1、Answer

The best aluminum alloy for CNC machining is 6061-T6, valued for its balanced performance: moderate strength (tensile strength ≥310MPa), excellent machinability (low tool wear), and good compatibility with surface treatments (e.g., anodizing), suitable for most structural parts.

Alternative options:

Alternative options:

- 7075-T6 (highest strength, tensile strength ≥572MPa): Used in aerospace and high-load scenarios but harder to machine (requires carbide tools);

- 5052-H32 (best corrosion resistance): Suitable for marine/chemical equipment but with lower strength (tensile strength ≤262MPa).

2、Expansion

Core Grade Characteristics and Selection Logic

-

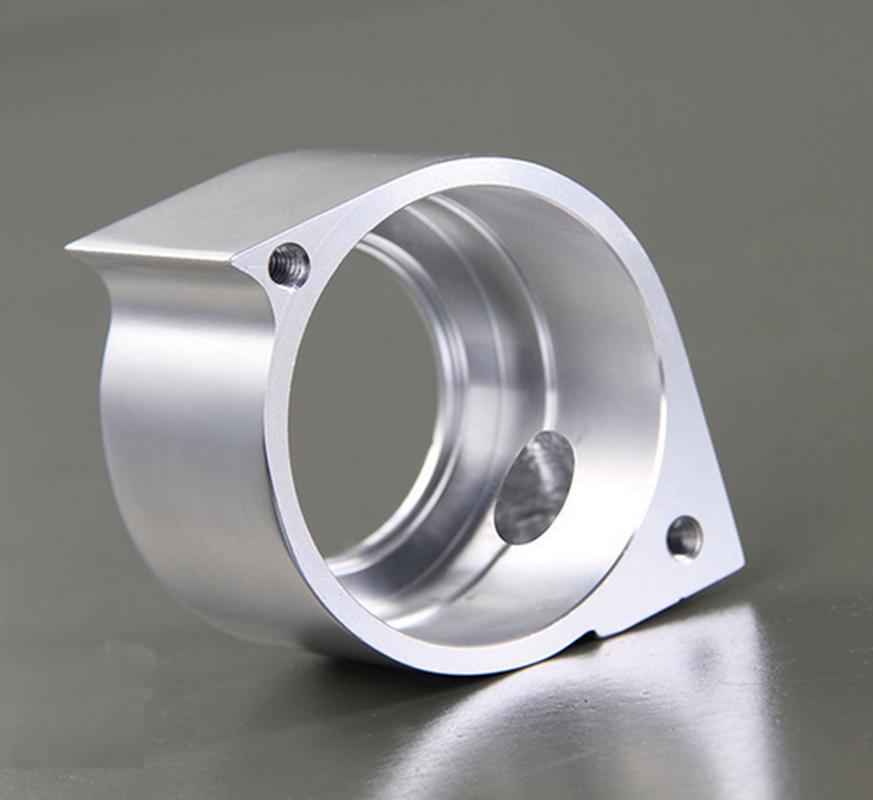

6061-T6: The “Versatile Choice” for CNC Machining

- Composition & Properties: Contains 1% silicon + 0.8% magnesium, strengthened via T6 heat treatment (solution annealing + artificial aging) while maintaining good ductility (elongation ≥12%).

- Machining Advantages:

- Low cutting resistance (30% less than 7075), compatible with high-speed steel (HSS) tools, feed rate up to 800mm/min;

- Low thermal expansion coefficient (23.6×10⁻⁶/℃), ideal for precision machining (tolerance ±0.02mm).

- Typical Applications:

- Mechanical parts (fixtures, gearboxes), drone frames (lightweight + vibration resistance), industrial radiators (thermal conductivity 180W/m·K).

-

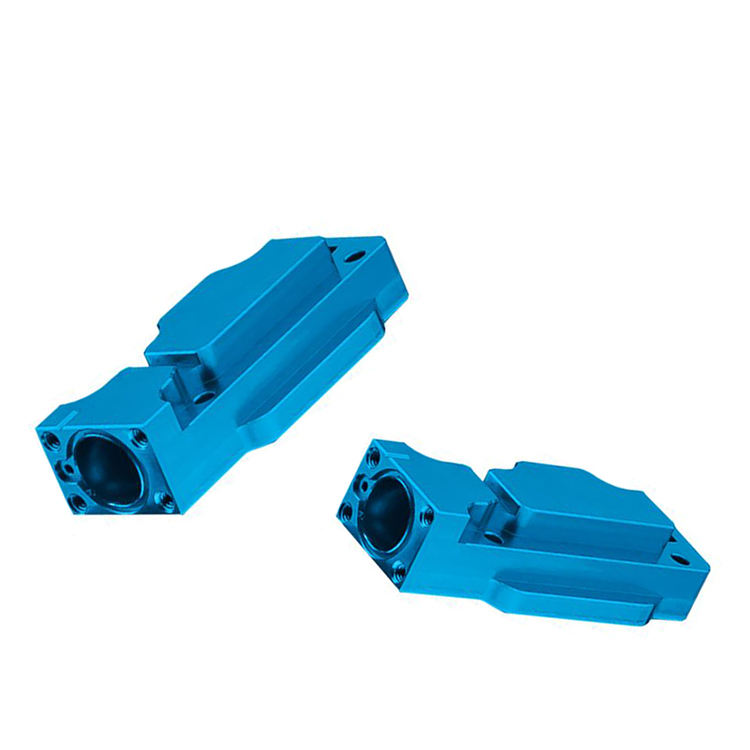

7075-T6: The “Performance King” for High-Strength Scenarios

- Composition & Properties: Contains 5.6% zinc + 2.5% magnesium, strength approaching steel (hardness HB≥150) but with poor corrosion resistance (requires plating protection).

- Machining Challenges:

- Prone to tool adhesion (needs diamond-coated or carbide tools, cutting speed ≤300mm/min);

- High residual stress (stress-relief annealing required after rough machining, adding 20% cost).

- Typical Applications:

- Aerospace structures (wing ribs, landing gear), racing components (30% weight reduction with 50% load increase), high-pressure valves (pressure resistance ≥20MPa).

-

5052-H32: The “Specialized Choice” for Corrosion Resistance

- Composition & Properties: Contains 2.5% magnesium (copper-free), strengthened via cold working (H32 = 1/4 hardening), salt spray corrosion resistance 5x that of 6061.

- Machining Limitations:

- Prone to built-up edge (feed rate must be reduced below 0.1mm/r);

- Unsuitable for high temperatures (service temperature ≤65℃).

- Typical Applications:

- Marine engineering parts (ship fittings, seawater pipelines), chemical equipment casings (acid/alkali resistance), laptop casings (smooth anodized surface).

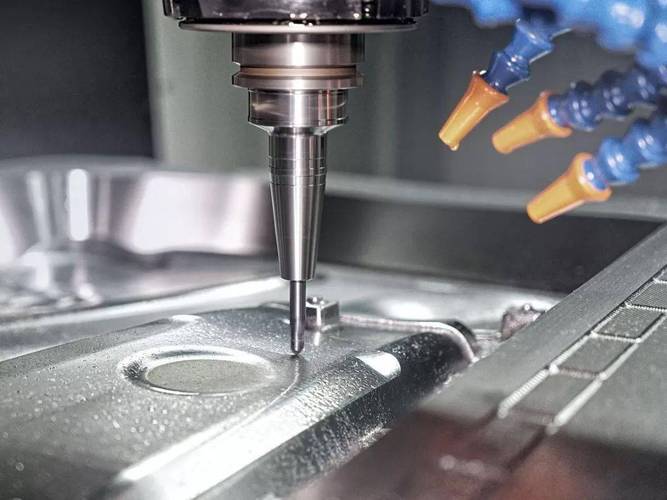

Machining Parameters and Cost Optimization

- Tool Selection:

- 6061 can use standard HSS end mills ($20–$50 per tool);

- 7075 requires tungsten carbide (WC) or PCD tools ($200–$800 per tool), with 5–10x longer lifespan.

- Coolant Strategies:

- Water-soluble coolant for 6061 (prioritizes cooling);

- Oil-based coolant for 7075 (prioritizes lubrication to prevent tool bonding).

- Cost Comparison (for 100 aluminum blocks):

Grade Material Cost/Unit Machining Time/Unit Total Time Total Cost 6061-T6 $15 30 minutes 50 hours $850 7075-T6 $25 1 hour 100 hours $1,750 5052-H32 $20 45 minutes 75 hours $1,275

Special Scenario Extensions

- High Surface Finish Requirements: 6063-T5 (0.35% silicon) is preferable, achieving surface roughness Ra0.8μm without secondary polishing (e.g., optical instrument casings).

- Extreme Lightweight Needs: 2024-T3 (4.4% copper) offers strength comparable to 7075 but with 3% lower density (2.78g/cm³), used for aerospace weight-sensitive parts (satellite brackets), though prone to discoloration after anodizing.

- Rapid Prototyping: Pre-machined 6061-T6 billets (e.g., Φ100mm aluminum rods) are readily available, saving 3 days of lead time compared to custom 7075 billets.

Conclusion: 6061-T6 is the best cost-effective choice for general applications; choose 7075-T6 for strength (accepting higher cost and machining difficulty); opt for 5052-H32 for corrosion resistance (sacrificing some strength). Actual selection should integrate part service environment, machine tool rigidity, and budget.