the punch, requiring ejector pins or air blasts to remove them. Inspection uses microscopy or CMMs to verify feature accuracy, surface finish, and dimensional consistency.

3. Materials Suited for Coining

Material selection is critical for successful coining, as ductility and flowability determine feature sharpness:

-

Soft Metals:

- Copper & Brass: High ductility (elongation 30–60%) allows them to flow into fine details, making them ideal for decorative parts, electrical contacts, and coins. Brass (C26000) is a favorite for its golden appearance and excellent formability.

- Aluminum Alloys (1100, 3003): Pure aluminum (1100) offers superior flowability for intricate patterns, while 3003 aluminum balances formability with strength for functional parts like switch contacts.

-

Precious Metals:

- Gold (24k, 18k) and silver are easily coined into detailed jewelry, medals, and coins due to their malleability. Alloying with copper (e.g., 18k gold = 75% gold + 25% copper) improves durability without sacrificing formability.

-

Steel & Stainless Steel:

- Low-carbon steel (1018) can be coined after annealing, but requires higher pressure than non-ferrous metals. It is used for precision components like gear teeth or valve seats.

- Stainless steel (304) is harder to coin but possible with annealed blanks, producing corrosion-resistant parts like medical device components or decorative trim.

4. Applications Across Industries

Coining’s precision and versatility make it indispensable in several sectors:

-

Numismatics & Medals: Coins, commemorative medals, and badges rely on coining to create sharp, long-lasting designs. For example, U.S. quarters use coining to define the intricate state emblems and text, ensuring clarity even after years of circulation.

-

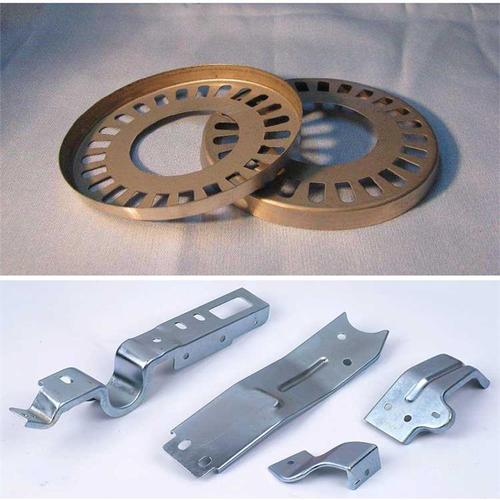

Electronics & Electrical Components:

- Connectors & Contacts: Coined copper or brass terminals have precise mating surfaces and conductive paths, ensuring reliable electrical connections in smartphones, computers, and automotive wiring.

- Switches & Relays: Coined features like contact points or lever arms provide consistent dimensions for smooth operation and long life.

-

Aerospace & Medical Devices:

- Precision components like sensor housings or valve stems use coining to achieve tight tolerances (±0.002mm) and smooth surfaces, critical for performance in harsh or sterile environments.

- Medical implants (e.g., titanium dental abutments) may use coining to create textured surfaces that promote bone integration, with microscale features formed via precision tooling.

-

Decorative & Luxury Goods:

- Jewelry (rings, pendants) uses coining to imprint patterns or text, leveraging precious metals’ malleability for intricate designs.

- High-end consumer goods (watches, luxury appliance trim) feature coined logos or textures for a premium, scratch-resistant finish.

5. Advantages & Limitations of Coining

-

Advantages:

- Exceptional Precision: Tighter tolerances and sharper features than embossing or casting, reducing the need for post-processing.

- Strength & Durability: Compression strengthens the metal (work hardening), increasing wear resistance—critical for coins or high-use components.

- Material Efficiency: No material is removed, minimizing waste compared to machining.

-

Limitations:

- High Tooling Costs: Precision dies are expensive to fabricate, making coining cost-effective only for high-volume production (10,000+ parts) or high-value items (jewelry, coins).

- Thickness Restrictions: Works best with thin to medium gauges (0.1–3mm). Thicker materials require excessive pressure, risking tool damage.

- Material Restrictions: Limited to ductile metals; brittle materials (high-carbon steel, titanium) may crack under pressure unless annealed.

6. Coining vs. Similar Processes

Coining is often confused with embossing or forging, but differs in key ways:

- Coining vs. Embossing: Embossing stretches metal to create raised features, often leaving the backside with a corresponding indentation. Coining compresses metal, creating sharper features with minimal thickness change and no backside distortion.

- Coining vs. Forging: Forging shapes large, thick parts with heat and pressure, while coining focuses on small, thin parts with fine details at room temperature (cold coining) or moderate heat (warm coining for harder materials).

Coining’s ability to produce precise, durable, and detailed metal parts makes it a critical process in industries ranging from electronics to luxury goods. By leveraging high pressure and precision tooling, it transforms ductile metals into components that balance functionality, aesthetics, and reliability.