II. Tool Chatter Types and Schematic Diagrams (Mark Key Vibration Zones)

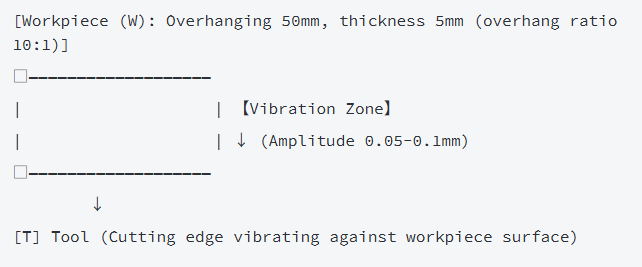

1. Low-Frequency Chatter (50-500Hz)

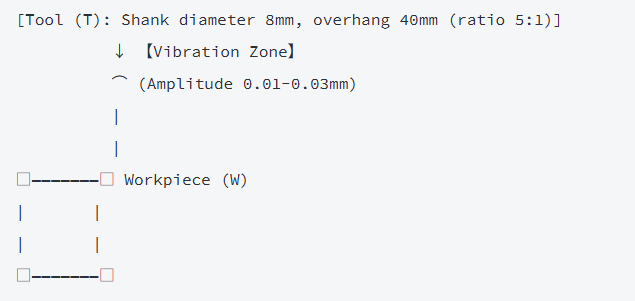

2. High-Frequency Chatter (1000-5000Hz)

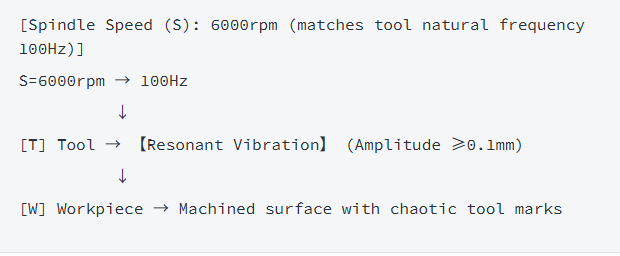

3. Resonant Chatter (Critical Frequency)

III. Four-Step Emergency Handling for Tool Chatter

Step 1: Pause Machining and Assess Impact

- Press the “feed hold” button (not emergency stop) to stop cutting; do not move the tool or workpiece immediately;

- Check two key impacts:

Step 2: Troubleshoot Chatter Causes (with Detection Methods)

Cause 1: Insufficient System Rigidity (40% of Cases)

- Typical Issues: Workpiece overhang too long, fixture clamping loose, tool overhang excessive;

- Detection Method:

-

- Tap the workpiece with a small hammer—prolonged vibration (>2s) indicates low rigidity;

-

- Check tool overhang: For carbide end mills, overhang ratio ≤3:1 (e.g., φ10mm tool overhang ≤30mm);

- Solution:

-

- Add support blocks for overhanging workpieces;

-

- Re-clamp the fixture (torque wrench for uniform force, e.g., 25N·m for M8 bolts);

-

- Replace with shorter tool holders (reduce overhang by 50%).

Cause 2: Improper Cutting Parameters (35% of Cases)

- Typical Issues: Spindle speed too high/low, feed rate too slow, cutting depth excessive;

- Detection Method:

-

- Use the “chatter test”: Increase spindle speed by 10%—if noise reduces, speed was too low;

-

- Check cutting depth: For aluminum alloy, finish milling depth ≤0.2mm (excessive depth increases vibration);

- Solution:

-

- Adjust spindle speed (e.g., reduce by 20% for high-frequency chatter, increase by 15% for low-frequency);

-

- Increase feed rate (e.g., from 800mm/min to 1200mm/min for plastic machining);

-

- Reduce cutting depth by 30%-50% (prioritize multiple passes over deep single passes).

Cause 3: Tool Issues (15% of Cases)

- Typical Issues: Dull cutting edge, tool runout excessive (>0.01mm), incorrect tool geometry;

- Detection Method:

-

- Check tool runout with a dial indicator (mount tool on spindle, rotate and measure);

-

- Test cut on scrap—dull tools cause “scraping” noise and burrs;

- Solution:

-

- Re-grind or replace dull tools;

-

- Use a tool setter to calibrate runout (replace collets if runout exceeds 0.01mm);

-

- Choose tools with larger core diameter (e.g., 0.7×tool diameter) for high-rigidity needs.

Cause 4: Machine Issues (10% of Cases)

- Typical Issues: Spindle bearing wear (runout >0.005mm), loose guideway screws;

- Detection Method:

-

- Measure spindle runout (static runout ≤0.005mm for precision machines);

-

- Check guideway clearance (push the slide with hands—no obvious play);

- Solution:

-

- Replace spindle bearings if runout exceeds limit;

-

- Tighten guideway screws (follow machine manual torque specs).

Step 3: Implement Remedial Measures

|

Chatter Type

|

Priority Measure

|

Expected Effect

|

|

Low-Frequency

|

Add workpiece support + reduce overhang

|

Vibration amplitude ≤0.02mm

|

|

High-Frequency

|

Shorten tool overhang + increase feed rate

|

Noise reduction by 50%

|

|

Resonant

|

Adjust spindle speed (±20%)

|

Resonance elimination

|

Step 4: Test Cut Verification

- Select a scrap piece of the same material;

- Use the adjusted parameters to machine a 50×50mm area;

- Check: ① No abnormal noise/vibration; ② Surface roughness Ra ≤0.8μm; ③ Dimensional error ≤±0.02mm—confirm qualified before formal machining.

IV. Core Prevention Measures for Tool Chatter

1. Design & Clamping Optimization (Pre-Machining)

- Workpiece Design: Avoid overhang ratios >5:1; add reinforcing ribs for thin-walled parts (thickness ≥1mm);

- Fixture Selection: Use vacuum chucks for large flat parts (vacuum degree ≥-0.08MPa); use side clamps for irregular parts (avoid single-point clamping);

- Tool Matching: For deep cavity machining, use modular tool holders (adjust overhang dynamically); choose indexable inserts with positive rake angles (reduce cutting force by 20%).

2. Parameter Setting Standards (Programming)

|

Material

|

Spindle Speed (rpm)

|

Feed Rate (mm/min)

|

Cutting Depth (mm)

|

Tool Overhang Ratio

|

|

Aluminum 6061

|

8000-12000

|

1200-2000

|

0.1-0.3 (Finish)

|

≤3:1

|

|

Stainless Steel 304

|

3000-5000

|

500-1000

|

0.05-0.2 (Finish)

|

≤2.5:1

|

|

ABS Plastic

|

6000-9000

|

1500-2500

|

0.2-0.5 (Finish)

|

≤4:1

|

3. Real-Time Monitoring (Machining)

- Sound Monitoring: Train operators to recognize chatter noise (differentiate from normal cutting “rustling”);

- Vibration Sensors: Install wireless vibration sensors (range 0-1000Hz) on the spindle—set alarm threshold at 0.05mm amplitude;

- Surface Inspection: Use a portable roughness tester to spot-check every 10 workpieces (Ra>1.6μm triggers parameter adjustment).

4. Machine Maintenance (Regular)

|

Maintenance Item

|

Cycle

|

Standard Requirement

|

|

Spindle Runout Check

|

Monthly

|

Static runout ≤0.005mm

|

|

Guideway Lubrication

|

Daily

|

Oil pressure ≥0.3MPa, no leakage

|

|

Tool Collet Cleaning

|

Weekly

|

No wear, runout ≤0.003mm after installation

|